The machinery and equipment manufacturing industry faces several challenges that hinder productivity, including manual processes, paperwork, siloed data, and low OEE. The workforce struggles to focus on manufacturing in the absence of digital automation, and a lack of modern software only exacerbates the issue.

Kypeco MES enables end-to-end automation for machinery and equipment manufacturing, from production planning to quality control. It eliminates manual processes, improves OEE, and reduces downtime. With Kypeco MES, the workforce can focus on high-value activities and make data-driven decisions, resulting in improved productivity and profitability. Additionally, Kypeco MES provides real-time monitoring, automated reports, and predictive maintenance, reducing costs and increasing efficiency. By digitalizing manufacturing processes and progressing towards Industry 4.0, Kypeco MES ensures readiness for the future of manufacturing.

Transform your manufacturing operations with the digital MES smart apps, shifting away from traditional paper-based and whiteboard systems to boost efficiency and optimized processes with our digital MES platform.

Upgrade to digitalization, futuristics MES analytics, and innovative technologies to optimize operations, and accelerate time-to-market.

Integrating cloud and industrial tech improves safety, quality, and compliance while reducing costs with our digital MES.

MES Re-evaluate Production Processes or regular process reviews can keep manufacturing operation lean and agile.

Gain valuable insights and drive continuous improvement across operations by experimenting with data-driven digital MES.

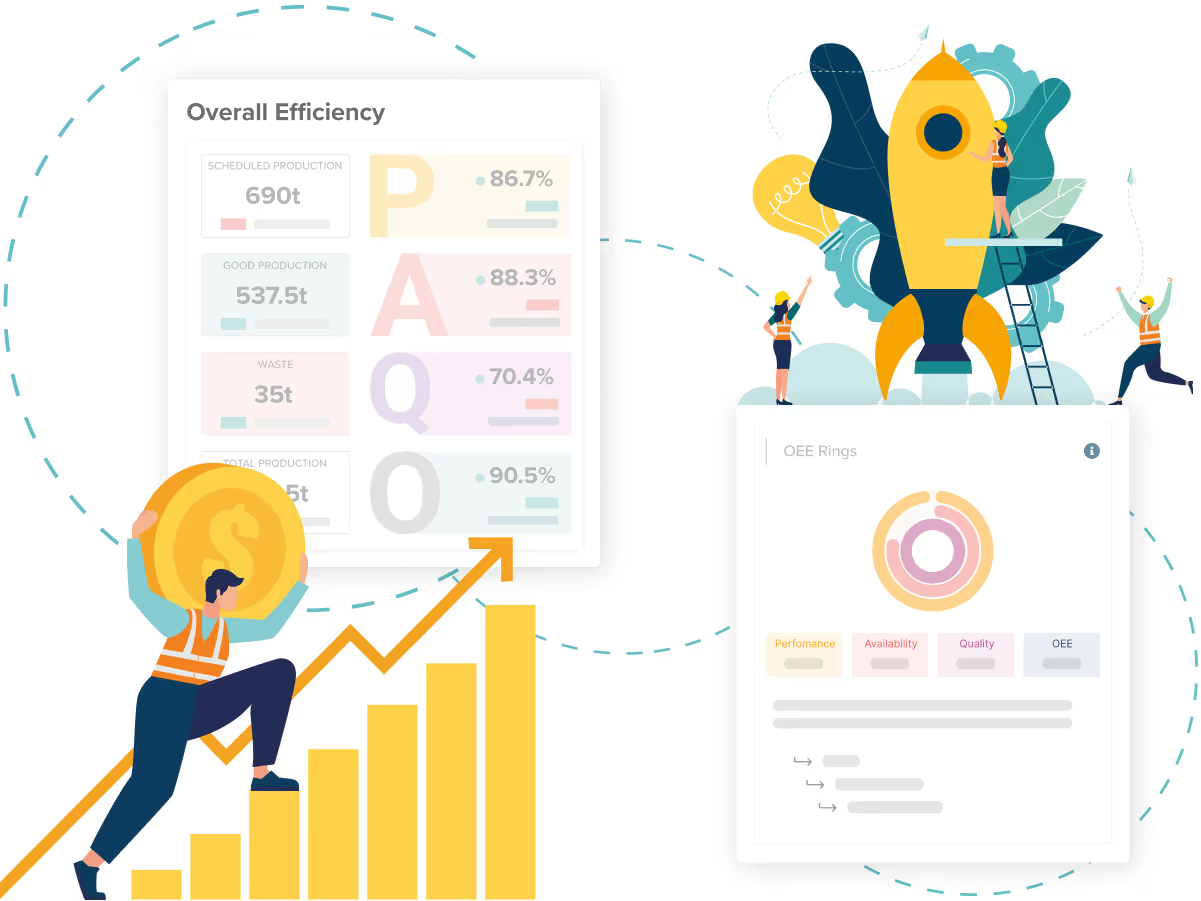

With the digital MES, unleash the full potential of your operations by optimizing performance, availability, and quality. Enhance efficiency, reduce waste, and ensure consistent delivery of high-quality products in machinery equipment manufacturing.

