Manual processes, paperwork, and siloed data create major pain points for Electronics Equipment Manufacturing. Low OEE and technical debt limit growth and profitability. The workforce struggles to focus on manufacturing in the absence of digital automation. Kypeco MES can transform these challenges.

Kypeco MES provides a comprehensive solution that digitalizes the manufacturing process, improves OEE, and reduces downtime. Its automated reporting system eliminates paperwork and manual report creation. With the use of ML and AI, Kypeco MES improves quality, reducing technical debt and achieving progress towards Industry 4.0. Kypeco MES's modern software and attractive features attract younger workers, streamlining operations and bringing electronics equipment manufacturing up to Smart Industry Readiness.

Take your operations to the next level by digitalizing your workflows and automating tedious tasks. Say goodbye to paper-based systems and hello to a more optimized, efficient future with our MES smart apps.

The future of manufacturing is here, and it's all about innovation and efficiency. Stay ahead with new MES technology.

Cloud and industrial tech can unlock new levels of efficiency and productivity, keeping manufacturers ahead of the competition.

Continuously improve production processes through regular evaluation, adopting best modern MES practices.

With our MES enhance forecasting accuracy, minimize downtime, and uncover new opportunities for growth and efficiency.

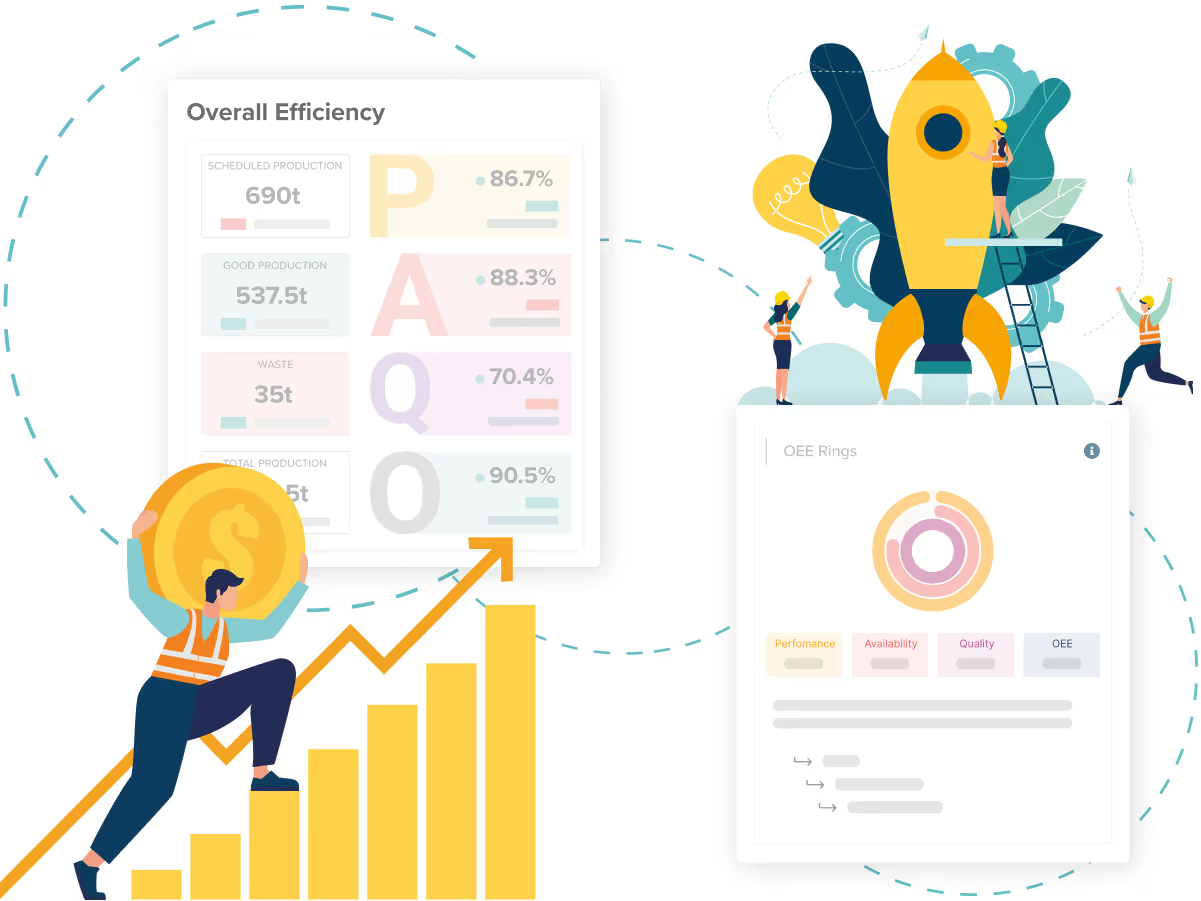

To succeed in today's business world, it's essential to maximize efficiency and productivity. By improving performance, availability, and quality, you can stay ahead of the competition and you can do it with our digital MES.

