1. Embrace the Future of Manufacturing with Smart Apps and Digital Solutions

In today's rapidly evolving manufacturing industry, traditional paper-based systems are no longer sufficient to drive efficiency and stay ahead of the competition. To upgrade your automotive industry workflows and enhance operational efficiency, it is crucial to embrace digital Manufacturing Execution Systems (MES). These smart apps and digital solutions empower manufacturers to unlock the future of manufacturing. Let's explore how you can leverage these technologies to innovate and drive success.

Unlock the Future & Innovate Manufacturing

In order to stay competitive in the manufacturing industry, it is essential to adopt new technologies and processes. MES solutions serve as a gateway to the future of manufacturing by providing real-time insights and optimization opportunities. By embracing MES, manufacturers can drive innovation, improve product quality, and enhance customer satisfaction.

Adopt Cloud and Industrial Technology

Cloud computing has revolutionized the way businesses operate, and the manufacturing industry is no exception. By adopting MES cloud computing, manufacturers can experience improved performance, scalability, and data accessibility. Industrial technologies, such as the Industrial Internet of Things (IIoT), further enhance efficiency by reducing downtime and enabling predictive maintenance.

Re-evaluate Production Processes

Continuously re-evaluating production processes is vital for maintaining a competitive edge. MES solutions offer advanced analytics capabilities that allow manufacturers to collect and analyze real-time data. By leveraging this data, manufacturers can gain valuable insights into production performance, identify bottlenecks, eliminate waste, and optimize processes. This iterative approach to process improvement ensures ongoing efficiency gains.

Experiment Data-Driven Decisions

The power of data cannot be underestimated in the manufacturing industry. With MES solutions, manufacturers can collect and analyze vast amounts of data from various sources, enabling data-driven decision-making. By leveraging these insights, manufacturers can make informed choices about process optimization, resource allocation, and product development. Data-driven decisions help drive continuous improvement and fuel business growth.

2. Maximize Efficiency. Unleash Performance, Availability, and Quality

In today's business world, maximizing efficiency, optimizing performance, and ensuring high product quality are imperative for success. MES solutions empower manufacturers to achieve these goals by providing tools and features that enhance production efficiency and enable real-time monitoring and decision-making. Let's explore how MES can help you maximize efficiency in your automotive industry.

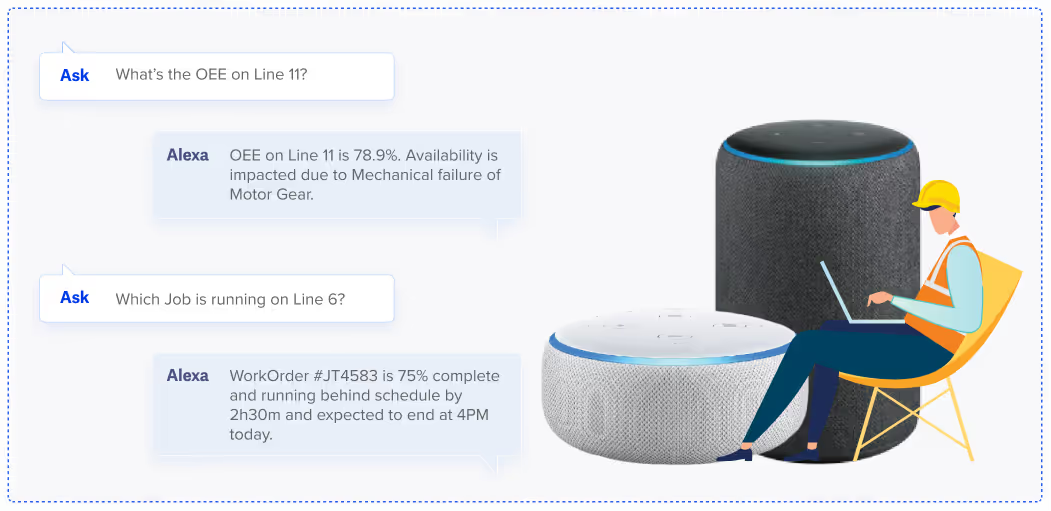

Implement Effective Line Efficiency Monitoring

Efficient line monitoring is crucial for identifying and addressing inefficiencies in real-time. MES solutions enable manufacturers to monitor line performance metrics, such as Overall Equipment Effectiveness (OEE), cycle times, and production rates. By analyzing this data, manufacturers can make informed decisions, optimize line operations, and improve productivity.

