Understanding the Kanban system

The Kanban system is a project management and workflow visualization method that was originally developed by Toyota in the 1940s. The term "Kanban" is derived from the Japanese words "kan" (meaning "visual") and "ban" (meaning "card" or "board").

The Kanban system aims to improve efficiency, productivity, and collaboration by visualizing work and its flow through a series of visual cards or sticky notes. It provides a visual representation of tasks, their status, and the overall workflow, making it easier for teams to understand and manage their work.

Here are the key principles of the Kanban system:

- The Kanban board displays the different stages of the workflow, typically represented as columns. Each task or work item is represented by a card or sticky note that moves across the board as it progresses through the workflow.

- Kanban emphasizes the importance of limiting the number of tasks or work items that are in progress at any given time. This helps prevent bottlenecks and overloading team members, enabling a smoother flow of work.

- Kanban focuses on achieving a steady and continuous flow of work through the workflow stages. By identifying and addressing obstacles or delays, teams can optimize their processes and improve efficiency.

- Kanban encourages teams to define and document their policies and procedures for each workflow stage. These policies help establish guidelines for how work should be done, reducing ambiguity and promoting consistency.

- The Kanban system promotes a culture of continuous improvement. By monitoring and measuring the flow of work, teams can identify areas for improvement and make incremental changes to their processes over time.

Kanban is widely used in various industries and has gained popularity beyond its origins in manufacturing. It is particularly useful for managing agile software development, lean project management, and other knowledge work environments where flexibility and responsiveness are crucial.

Unveiling the Kanban Board: A Visual Tool for Streamlining Workflow and Improving Productivity.

Let's dig deeper on the Kanban Board

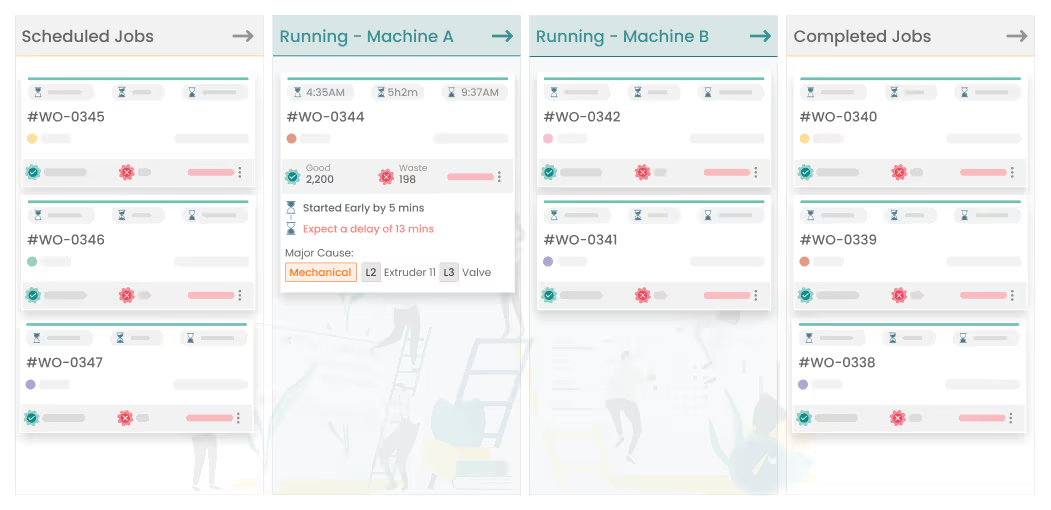

A Kanban board is a visual tool used to manage and track work items or tasks within a Kanban system. It provides a clear and organized representation of the workflow, allowing teams to visualize the progress of their work and optimize their productivity.

A typical Kanban board consists of a physical or digital surface divided into columns representing different stages of the workflow. Each column represents a specific step or status in the process. Common column labels include "To Do," "In Progress," and "Done," but they can be customized based on the team's workflow.

Work items, represented by cards or sticky notes, are placed on the Kanban board and move horizontally across the columns as they progress through the workflow. The team members responsible for each task can easily see what needs to be done, what is currently in progress, and what has been completed.