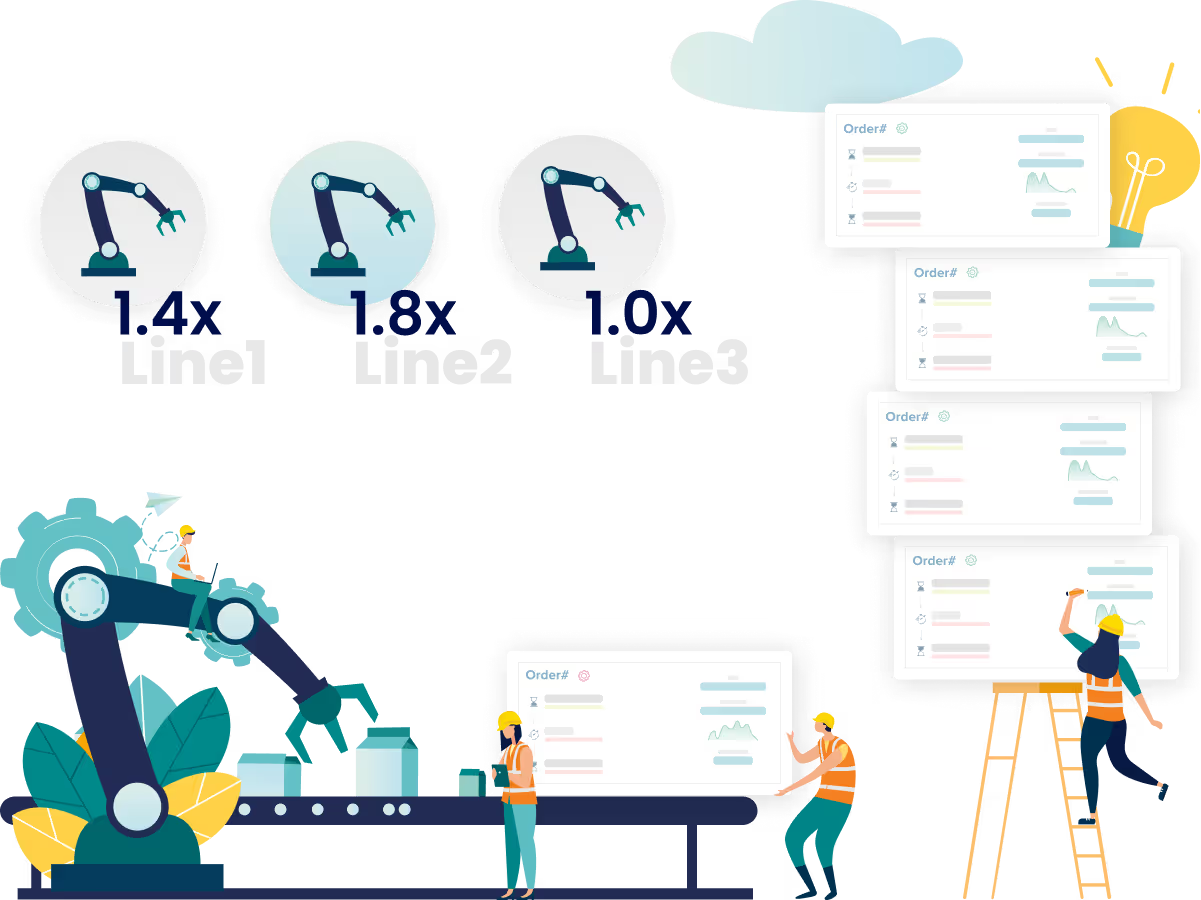

Better modern MES line efficiency monitoring can respond quickly to changing market conditions.

Instant access to critical performance metrics, enabling timely interventions with MES production dashboards.