Providing real-time insights with our MES, enabling prompt interventions, and driving continuous line performance improvement .

Improve visibility into operations and enhance business performance with the MES production line dashboard.

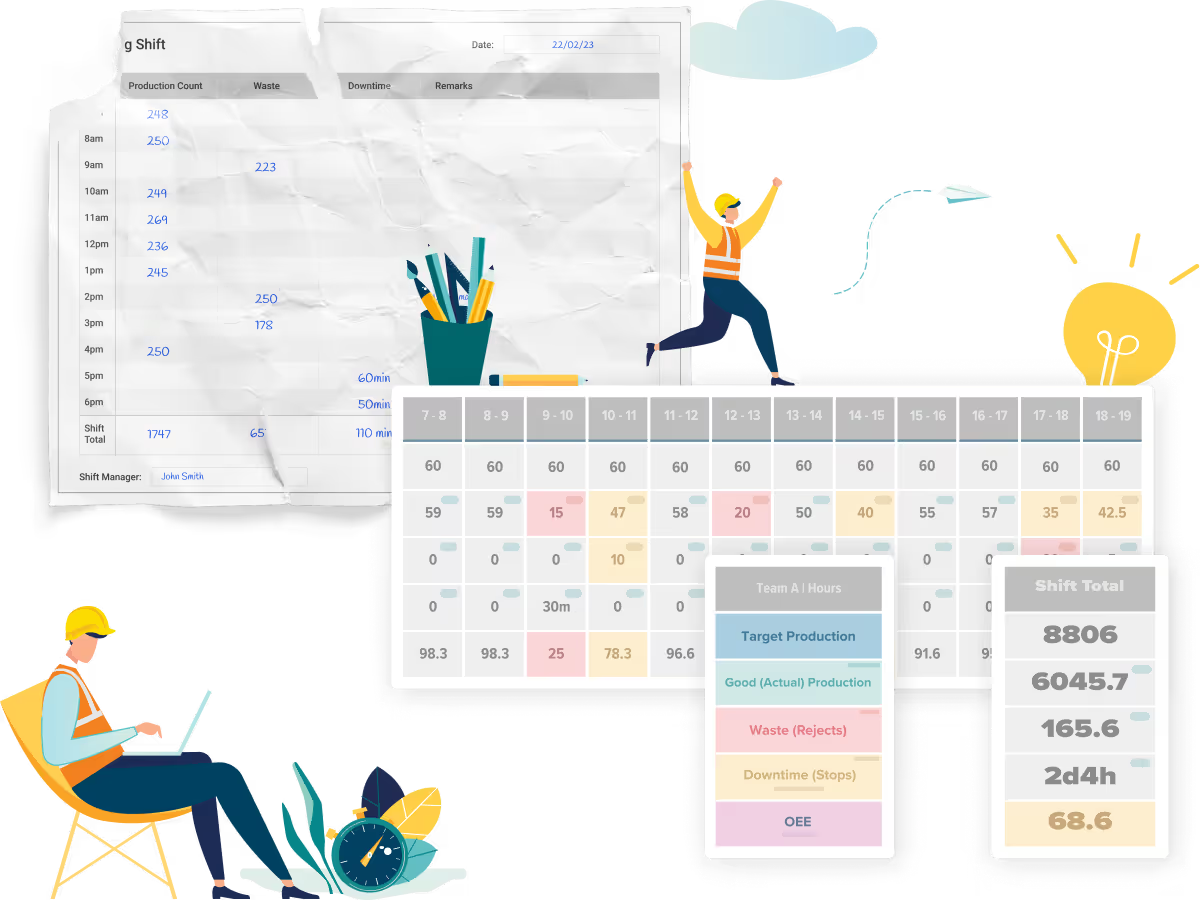

Enables better planning, scheduling, and coordination, leading to optimized productivity with MES pacing board.

With MES, Monitor failure reasons, prioritize corrective actions, and continuously improve operations.