Kanban boards offer several benefits:

Visualization

The board provides a clear visual representation of work, making it easy for team members to understand the current status of tasks and the overall workflow.

Transparency

The entire team has visibility into the work items, facilitating collaboration, communication, and alignment.

Workflow management

The board helps identify bottlenecks, optimize the flow of work, and balance the workload across team members.

WIP limits

By setting limits on the number of work items allowed in each column, Kanban boards help prevent overloading and encourage focused work.

Continuous improvement

The board provides valuable data for analyzing cycle times, identifying areas for improvement, and implementing incremental changes to enhance efficiency.

Kanban boards can be physical boards using sticky notes or whiteboards, or they can be digital tools or project management software with virtual boards. Regardless of the format, the main purpose is to provide a visual representation of work and support the principles of the Kanban system.

Balancing Efficiency and Challenges: Exploring the Pros and Cons of the Kanban System on the Shopfloor.

Pros & Cons of the Kanban System on Shopfloor

The Kanban system offers several advantages and disadvantages. Here are some of the pros and cons of implementing a Kanban system:

Pros of Kanban:

Flexibility

Kanban is highly adaptable and can be applied to various industries and types of work. It allows teams to adjust their workflow based on changing priorities, making it suitable for dynamic and unpredictable environments.

Visualized Workflow

Kanban boards provide a clear visualization of work items and their progress through the workflow. This transparency promotes shared understanding, improves communication, and enables better collaboration among team members.

Workload Balancing

Kanban helps prevent the overloading of team members by setting explicit Work in Progress (WIP) limits for each workflow stage. This ensures a balanced distribution of work and reduces the likelihood of bottlenecks.

Continuous Improvement

Kanban emphasizes a culture of continuous improvement. By regularly analyzing and measuring the flow of work, teams can identify areas for optimization, make incremental changes, and continuously enhance their processes and productivity.

Customer Focus

Kanban places a strong emphasis on delivering value to the customer. By visualizing customer requests and prioritizing them in the workflow, teams can ensure that the most valuable work is given priority and delivered efficiently.

Cons of Kanban:

Lack of Predictability

Compared to time-boxed methodologies like Scrum, Kanban does not provide fixed timeframes for the completion of work. This can make it challenging to predict when specific tasks or projects will be completed, which may be a disadvantage for organizations with strict deadlines or time-sensitive projects.

Limited Structure

Kanban is less prescriptive in terms of roles, ceremonies, and predefined processes compared to methodologies like Scrum. This lack of structure can be a disadvantage for teams or organizations that prefer a more defined framework or are looking for specific guidelines to follow.

Complex Workflow Management

While Kanban boards help visualize the workflow, managing complex workflows with multiple dependencies and parallel processes can become challenging. It requires careful design and customization of the Kanban system to handle such complexities effectively.

Communication and Coordination

Kanban's focus on individual tasks and flow may require additional effort to ensure effective communication and coordination among team members. Without clear mechanisms for collaboration, it can be challenging to address dependencies and ensure a cohesive approach to work.

Dependency on External Factors

Kanban relies on a steady flow of work and external inputs. Delays in receiving necessary inputs or dependencies on external teams or stakeholders can disrupt the flow and impact productivity.

It's important to note that the pros and cons of Kanban can vary based on the specific context and requirements of each organization or project. It's recommended to assess these factors carefully before deciding to implement Kanban or any other project management approach.

Scrum-Style Board vs. Kanban Board: Understanding the Key Differences in Agile Workflow Management.

Scrum-Style Board vs. Kanban Board. Differences.

Work order management plays a vital role in streamlining and optimizing processes, projects, and routine tasks within an organization. By establishing a comprehensive organizational workflow, work order management ensures that teams have the necessary context and information to perform their work effectively. It provides stakeholders with an overview of ongoing, in-progress, and completed projects while highlighting how each piece of work contributes to overall business objectives and success.