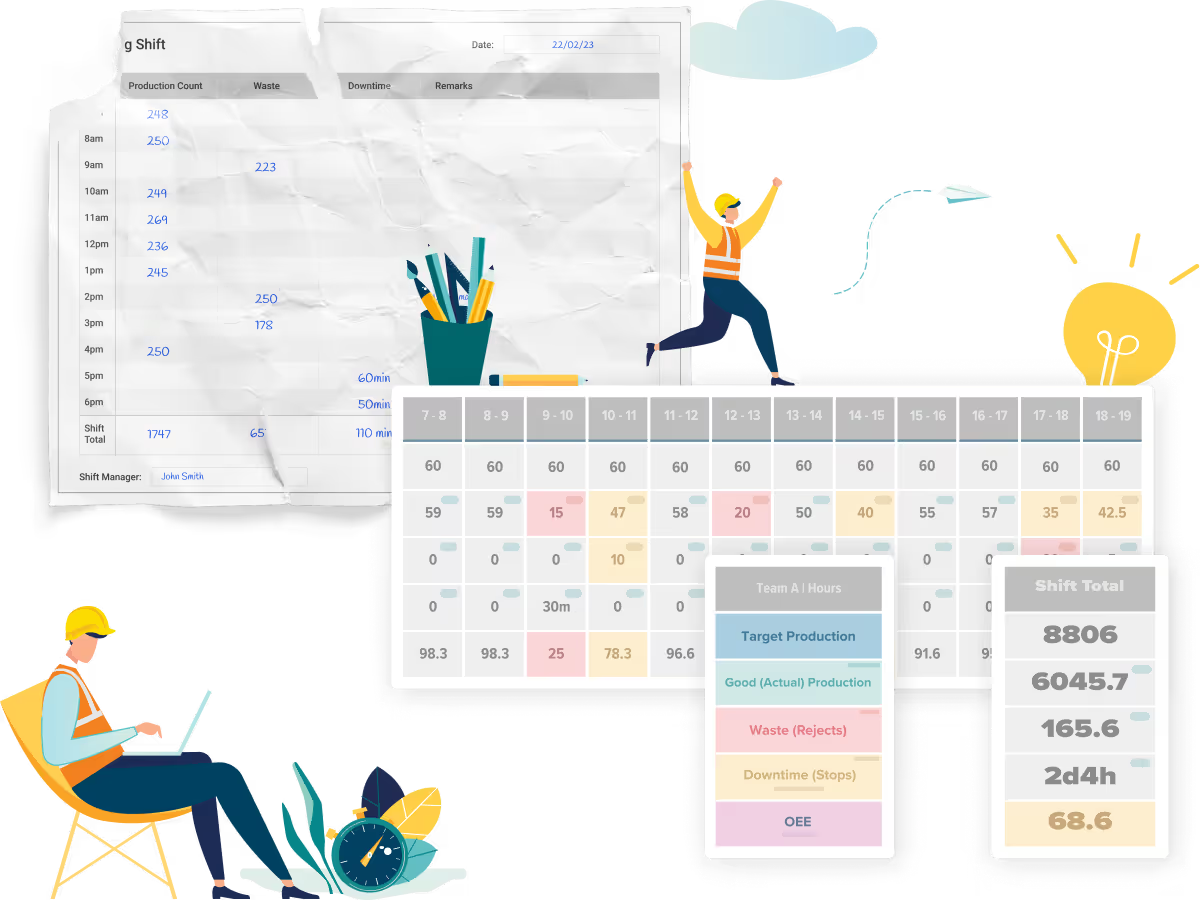

Visualize workloads, balance tasks, and optimize resource allocation for maximum productivity with MES pacing boards.

Reduce costs associated with equipment downtime and repair with our digital failure reasons dashboard.

To attract younger workers, manufacturers need to embrace next-gen MES tech and ditch paper-based processes. This can lead to improved efficiency, productivity, and employee satisfaction with digital manufacturing.

Say goodbye to paper and hello to a more digital, sustainable and efficient future. Embrace the benefits of going paperless in digital manufacturing.

Younger workers value diversity in the workplace, Modern MES creates a diverse digital manufacturing culture.

Stay ahead in manufacturing with a proactive outlook. Embrace innovation, automation, and digital transformation with our modern MES platform.

Mobile accessibility for a younger workforce. empowering them to eliminate frustrations caused by paperwork.

Elevate asset management with a dedicated assistant. Unlock MTBF, MTTR, and MTTF insights for data-driven maintenance. Maximize performance with our manufacturing execution system.

Maximize operational efficiency and reduce downtime by leveraging powerful MES asset management metrics for informed decision-making.

Measure downtime frequency with Mean Time Between Failures to enhance maintenance planning and minimize disruptions.

Minimize equipment downtime with our MES and MTTR metrics, enabling swift repairs and maximizing operational uptime.