Modernize your workplace to appeal to the younger generation. Embrace modern MES technology-driven solutions that eliminate paperwork headaches and foster productivity in machinery equipment manufacturing industry.

With our MES, store and manage digital documents more efficiently, making it easier to find and retrieve information without any use of paper.

A digital workplace that values teamwork, and innovation can build a culture that appeals to younger workers with the MES.

Our MES outlook for manufacturing is evolving rapidly, and whoever adapt and innovate are best positioned for success in the years ahead.

Unlock productivity with mobile accessibility. Empower younger employees to work efficiently on their preferred devices.

By utilizing MTBF, MTTR, and MTTF insights, manufacturers can optimize maintenance activities, reduce equipment downtime, and improve asset longevity and they can do it with the help of an advanced MES platform.

Empower asset management initiatives with advanced MES and actionable insights derived from robust metrics.

Measure downtime frequency with Mean Time Between Failures to enhance maintenance planning and minimize disruptions.

Critical metric for determining the average time it takes to repair equipment, optimize maintenance schedules.

Utilize Mean Time to Failure to optimize asset lifespan, reduce unplanned failures, and maximize operational efficiency.

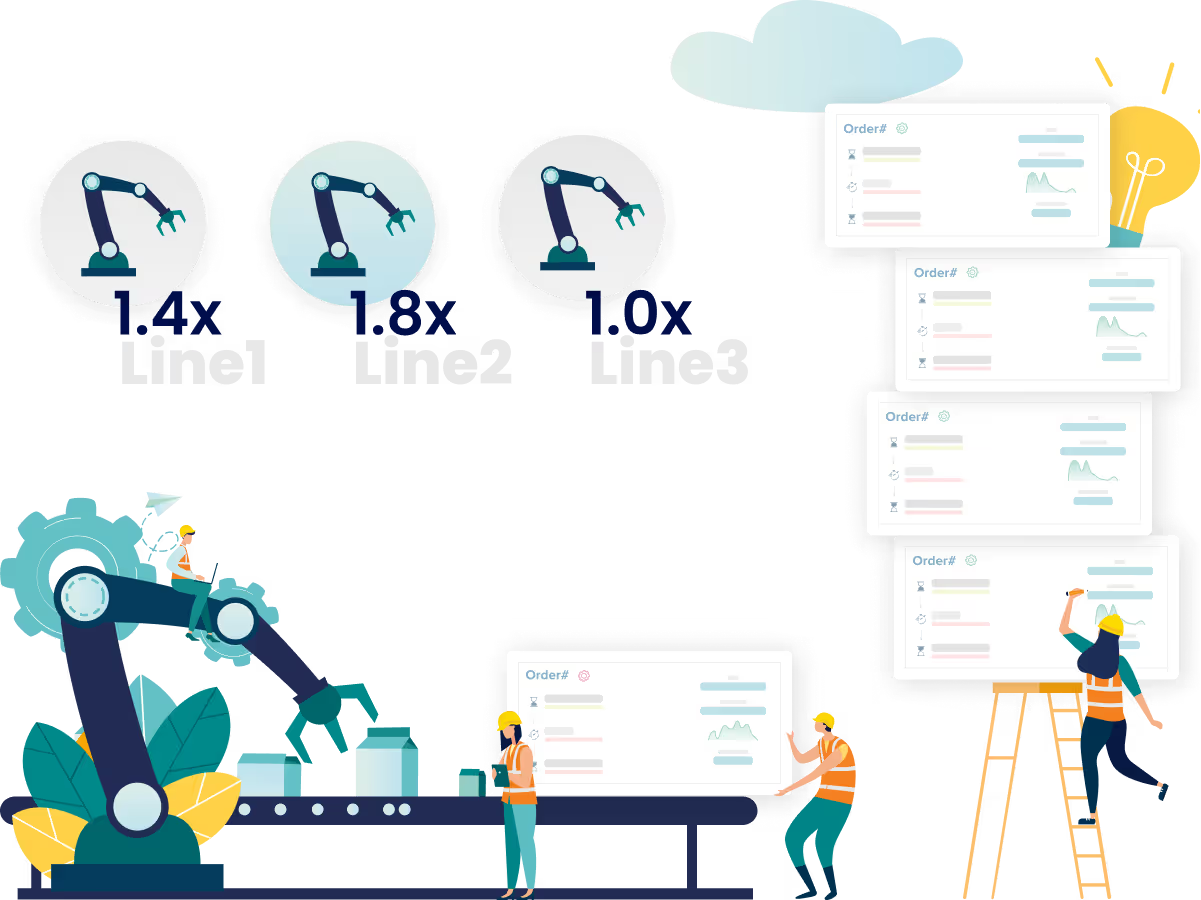

Optimize work order management with a powerful smart scheduler, leveraging machine learning and AI for efficient task allocation and resource optimization in your machinery equipment industry.