Real-time Production Line Dashboard

Reacting promptly to production issues is essential to minimize disruptions and maintain optimal output. MES solutions offer real-time production line dashboards that provide a comprehensive overview of production status, equipment performance, and quality metrics. These dashboards enable manufacturers to monitor key indicators, identify deviations, and take immediate corrective actions.

Shopfloor Production Pacing Board

Responding efficiently to changes in production demand requires effective planning and coordination. Modern production pacing boards offered by MES solutions facilitate real-time tracking of work orders, production targets, and resource allocation. These visual management tools enhance communication and enable agile decision-making, allowing manufacturers to adapt quickly and maintain a balanced production flow.

Failure Reasons Dashboard

Proactively identifying and addressing production issues is crucial to minimizing downtime and optimizing performance. MES solutions provide failure reasons dashboards that help manufacturers track and analyze the root causes of failures or defects. By identifying recurring issues, manufacturers can implement corrective actions, improve product quality, and optimize production processes.

Digital Production Monitoring System.

Start with Lean Manufacturing Production Boards.

3. Embrace NextGen Tech. Attract and Retain Millennials with Paperwork-Free Solutions

In order to attract and retain the younger workforce, it is crucial for manufacturers to embrace NextGen technologies and create a modern, dynamic workplace. By adopting the latest Manufacturing Execution Systems (MES), companies can not only streamline operations but also appeal to the tech-savvy millennials. Let's explore how adopting MES can help create a workplace that resonates with the younger workforce.

By Going Paperless with a Manufacturing Execution Systems

Traditional paperwork is not only cumbersome but also costly to manage. Adopting MES enables manufacturers to go paperless and eliminate the expenses associated with printing, storing, and managing paper documents. This transition to a digital environment not only saves costs but also reduces environmental impact.

Build for Younger Workforce

To attract and engage younger workers, it is essential to embrace modern MES technology and create a workplace that aligns with their preferences. By implementing MES, manufacturers can offer a technologically advanced work environment that encourages collaboration, innovation, and flexibility. This can include features such as digital work instructions, mobile access to data, and user-friendly interfaces.

Outlook for Manufacturing

The outlook for the manufacturing industry is promising, driven by advancements in technology, automation, and innovation. By adopting MES, manufacturers can position themselves at the forefront of this growth, demonstrating a commitment to staying up-to-date with industry trends and technologies. This proactive approach not only attracts millennials but also positions the company for long-term success.

Mobile Accessibility

Creating a digital MES workplace that is mobile-friendly, accessible, and user-friendly is vital to attracting younger workers. Millennials are accustomed to using mobile devices for various aspects of their lives, and by providing mobile access to MES systems, manufacturers can empower employees with real-time data, collaboration tools, and remote work capabilities. This flexibility and accessibility enhance productivity and engagement.

4. Enhance Asset Reliability. Your Private Assistant Offers MTBF, MTTR, MTTF Insights

Asset reliability is critical to maintaining smooth operations and minimizing downtime in the automotive industry. By leveraging advanced analytics provided by modern MES platforms, manufacturers can predict equipment failure, optimize maintenance schedules, and reduce maintenance costs. Let's explore how MES can enhance asset reliability through various metrics and insights.

Asset Performance Indicators

Monitoring the reliability, availability, and performance of assets is essential for minimizing downtime and reducing costs. MES platforms provide comprehensive asset performance indicators that enable manufacturers to track key metrics, such as asset utilization, downtime, and overall equipment effectiveness (OEE). By analyzing these indicators, manufacturers can identify areas for improvement and optimize asset performance.