Methodology (SCRUM vs Kanban)

Scrum, an iterative and time-boxed framework

Kanban, a continuous flow and pull-based framework

Planning

Sprint-based planning with fixed durations (e.g., 2 weeks)

No fixed durations; continuous workflow

Work Allocation

Fixed team roles and responsibilities

No fixed team roles; flexible work allocation

Work in Progress (WIP)

WIP limits are optional or used for the entire sprint

WIP limits are essential for each workflow stage

Work Scheduling

Sprint backlog with prioritized user stories/tasks

Continuous backlog; work items pulled as capacity allows

Iterative Development

Sprints with specific goals and deliverables

Continuous development and delivery

Daily Standup Meetings

Regular daily meetings to discuss progress and plan work

Meetings are optional and held as needed

Changes during a Sprint

Changes are discouraged during a sprint

Changes can be made at any time within the workflow

Retrospectives

Held at the end of each sprint to reflect and improve

Continuous improvement through cycle time analysis

Visualization

Often uses a task board with columns (To Do, In Progress, Done)

Also uses columns or swimlanes to visualize workflow

Team Autonomy

Self-organizing teams with defined roles

Flexible team structure and autonomy

It's important to note that Scrum and Kanban are both effective frameworks, and the choice between them depends on the specific needs and context of a project or organization. The table above highlights some of the general differences between the two approaches, but it's always recommended to assess the requirements and preferences before deciding which method to adopt.