Maximize work order scheduling effectiveness through data-driven decision-making, optimizing resource utilization.

Achieve smooth work order management with our flexible digital MES visualization options, optimizing resource utilization.

Automate the scheduling process with our MES and improve overall productivity, reducing manual work.

Connect work order management with ERP and e-commerce platforms, driving efficient processes with our digital MES.

With the help of our latest MES platform, empower your maintenance team with a robust planning and scheduling solution, making it easy to coordinate tasks and ensure smooth operations for maximum efficiency.

Achieve efficient maintenance planning through visual tools, enabling clear task visualization and upgrade workflow management with the help of our MES.

Effortlessly track work orders using our MES, enhancing coordination and productivity.

Plan and schedule recurring maintenance tasks with ease for better asset performance.

Improve equipment uptime with well-defined breakdown maintenance SOPs in machinery equipment industry.

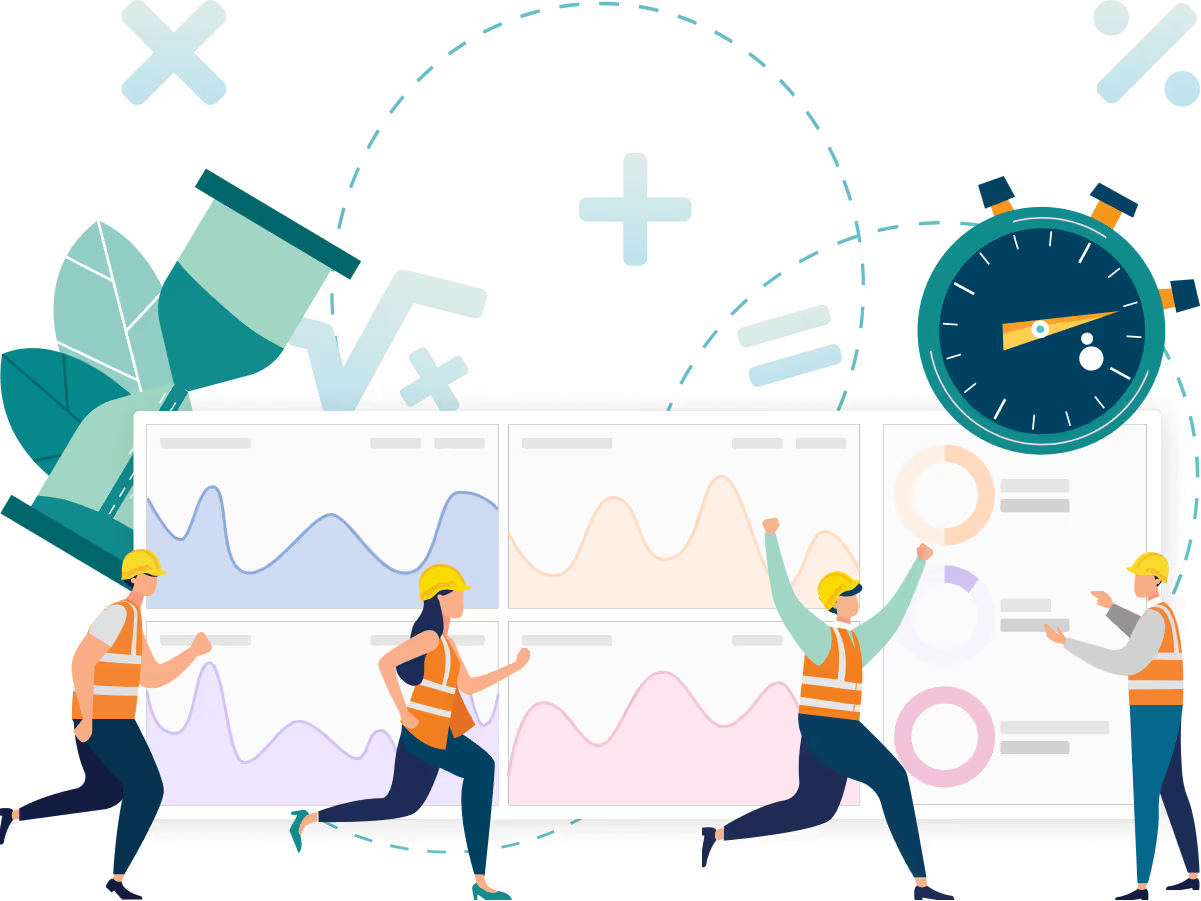

Enhance decision-making capabilities with our modern digital platform for automated and real-time reporting, providing comprehensive insights into machinery equipment manufacturing operations.

