Manufacturing industries face various challenges that result in inefficiencies, missed deadlines, and quality issues. Manual processes, paperwork, and siloed data are some of the major pain points that result in increased production costs and lost revenue. The lack of modern software and automation increases technical debt and slows down progress, while the workforce struggles to focus on manufacturing in the absence of digital tools.

However, modern digital solutions are transforming the manufacturing industry by optimizing production processes and improving efficiency. Manufacturers today use software solutions to monitor production lines, identify bottlenecks, and automate repetitive tasks, making the team more efficient and attracting the younger workforce. By adopting Kypeco, manufacturers can reduce errors, increase productivity, optimize resources, and automate reports without manual paperwork.

Smart software solutions have become a necessity for companies that want to improve OEE and quality and reduce downtime. The use of ML and AI helps manufacturers gain end-to-end manufacturing visibility and make data-driven decisions. By digitalizing their manufacturing processes, manufacturers can achieve greater agility, attract a younger workforce, and progress toward smart industry readiness.

Manufacturing teams face challenges with inventory management, quality control, and process optimization. Digitalization can help streamline workflows and improve productivity, but requires a shift in mindset towards technology adoption.

Discover efficient, lean operations, automated reports, reduced costs, and swift production for a competitive edge.

Embrace IoT, AI, and cloud computing to automate, streamline processes, and boost overall manufacturing efficiency.

Analyze and refine processes, pinpoint improvement areas, and minimize waste for optimal performance.

Leverage Smart Digital Solutions to enhance efficiency and thrive in a rapidly evolving manufacturing landscape.