Workorder Scheduling Software for Industry 4.0

Production Scheduling Software for Manufacturing

Production Workflow Management for Shopfloor

Agile Manufacturing Software Solution for Industry 4.0

Kanban integrates with Digital Manufacturing Software

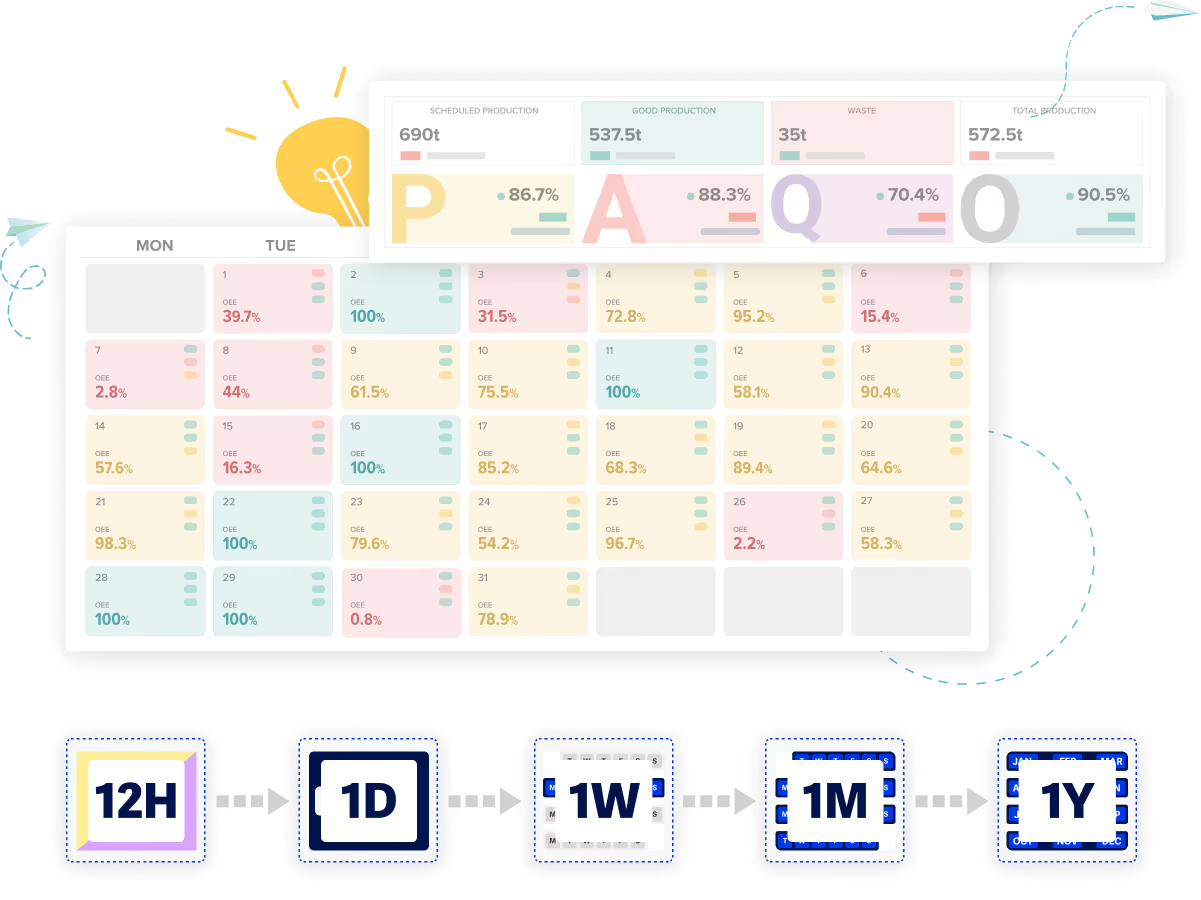

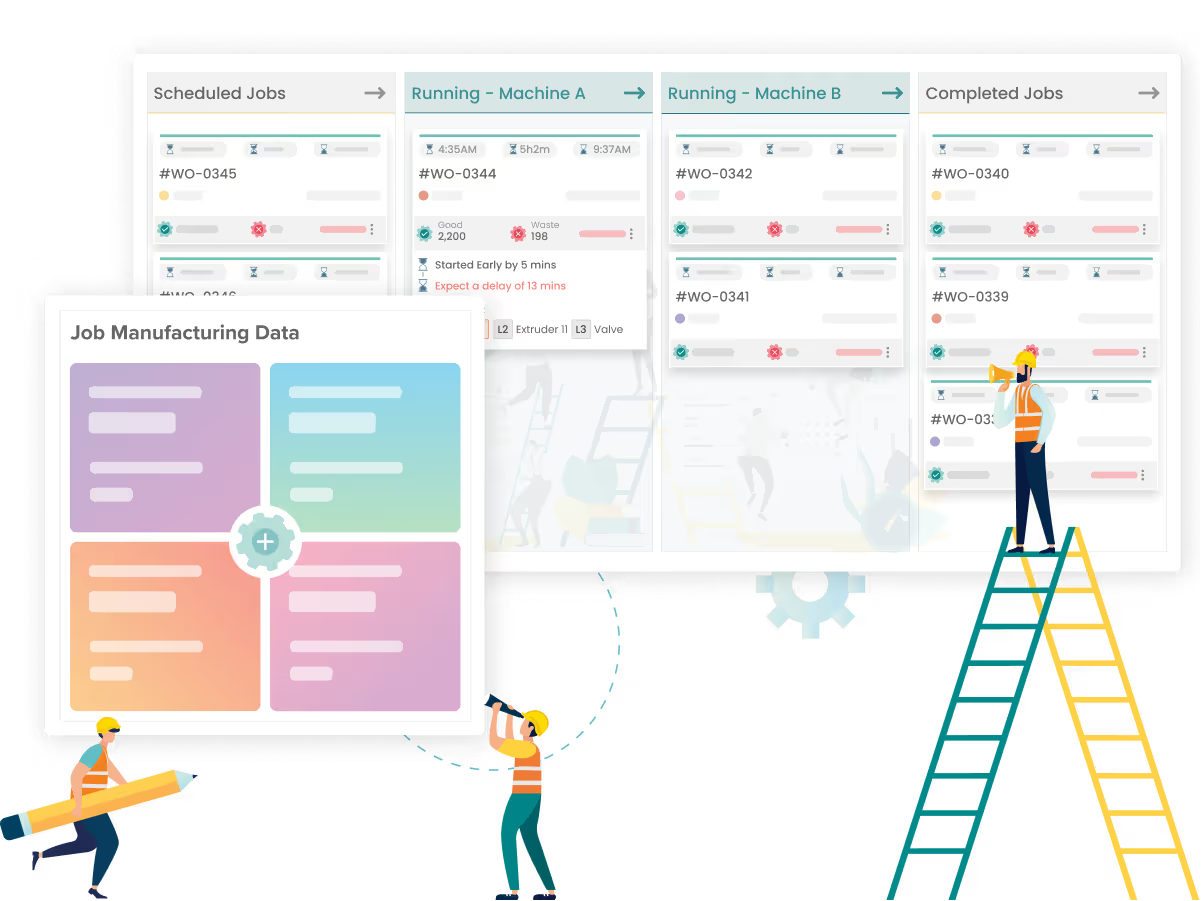

To achieve optimal productivity, manufacturers are increasingly turning to digital solutions that can streamline their operations. One such powerful combination is the integration of Kanban with Digital Manufacturing Software.