Identify the root causes of equipment failures and implement preventive measures to minimize downtime with our MES.

Optimize work order management through a built-in smart scheduler that harnesses the power of machine learning and AI, enabling seamless task allocation with our digital MES platform in electronics equipments manufacturing industry.

Data-driven work order scheduling helps in reducing the frequency of equipment breakdowns, improving overall growth with digital transformation.

Achieve smooth work order management with our flexible digital MES visualization options, optimizing resource utilization.

Update work order scheduling effortlessly using our advanced algorithms and digital MES platform, maximizing efficiency.

Connect work order management with our digital platform, update processes and enhance efficiency.

Make maintenance management smooth with a user-friendly platform that empowers you to effortlessly plan, schedule, and coordinate tasks for seamless operations, optimal efficiency, and reduced disruptions with digital manufacturing.

With our MES, achieve visual clarity in maintenance planning, enhancing task coordination and enabling seamless workflow for improved efficiency.

Simplify maintenance planning with Gantt and calendar views for seamless operations with our MES.

Effortlessly manage repetitive maintenance tasks with recurring scheduling with our digital platform.

Enabling systematic response and maximizing equipment uptime with digital MES.

Experience the power of automated and live reports, say goodbye to delays and ensuring timely access to critical insights for enhanced decision-making with the help of our digital MES platform.

Embrace a paperless future, leveraging automated and live reports to upgrade operations and drive efficiency.

Updated reporting for manufacturing teams with automated and live data solutions for efficiency with our MES platform.

Drive organizational agility with paperless tools tailored for transformation leaders, accelerating results.

Track return on investment and cost savings to justify investments and identify areas for improvement with our MES.

Boost collaboration efficiency with a shared platform, offering transparent and centralized data for upgrade communication and improved team dynamics with our manufacturing execution systems in electronics equipments manufacturing industry.

Say goodbye to siloed data and embrace a unified approach, enabling seamless access and collaboration across your organization.

Drive collaboration with digital platforms that offer intuitive features and facilitate team interaction.

Eliminate the information silos and promote inclusivity by offering a solution that enables smooth data sharing.

Enable ongoing improvement and collaboration with a feedback loop that fosters open dialogue and shared insights.

With the help of our MES, unlock the true potential of your manufacturing data, fueling data-driven decisions that optimize processes and drive business success in electronics equipments manufacturing industry.