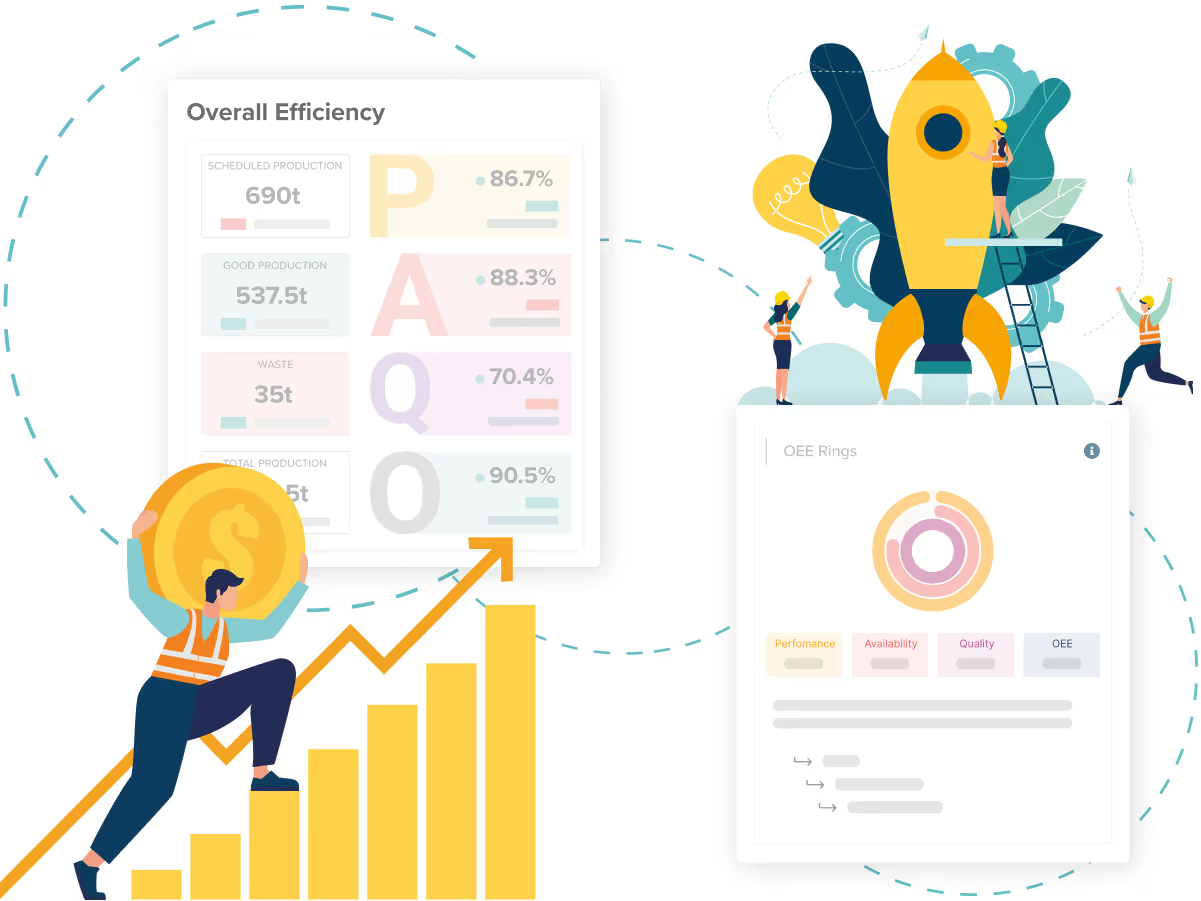

To succeed in today's business world, it's essential to maximize efficiency and productivity. By improving performance, availability, and quality, you can stay ahead of the competition and you can do it with our MES.

Monitor line efficiency in real-time, gaining insights on equipment usage, cycle time, OEE, and more.

Track assembly line live status, production rate, cycle time, quality control, and OEE.

Display production targets, good production, waste, downtime, and line performance.

Identify root causes of production failures, downtime, and equipment issues.

Younger workers are often more comfortable using technology, and by adopting our latest MES, create a more modern, dynamic workplace that attracts and retains top talent.

By going paperless with a Manufacturing Execution Systems, Reduce the costs associated with printing, storing, and managing paper documents.

Build a workplace that attracts and engages younger workers with modern MES technology and flexible work arrangements.

Outlook for manufacturing is strong, with advances in technology, automation, and innovation driving growth and productivity in automotive industry.

Creating a digital MES workplace that is mobile-friendly, accessible, and user-friendly can help attract younger workers.

Utilize key metrics for insights on production asset performance, enabling proactive maintenance improvements, reduced downtime, and enhanced production efficiency.

Monitor equipment utilization, maintenance effectiveness, and optimize asset usage by tracking and evaluating asset performance.

Assess asset availability and reliability to determine the frequency of production asset failures and improve uptime.

Evaluate average repair time for failed equipment, aiming to minimize downtime and resume normal operations quickly.

Determine average operational time before equipment failure to enhance machinery longevity and reduce breakdowns.

