Maximize uptime with our Maintenance Planner for Smart Manufacturing, proactively tackle machine downtimes, and create maintenance tasks and SOPs to optimize Shopfloor performance and Overall Equipment Effectiveness (OEE)

Use Modern Maintenance Planner to Predict the machine failure using Trends Analysis. Let AI suggest when to plan the next maintenance.

Analyze data to optimize maintenance strategies effectively and improve overall availability.

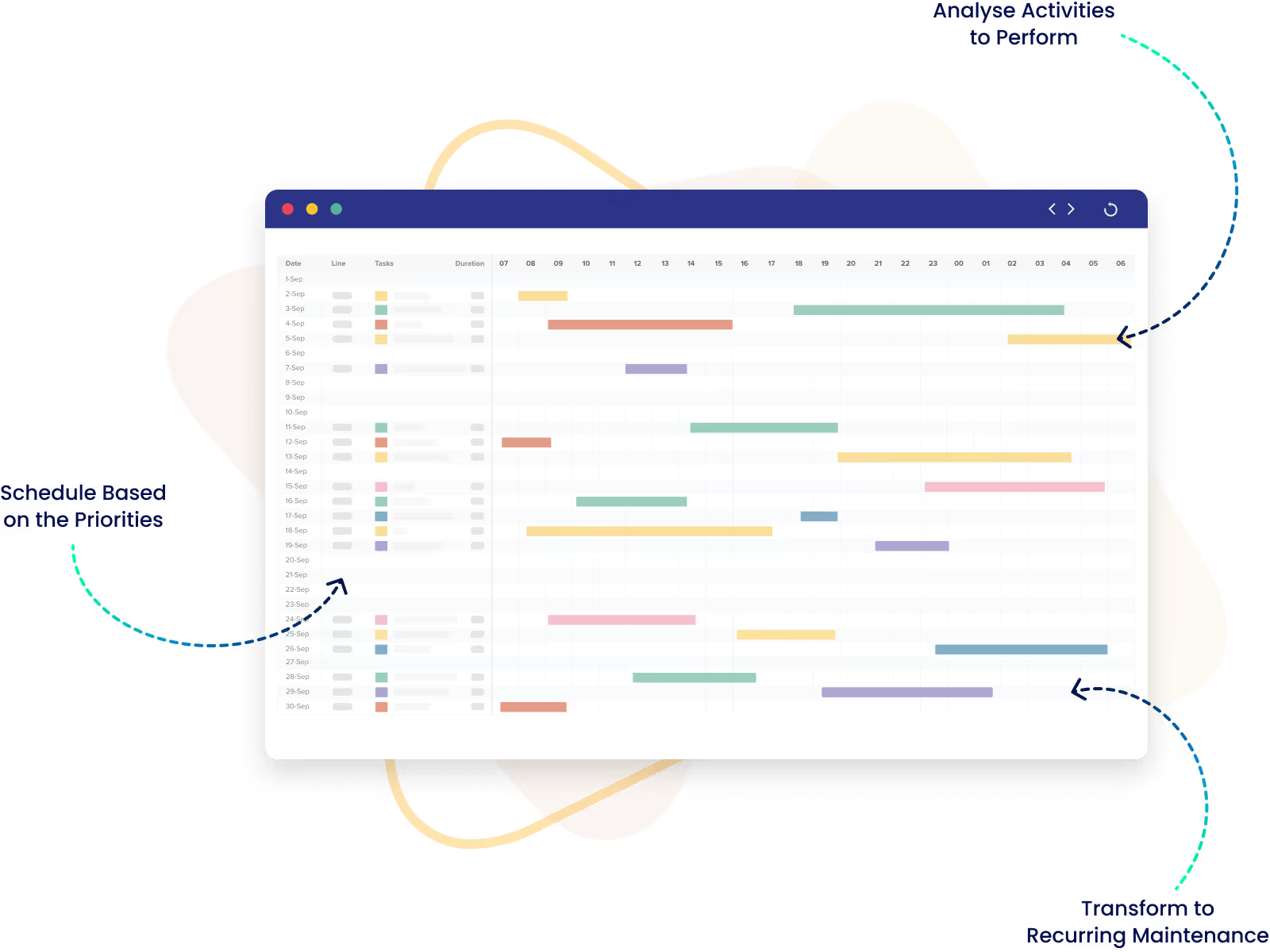

Efficiently schedule maintenance and maximize asset utilization using Gantt visualization.

Keep your machines and equipment running at their best and well-oiled!

Identify potential issues on production lines before they lead to costly downtime.

Schedule maintenance proactively with predictive analytics and machine learning to minimize downtime and reduce costs.

Optimize maintenance resources with Kypeco and advanced planning to improve efficiency and reduce lead times.

Monitor maintenance performance in real-time with customized reports and dashboards to drive asset utilization.