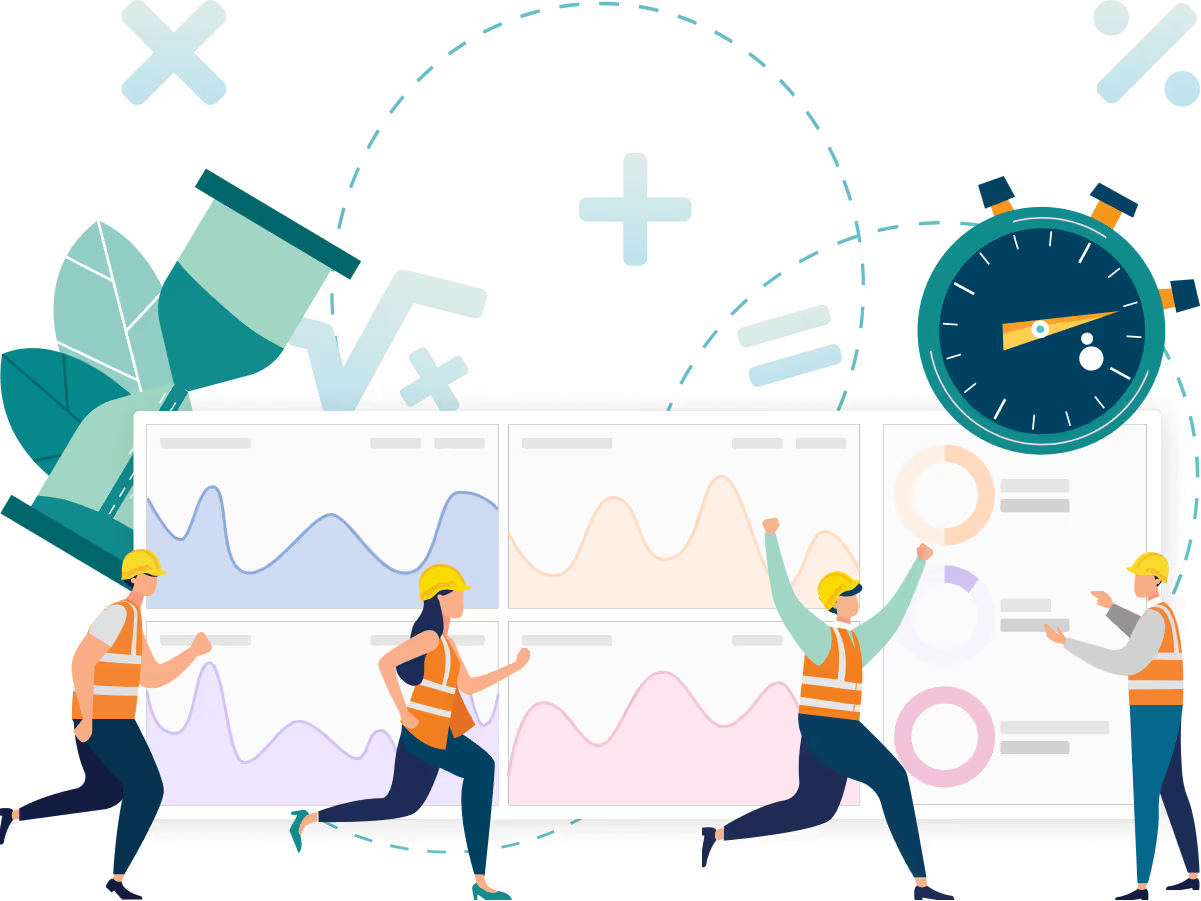

Make smarter, more informed decisions with real-time, data-driven insights into every aspect of your electronics equipment manufacturing processes.

Gain insights into root causes of quality issues, enabling effective corrective actions and product enhancements.

Analyze production data with our MES to identify patterns and trends, driving continuous improvement and growth with MES.

Implement strategies to reduce costs, minimize loss and increase profitability, leveraging data-driven insights.

Optimize efficiency and streamline operations with a white-label MES platform designed to fit your electronics equipment manufacturing industry's branding and workflow needs.

Adopt the MES platform to fit your manufacturing processes, ensuring it aligns with your unique workflows for optimized operations.

Assess performance indicators to ensure quality control, reduce defects, and meet customer expectations with digital MES.

Brand the Kypeco platform to reflect your identity and create a consistent user experience.

Effortlessly customize SKU, failure, and asset fields for more efficient workflows and easy integration with our digital MES.

120+

Our real-time alerting system notifies users of critical data changes or anomalies in real time, enabling swift actions and helping in real-time data visibility.

Kypeco's data auditing and monitoring capabilities enable organizations to maintain consistent and accurate data.

Kypeco's data virtualization capabilities enable teams to access data without copying or moving it, which helps reduce digital data silos.

Kypeco's data lineage tracking capabilities enable organizations to trace the origin and flow of data, promoting traceability.

Kypeco optimizes production planning processes to maximize efficiency and minimize waste, helping overcome inefficient production process challenges.

With the help of Kypeco, enable dynamic production planning, allowing rapid adjustments to align with changing demand scenarios.

With the help of our production scheduling capabilities optimize production schedules, reducing lead times and improving efficiency.

Kypeco's data visualization tools provide a clear and concise view of processes, enabling quick insights into bottlenecks and inefficiencies.

Kypeco's analytics capabilities enables manufacturing industries to analyze maintenance data and identify opportunities for process improvement and efficiency

Kypeco helps industries to monitor and manage shop floor operations from anywhere, identifying bottlenecks in production.

Our MES enables industries to test and optimize production processes, reducing waste & scrap caused by process inefficiencies.

Kypeco's capabilities enable organizations to forecast production costs accurately, enabling better decision-making and cost optimization.

Kypeco's branding features enable organizations to create a strong brand image and enhance competitiveness through effective brand management.

Enables industries to offer flexible work options, improving work-life balance and enhancing the attraction of a skilled workforce

Employee surveys enable organizations to gather employee feedback and identify opportunities for improvement, helping in retaining an experienced workforce.

Kypeco's process optimization capabilities enable organizations to optimize their processes, preventing bottlenecks and enhancing process efficiency.

Our MES enables organizations to create virtual workspaces for cross-departmental collaboration, enhancing collaboration.

Our knowledge-sharing platform reduces reliance on manual labor, fostering team collaboration and driving fewer costs.

Our MES enables organizations to track production costs across departments, facilitating collaboration and cost optimization.

Kypeco's predictive analytics capabilities enable organizations to predict outcomes and make informed decisions, speeding up decision-making.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the electronics equipment industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your electronics equipment manufacturing operations.