Kanban, a lean production method originating from the Toyota Production System, is widely recognized for its ability to visualize workflows, optimize inventory levels, and improve overall efficiency. Digital Manufacturing Software, on the other hand, provides advanced capabilities for process automation, data analytics, and real-time insights. When these two powerful tools join forces, manufacturers can unlock a new level of operational excellence.

By integrating Kanban with Digital Manufacturing Software, manufacturers can experience a range of benefits that enhance their production processes:

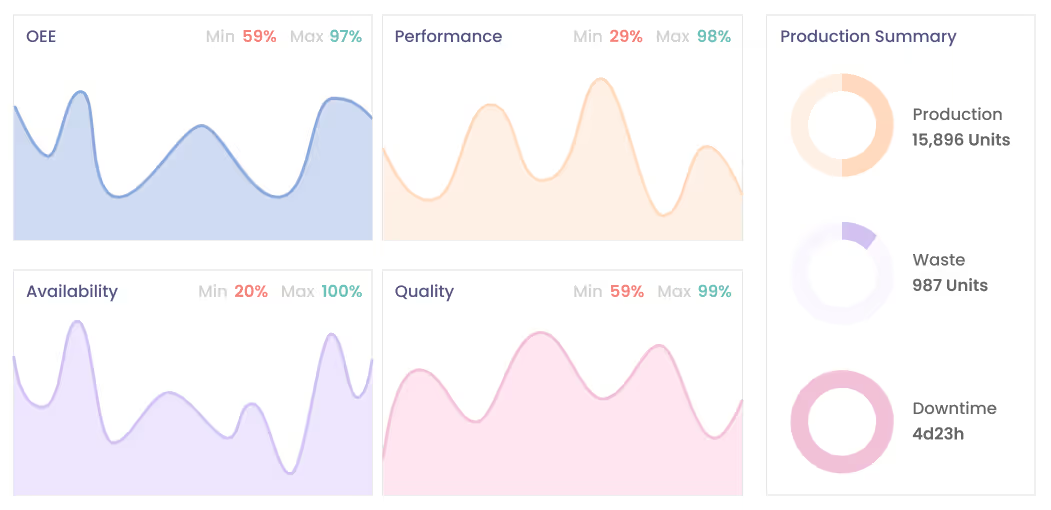

Enhanced Visibility

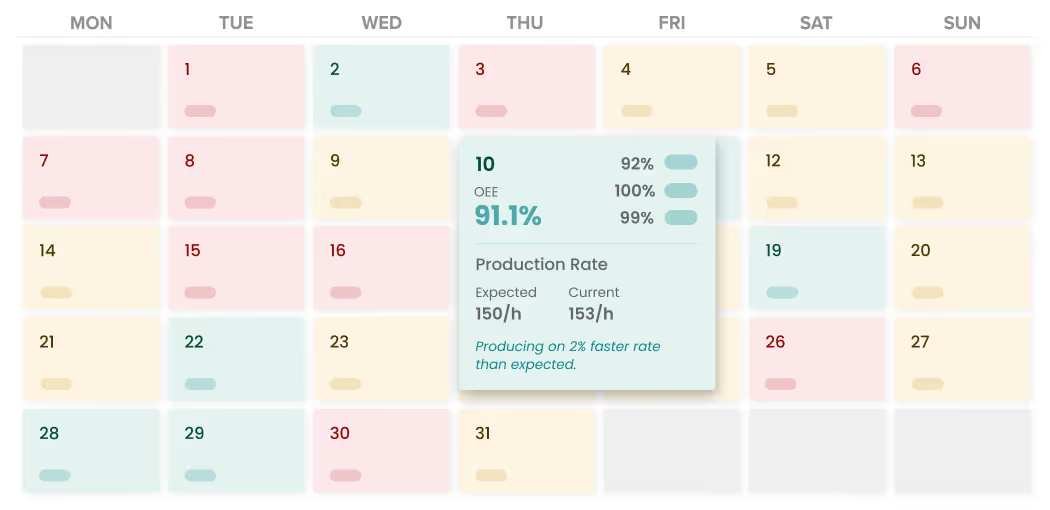

Kanban boards, whether physical or digital, provide a visual representation of production workflows, highlighting the status of each task and allowing teams to easily track progress. When integrated with Digital Manufacturing Software, this visibility is further enhanced, as real-time data from the software is seamlessly incorporated into the Kanban system.This ensures that the entire production team has access to up-to-date information and can make informed decisions based on accurate data.

Enhanced Visibility

Kanban's principles of limiting work in progress (WIP) and focusing on flow align perfectly with the capabilities of Digital Manufacturing Software. By integrating the two, manufacturers can establish a smooth and efficient workflow management system.

The software can automate task assignments based on the Kanban board, ensuring that work is evenly distributed and bottlenecks are minimized. This synchronization of Kanban and Digital Manufacturing Software enables seamless collaboration and improves overall process efficiency

Real-Time Production Insights

Digital Manufacturing Software provides real-time data and analytics, offering valuable insights into production performance, resource utilization, and cycle times. By integrating this data with the Kanban system, manufacturers can leverage these insights to optimize their production processes. They can identify areas for improvement, detect inefficiencies, and make data-driven decisions to enhance productivity and reduce lead times.

Accelerate Shopfloor Efficiency: Unlocking Reduced Lead Time for Enhanced Performance.

Ready to Increase your Shopfloor Lead Time?

Increase productivity with our smart factory software and take your manufacturing operations to new heights. Our powerful solution is designed to streamline processes, optimize resource allocation, and provide real-time insights into production performance.

By implementing our smart factory software, you can:

Improve Workflow Efficiency

Automate manual tasks, eliminate bottlenecks, and ensure smooth workflow execution. Experience streamlined operations, reduced lead times, and increased throughput for enhanced productivity.