Outline all the maintenance activities that need to be performed, including scheduled and unscheduled.

Categorize activities based on their level of criticality to ensure that most important tasks are completed first.

Ensure that resources are being utilized optimally and activities are contributing to the overall efficiency operations.

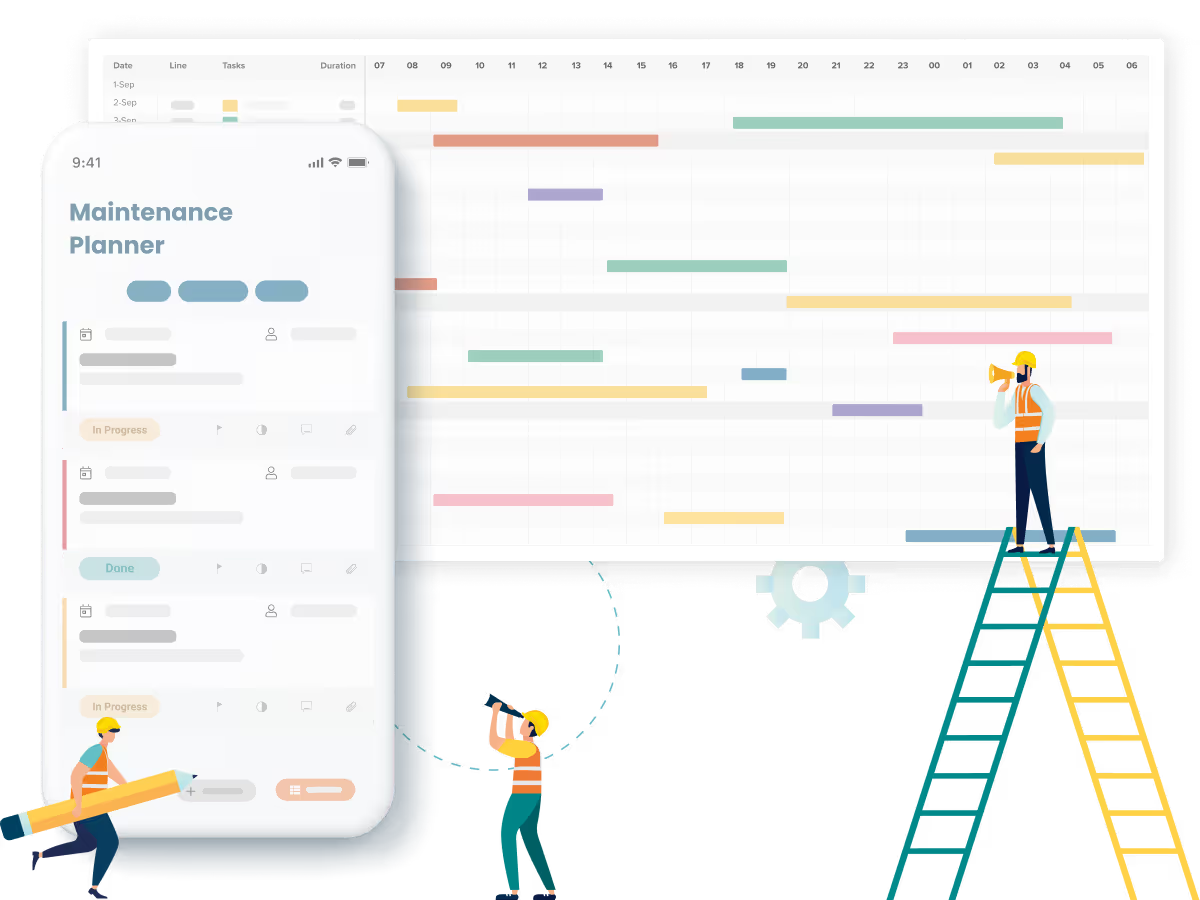

Organize Equipment Maintenance with Planner: Maximize Uptime and Minimize Downtime!

Boost efficiency, extend equipment life, and reduce downtime with our innovative Asset and Machine Maintenance Planner tailored for smart manufacturing.

Ready to maximize asset performance? Discover our Asset & Machine Maintenance Planner today!

Transition from reactive to proactive maintenance, leveraging predictive analytics to identify potential issues before they lead to costly downtime.

Efficiently schedule maintenance tasks, minimizing disruptions and maximizing asset utilization.

Analyze data to optimize maintenance strategies and enhance overall productivity.

Integrate with existing systems for seamless data flow and holistic asset management.

Tailor the solution to fit your specific industry and facility requirements, ensuring maximum value.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our smart maintenance planning solution streamlines your maintenance processes, reduces downtime, and increases equipment uptime. Say goodbye to unplanned downtime and hello to optimized equipment uptime.

Contact us to learn how it can benefit your manufacturing operations.