Mean Time Between Failures (MTBF)

Identifying potential issues before equipment failure occurs is crucial for maintaining efficiency and productivity. MES platforms offer insights into mean time between failures (MTBF), which measures the average time a piece of equipment operates before experiencing a failure. By proactively addressing potential issues based on MTBF insights, manufacturers can implement preventive maintenance measures, reducing downtime and enhancing efficiency.

Mean Time to Repair (MTTR)

Minimizing equipment downtime is key to maximizing productivity. MES platforms provide data on mean time to repair (MTTR), which measures the average time it takes to identify and repair equipment issues. By swiftly identifying and addressing problems based on MTTR insights, manufacturers can minimize equipment downtime, increase operational efficiency, and reduce production disruptions.

Mean Time to Failure (MTTF)

Optimizing maintenance schedules is crucial for avoiding unexpected equipment failures. MES platforms offer insights into mean time to failure (MTTF), which estimates the average time a piece of equipment is expected to perform before failure. By aligning maintenance activities with MTTF data, manufacturers can implement proactive maintenance strategies, ensuring optimal equipment reliability and minimizing.

5. Optimize Work Order Management. Harness the Power of Smart Scheduler with ML and AI

Efficient work order management is crucial for optimizing productivity and reducing delays in the automotive industry. With our smart MES scheduling technology, manufacturers can leverage machine learning (ML) and artificial intelligence (AI) to automate the assignment of work orders based on factors such as skill set, availability, and priority. Let's explore how this advanced scheduling capability can drive operational efficiency.

Data-Driven Scheduling Strategies

Optimizing work order scheduling is key to improving overall equipment effectiveness and achieving higher levels of operational efficiency. With the modern MES platform, manufacturers can leverage data-driven scheduling strategies that consider various factors, such as machine capabilities, resource availability, and production targets. By analyzing real-time data and production insights, manufacturers can ensure optimal resource allocation, minimize idle time, and reduce delays.

Flexible Visualization Options

Flexible visualization options provided by the MES platform offer valuable insights into operations. Manufacturers can easily visualize work order status, timelines, and dependencies, allowing for better coordination and optimization of overall processes. With a clear overview of the entire production landscape, managers can make informed decisions, adjust schedules in real-time, and allocate resources effectively.

Effortless Scheduling

By streamlining work order management with the MES platform, manufacturers can significantly improve productivity. Scheduling tasks become effortless, as the system automates the assignment of work orders based on predefined criteria. This eliminates the need for manual intervention, reduces errors, and ensures a smooth flow of operations. With automated scheduling, manufacturers can optimize resource utilization, minimize idle time, and improve overall efficiency.

Seamless ERP & E-Commerce Integration

The integration of the MES platform with enterprise resource planning (ERP) and e-commerce systems enhances work order visibility, optimizes resources, and upgrades overall processes. Seamless data flow between these systems ensures accurate and up-to-date information, enabling manufacturers to make informed decisions. By integrating MES with ERP and e-commerce, manufacturers can align work order management with inventory levels, customer demands, and production capacities, resulting in improved efficiency and customer satisfaction.

Real-time Production Data Points.

Take the next step to digitalize your site!

Smart Manufacturing Software

Bespoke Solution for Modern Manufacturing

6. Simplify Maintenance. Plan and Schedule for Effortless Operations.

Efficient maintenance planning and scheduling are vital for reducing unplanned downtime, optimizing equipment reliability, and improving overall equipment effectiveness in the automotive industry. With the modern MES platform, manufacturers can simplify maintenance workflows, streamline scheduling processes, and enhance operational efficiency. Let's explore how MES can simplify maintenance operations.

Visualized Maintenance Planning

The MES platform simplifies maintenance planning by providing a visual interface that offers a clear overview of assets, schedules, and resources. Manufacturers can easily create maintenance plans, allocate resources, and define timelines using intuitive visualization tools. This visual representation allows for better coordination, improved resource management, and streamlined maintenance operations.