Optimize Resource Allocation

Gain real-time visibility into resource utilization and allocate resources effectively based on demand and capacity. Minimize downtime and maximize production output with efficient resource management.

Gain Actionable Insights

Leverage advanced analytics to uncover valuable insights into production performance, quality metrics, and predictive maintenance. Make proactive decisions, optimize processes, and drive continuous productivity gains.

Foster Collaboration

Facilitate seamless communication and collaboration between teams, promoting a culture of teamwork and efficient information sharing. Ensure everyone is aligned and working towards common goals for increased productivity.

Experience the transformative power of our smart factory software and unlock new levels of efficiency and profitability. Contact us today to learn how our solution can revolutionize your manufacturing operations and drive productivity gains. Let's embark on this journey together and achieve manufacturing excellence. Get Started today.

Why should you care? And what to do if you do.

Increase productivity with our smart factory software and take your manufacturing operations to new heights. Our powerful solution is designed to streamline processes, optimize resource allocation, and provide real-time insights into production performance.

By implementing our smart factory software, you can:

Improve Workflow Efficiency

Automate manual tasks, eliminate bottlenecks, and ensure smooth workflow execution. Experience streamlined operations, reduced lead times, and increased throughput for enhanced productivity.

Optimize Resource Allocation

Gain real-time visibility into resource utilization and allocate resources effectively based on demand and capacity. Minimize downtime and maximize production output with efficient resource management.

Gain Actionable Insights

Leverage advanced analytics to uncover valuable insights into production performance, quality metrics, and predictive maintenance. Make proactive decisions, optimize processes, and drive continuous productivity gains.

Foster Collaboration

Facilitate seamless communication and collaboration between teams, promoting a culture of teamwork and efficient information sharing. Ensure everyone is aligned and working towards common goals for increased productivity.

Ready to make the smart move?

Experience the transformative power of our smart factory software and unlock new levels of efficiency and profitability. Contact us today to learn how our solution can revolutionize your manufacturing operations and drive productivity gains. Let's embark on this journey together and achieve manufacturing excellence. Book Live Demo now.