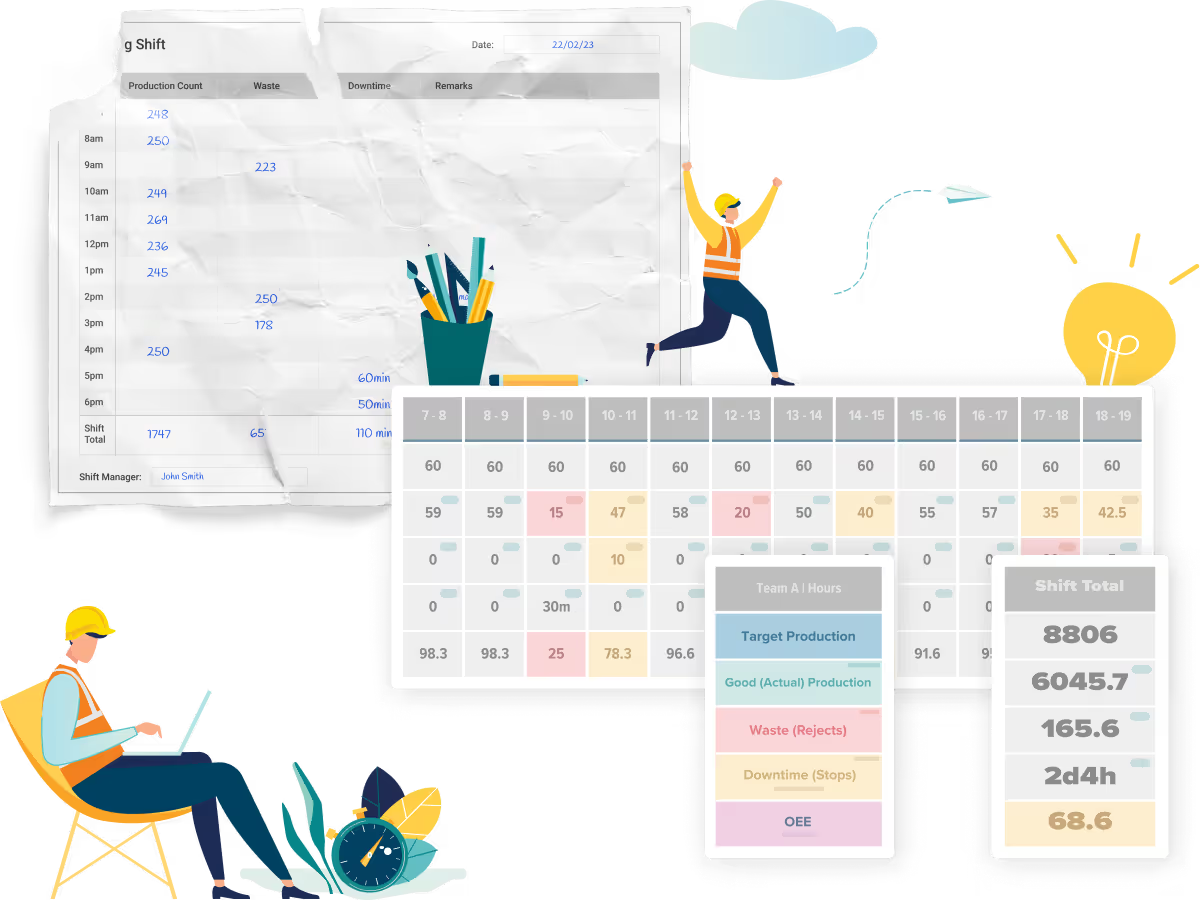

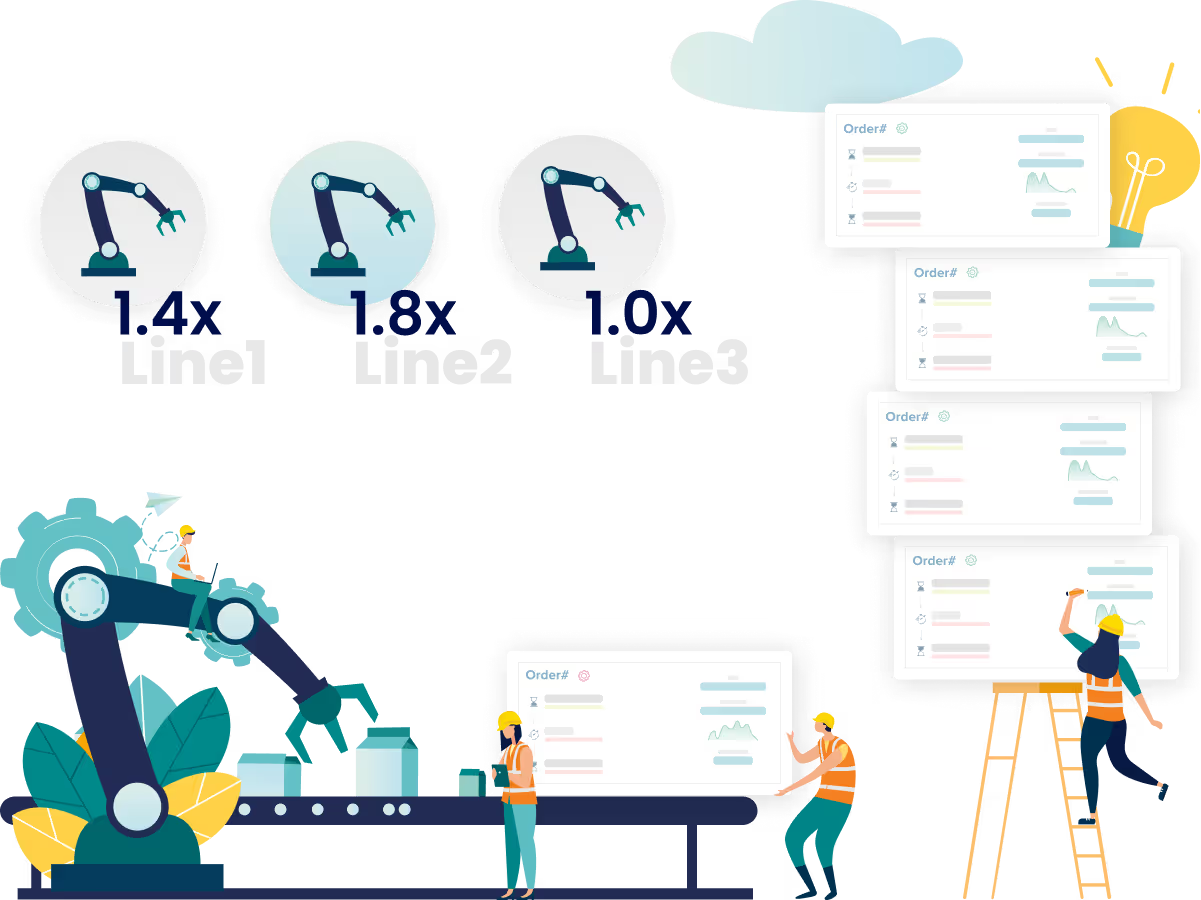

Leverage advanced scheduling and resource allocation for optimized production, enabling real-time monitoring and control of work orders from start to finish.