Gantt & Calendar Views

Planning and scheduling maintenance tasks become effortless with the Gantt and calendar-style views offered by the modern MES platform. These views provide a comprehensive visual representation of maintenance activities, timelines, and dependencies. Manufacturers can easily identify critical tasks, allocate resources efficiently, and ensure that maintenance activities are scheduled without causing disruptions to production.

Set Recurring Maintenance

Effortless maintenance planning is facilitated by the ability to set up recurring maintenance tasks in the MES platform. By defining predefined schedules for routine maintenance activities, manufacturers can ensure that inspections, servicing, and preventive measures are carried out at regular intervals. This proactive approach to maintenance minimizes the risk of unexpected failures, improves equipment uptime, and enhances overall operational effectiveness.

Breakdown Maintenance SOPs

Well-defined breakdown maintenance standard operating procedures (SOPs) in the automotive industry improve equipment uptime and minimize production disruptions. The MES platform enables manufacturers to establish standardized protocols and workflows for addressing unplanned equipment failures. With clear guidelines in place, maintenance teams can respond swiftly, diagnose.

7. Real-Time Analytics. Instant Reports, No More Delays, Always Available

In today's fast-paced manufacturing environment, real-time data and instant access to accurate information are crucial for making data-driven decisions. With Kypeco's modern MES platform, manufacturers can leverage real-time analytics and automated reporting to gain valuable insights and improve operational efficiency.

Eliminate Paper and Boards

Simplify operations and reduce reliance on physical documents with Kypeco's paperless MES platform. By digitizing processes, manufacturers can eliminate the need for whiteboards and physical reports, streamlining information flow and ensuring data accuracy.

For Manufacturing Operations Teams

Empower manufacturing operations teams with real-time insights and reporting capabilities offered by the innovative MES platform. By providing access to real-time data on production performance, quality metrics, and resource utilization, the platform enables teams to monitor operations, identify bottlenecks, and make data-driven decisions for process optimization.

For Business Transformation Leaders

Kypeco's MES platform serves as a valuable tool for business transformation leaders. By leveraging real-time analytics and reporting, these leaders can identify opportunities for optimization, gain insights into performance trends, and develop effective strategies for digital transformation. The platform enables them to align business goals with operational improvements and drive overall business growth.

For Financial Executives (CFO)

Accessing financial data on-demand and simplifying cost and loss financial reporting is critical for financial executives. Kypeco's modern MES platform offers CFOs a centralized system where they can access financial data in real-time, analyze costs, track losses, and generate accurate reports. This streamlines financial analysis and reporting processes, enabling faster decision-making and improved financial management.

Digital Software Tools for Industry 4.0 Factory.

Automate Manufacturing Process in the Production.

8. Foster Team Collaboration. Empower with Transparent and Centralized Data

Effective collaboration across teams is essential for driving success in the automotive industry. Kypeco's modern MES technology facilitates better team collaboration by providing transparent and centralized data, unlocking valuable insights for informed decision-making.

Break Down Data Silos

Simplify operations and reduce reliance on physical documents with Kypeco's paperless MES platform. By digitizing processes, manufacturers can eliminate the need for whiteboards and physical reports, streamlining information flow and ensuring data accuracy.

Digital Collaboration

Empower manufacturing operations teams with real-time insights and reporting capabilities offered by the innovative MES platform. By providing access to real-time data on production performance, quality metrics, and resource utilization, the platform enables teams to monitor operations, identify bottlenecks, and make data-driven decisions for process optimization.

A Solution with Inclusion

Kypeco's MES platform serves as a valuable tool for business transformation leaders. By leveraging real-time analytics and reporting, these leaders can identify opportunities for optimization, gain insights into performance trends, and develop effective strategies for digital transformation. The platform enables them to align business goals with operational improvements and drive overall business growth.

Continuous Feedback Loop

Accessing financial data on-demand and simplifying cost and loss financial reporting is critical for financial executives. Kypeco's modern MES platform offers CFOs a centralized system where they can access financial data in real-time, analyze costs, track losses, and generate accurate reports. This streamlines financial analysis and reporting processes, enabling faster decision-making and improved financial management.