Embrace a paperless revolution, leveraging automated reports to eliminate paperwork and whiteboards for efficient operations.

Get visibility into operations, optimize manufacturing operations with intuitive and easy-to-use MES platform.

Drive organizational agility with paperless tools tailored for business transformation leaders, accelerating results.

Enable financial executives to make informed decisions with data-driven insights from advanced reporting capabilities.

Update team collaboration and optimize decision-making with comprehensive data insights, reducing inefficiencies with the help of our MES platform’s Transparent and Centralized Data in your machinery equipment manufacturing industry.

Unlock the power of interconnected data by removing silos, empowering organisations with a holistic view and collaborative synergy.

Unlock the power of interconnected data by removing silos, enabling organisations with a holistic view with our MES.

Connect and empower teams with a centralized digital MES solution, promoting collaboration and inclusivity.

Drive continuous improvement and employee engagement with a feedback loop that values and acts on input with modern MES.

Gain a competitive edge by leveraging your manufacturing data, extracting valuable insights that inform proactive and strategic decision-making.

Unlock the potential of manufacturing data to drive strategic decision-making and optimize operations with our MES platform.

Pinpoint the underlying reasons for problems with digital platform, improving performance across overall operations.

Analyze production trends to uncover valuable insights for strategic decision-making and performance optimization.

Maximize profits by optimizing costs and minimizing losses with data-driven insights and smarter processes.

Take full control with a white-label MES platform that allows you to customize it to your branding, locale, and manufacturing processes with our digital manufacturing tool.

Personalize the Kypeco platform to suit your manufacturing workflows, facilitating data integration, analysis, and actionable insights.

Monitor production and metrics for real-time visibility and performance management with our MES.

Tailor the Kypeco platform to your brand identity and preferred language for a cohesive user experience.

Efficiently manage inventory, reduce waste, and minimize errors with customized SKUs and assets.

120+

Our real-time alerting system notifies users of critical data changes or anomalies in real-time, enabling swift actions, and helping in real-time data visibility.

MES's data auditing and monitoring capabilities enable organizations to maintain consistent and accurate data.

Our MES's advanced search capabilities enable teams to quickly find and access relevant data, reducing the impact of data silos.

Our data lineage tracking capabilities enable industries to trace the origin and flow of data, promoting traceability.

MES enables manufacturing industries to compare their production processes to industry best practices, promoting manufacturing process optimization.

With the help of our MES, enable dynamic production planning, allowing rapid adjustments to align with changing demand scenarios.

With the help of our production scheduling capabilities optimize production schedules, reducing lead times and improving efficiency, helps in overcome from this challenge.

Our data visualization tools provide a clear and concise view of processes, enabling quick insights into bottlenecks and inefficiencies.

Kypeco's remote monitoring capabilities enable industries to monitor equipment processing and maintenance activities from remote locations.

Our MES helps industries to plan and execute tasks more accurately, reduce downtime & identify bottlenecks in production.

With the help of our MES, we enable industries to test and optimize production processes, thereby reducing waste & scrap caused by process inefficiencies.

Our digital reporting capabilities enable industries to generate financial reports that provide detailed information on production costs, facilitating cost tracking.

This capability enables manufacturing industries to develop products more efficiently and accurately, enhancing competitiveness and customer value.

MES enables industries to offer flexible work options, improving work-life balance and attracting of skilled workforce.

MES enables industries to provide employees with open and effective communication channels and feedback opportunities on manufacturing data which helps in retaining an experienced workforce.

Kypeco's process optimization capabilities enable industries to optimize their processes, preventing bottlenecks and enhancing process efficiency.

Our MES enables the creation of teams of employees from different departments, enhancing collaboration. Teams can contribute to other departments using data analytics that gives them in-depth knowledge of other manufacturing areas.

Our digital MES, enables industries to manage workflows and tasks effectively, reducing manual labor costs.

With our digital MES, track production costs accurately, identify areas for cost optimization, and enhance process efficiency.

Kypeco's real-time data enables manufacturing industries to access and analyze data in real-time, enhancing decision-making speed.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the machinery & equipment industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your machinery & equipment manufacturing operations.