Simplify scheduling with historical data, making data-driven decisions based on past performance and resource availability.

Choose from Agile Board, Gantt Style, Spreadsheet View, and Daily/Weekly/Monthly Calendar Styles for convenience.

Utilize suggested schedules to complete work orders on or before the predicted time, increasing efficiency.

Integrate with ERP systems, import work orders in CSV, or create them on-the-fly within the platform for streamlined operations.

Streamline maintenance planning and scheduling with an intuitive solution to keep production running smoothly, minimize downtime, and enhance overall efficiency through well-organized maintenance plans.

Use a visual tool to plan, schedule, and track maintenance activities, streamlining efforts, improving communication, and reducing downtime.

Visualize planned maintenance with weekly/monthly Gantt and Calendar Style displays.

Save time by scheduling recurring patterns for routine maintenance tasks.

Establish SOPs for breakdown maintenance of equipment, machinery, and facilities.

Gain a competitive edge with real-time, automated production reports from Kypeco, enabling informed and effective decision-making based on accurate data.

Generate actionable, data-driven reports regularly for valuable insights on key metrics, trends, and progress tracking.

Access daily, weekly, quality control, and other production reports for informed decision-making.

Get monthly production, maintenance, and failure reasons reports for strategic planning and optimization.

Review annual performance, equipment utilization, cost and loss reports for budgeting and improvement planning.