9. Data-Driven Decision-Making. Unlocking Manufacturing Potential with Digital Tech.

In the modern automotive industry, harnessing the power of manufacturing data is essential for unlocking hidden patterns and insights that can drive data-informed decision-making. Kypeco's MES platform empowers manufacturers to leverage data to make smarter, more informed decisions across all aspects of their manufacturing processes. Let's explore how the MES platform enables data-driven decision-making.

Insightful Manufacturing Decision

With real-time, data-driven insights into every aspect of your automotive manufacturing processes, the MES platform equips manufacturers with the information they need to make informed decisions. By analyzing production data, quality metrics, and resource utilization, manufacturers can gain valuable insights into efficiency, identify areas for improvement, and drive operational excellence.

Root Cause Identification

The MES platform enables quick identification of the root causes of problems, allowing manufacturers to take proactive measures to prevent their reoccurrence. By analyzing data and performance indicators, manufacturers can identify underlying issues, whether it's equipment malfunctions, process inefficiencies, or quality deviations. Addressing root causes helps optimize processes, minimize disruptions, and improve overall productivity.

Production Trend Analysis

Maximizing production efficiency is a key goal for manufacturers, and trend analysis plays a vital role in achieving it. The MES platform offers tools for analyzing production trends, allowing manufacturers to identify patterns, performance trends, and opportunities for improvement. By understanding these trends, manufacturers can implement targeted strategies to optimize production, streamline workflows, and enhance overall efficiency.

Optimize Costs & Minimize Loss

With the MES platform, manufacturers gain a holistic view of production costs and losses. By analyzing data on costs, losses, and quality metrics, manufacturers can make informed decisions to drive efficiency and minimize waste. This includes optimizing resource allocation, identifying cost-saving opportunities, and implementing measures to reduce losses. The platform provides the necessary insights for strategic cost management and continuous improvement.

10. Tailor-Made Digital MES Solution. Your Branding, Locale, and Optimized Workflows

Kypeco's MES platform offers a tailor-made solution that can be personalized to fit your unique manufacturing workflows and requirements. From custom branding and language localization to optimized workflows, the platform ensures a cohesive and efficient user experience in the modern automotive industry.

Customize for Your Manufacturing Workflows

Adapt Kypeco's MES platform to align with your specific manufacturing processes and workflows. The platform is flexible and can be customized to accommodate your unique requirements, empowering you to improve efficiency, streamline operations, and drive business growth. Customization options allow you to tailor the platform to your specific needs, ensuring a seamless integration into your existing operations.

Benchmark Production KPIs & OEE

Track production Key Performance Indicators (KPIs) and Overall Equipment Effectiveness (OEE) benchmarks using the MES platform. By setting and monitoring these metrics, manufacturers can gain insights into performance, identify areas for improvement, and drive continuous improvement initiatives. Benchmarking enables you to compare your performance against industry standards and best practices, setting targets for optimization and performance excellence.

Branding & Language Localization

Customize the look and feel of Kypeco's MES platform to reflect your automotive brand identity. By incorporating your branding elements, the platform becomes a seamless extension of your company's visual identity. Additionally, language localization allows you to adapt the platform's user interface to the preferred language of your workforce, promoting ease of use and efficient communication.

Customize SKUs, Failures & Assets

Modify SKU properties, failure reasons, and assets within the MES platform to optimize operations and meet the changing demands of the automotive industry. This customization allows you to adapt the platform to your specific product lines, production requirements, and quality control processes.

Modern Manufacturing Solutions for Increased Profitability

In conclusion, upgrading your manufacturing process is a critical step towards unlocking untapped potential and achieving remarkable results. By implementing the key points discussed in this blog, you can optimize your productivity and maximize your return on investment (ROI). However, to fully leverage the power of these strategies, it is essential to have the right tools and technologies in place.

Upgrade your manufacturing process, harness the power of digital transformation, and propel your business towards unparalleled success. Contact IfElseCloud now and take the first step towards achieving optimal productivity and maximizing your ROI.

Remember, the future of manufacturing is here, and we are here to guide you on your journey to manufacturing excellence.