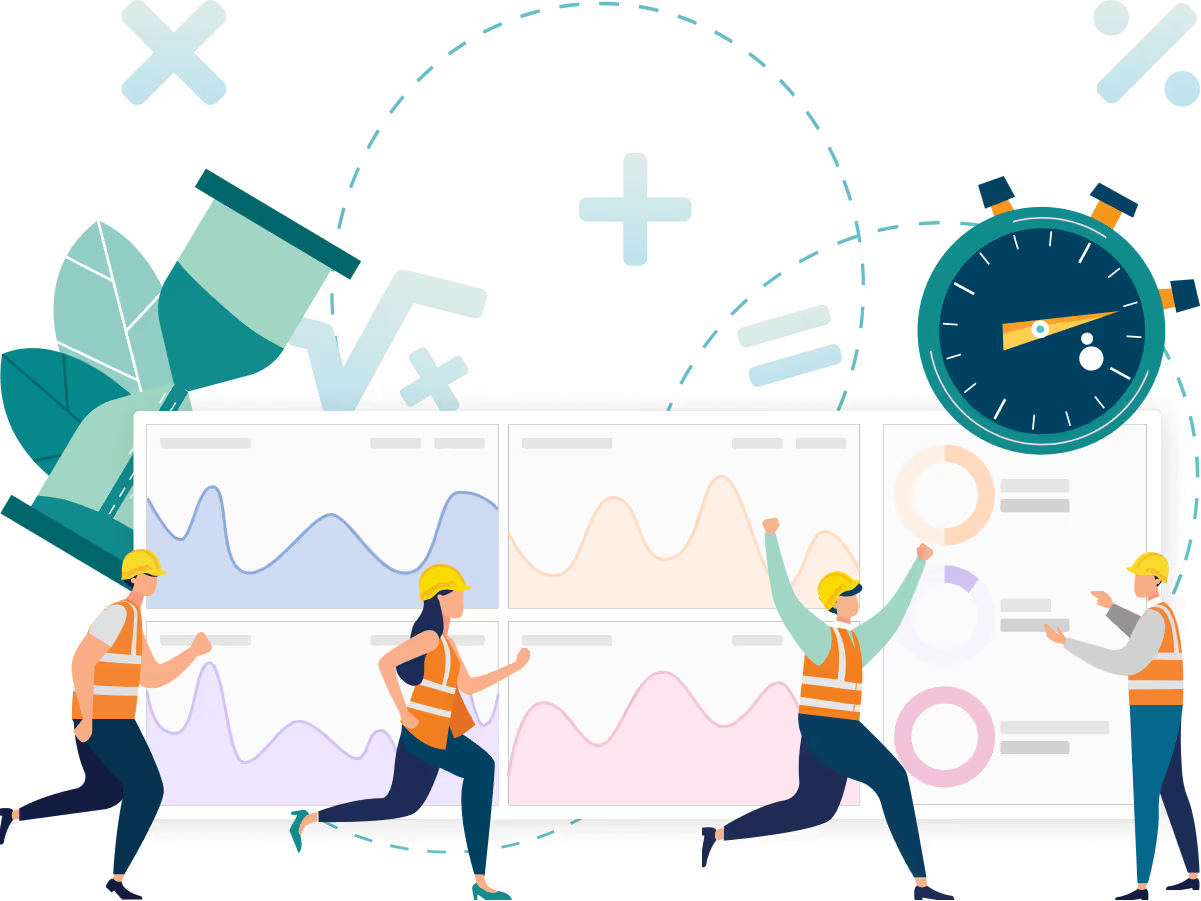

Leverage critical data for better analysis and decision-making, unlocking valuable insights into operations, enhancing efficiency, and fueling growth.

Centralize insights for improved collaboration, breaking down barriers between teams and enabling informed decision-making.

Transform collaboration with our smart solution, replacing paper-based tasks with efficient digital processes.

Centralized dashboards for all teams, promoting transparency and data-driven insights across the organization.

Implement Agile Transformation and leverage continuous feedback for ongoing improvement and operational excellence.

Access critical data for improved analysis and decision-making, gaining insights to optimize operations, enhance efficiency, and drive growth in your business.

Harness data-driven insights to make informed decisions, optimize schedules, reduce downtime, and improve product quality.

Determine root causes of production failures, enabling proactive measures to prevent future disruptions.

Detect trends and patterns in production processes for better strategic planning and optimization.

Identify cost-reduction opportunities and refine production processes to minimize waste and loss for increased profitability.

Customize Kypeco to fit your business needs, minimize training time with user-friendly interfaces, and update terminology for seamless system integration.

Configure multiple sites and production lines effortlessly with Kypeco's advanced panel, allowing seamless customization of industrial processes.

Monitor PAQO KPI metrics, identifying deviations from benchmarks to maintain optimal performance.

Easily set up branding and language localization for a personalized experience.

Adapt SKU properties, failure reasons, and assets to align with your unique business requirements.

120+

Kypeco empowers businesses with instant access to critical information, driving better decision-making and improved operational efficiency.

Kypeco's robust data validation ensures reliable analysis, enabling informed decisions and optimal business performance.

Kypeco eliminates data silos by integrating multiple systems, fostering collaboration and unlocking valuable insights across departments.

Kypeco's data lineage tracking ensures data accuracy, simplifies error identification, and supports regulatory compliance.

Efficiency is enhanced by identifying and addressing bottlenecks with Kypeco, ensuring smooth and optimized manufacturing processes.

Businesses can swiftly adapt to changing demand using Kypeco, maintaining optimal production levels and ensuring customer satisfaction.

Kypeco's advanced analytics and optimization tools enable manufacturers to maximize resource utilization and minimize production costs, driving profitability.

Real-time insights provided by Kypeco help manufacturers identify and resolve production bottlenecks, fostering continuous improvement and operational excellence.

Kypeco streamlines maintenance processes, reducing downtime and enhancing equipment performance for increased productivity.

Kypeco's real-time monitoring helps spot bottlenecks, enabling timely resolution and improved manufacturing efficiency.

Kypeco identifies sources of waste, helping businesses implement corrective measures to minimize scrap and boost resource utilization.

Kypeco's comprehensive tracking capabilities provide insights into production costs, enabling data-driven decision-making and cost optimization.

Kypeco's modern SaaS MES solution fosters a cutting-edge work environment, giving businesses a competitive edge in the industry.

Kypeco's advanced capabilities appeal to skilled professionals, helping companies recruit top talent and drive innovation.

Kypeco fosters employee satisfaction and helps retain valuable talent by streamlining operations and promoting a growth-oriented culture.

Kypeco's analytics facilitate the detection of bottlenecks in talent management, enabling companies to address issues and optimize their workforce strategy.

Kypeco unifies data and systems, promoting seamless communication and cooperation between departments.

Kypeco's automation capabilities minimize manual tasks, decreasing labor costs and increasing overall efficiency.

Kypeco delivers comprehensive cost-tracking insights, empowering businesses to optimize expenses and improve profitability.

Kypeco provides real-time data and analytics, enabling faster, data-driven decisions and increased agility in the face of changing market conditions.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for your manufacturing industry optimize your production processes, reduce downtime, and increase efficiency, providing a competitive edge for your business.

Contact us to learn how we can benefit your manufacturing operations.