Digital MES Shopfloor Intelligence

Digitalize your production boards on the shopfloor with our NextGen Smart Manufacturing Solution - MES. Connect with lines and gain real-time insights, automate report creation with ML and AI.

- Integrated Production Planning: Say goodbye to siloed work order schedules. With our Digital MES Shopfloor Intelligence, you can enjoy transparent insights communicated in real-time. Gain visibility into your production schedules, resource allocation, and machine utilization, all on one platform.

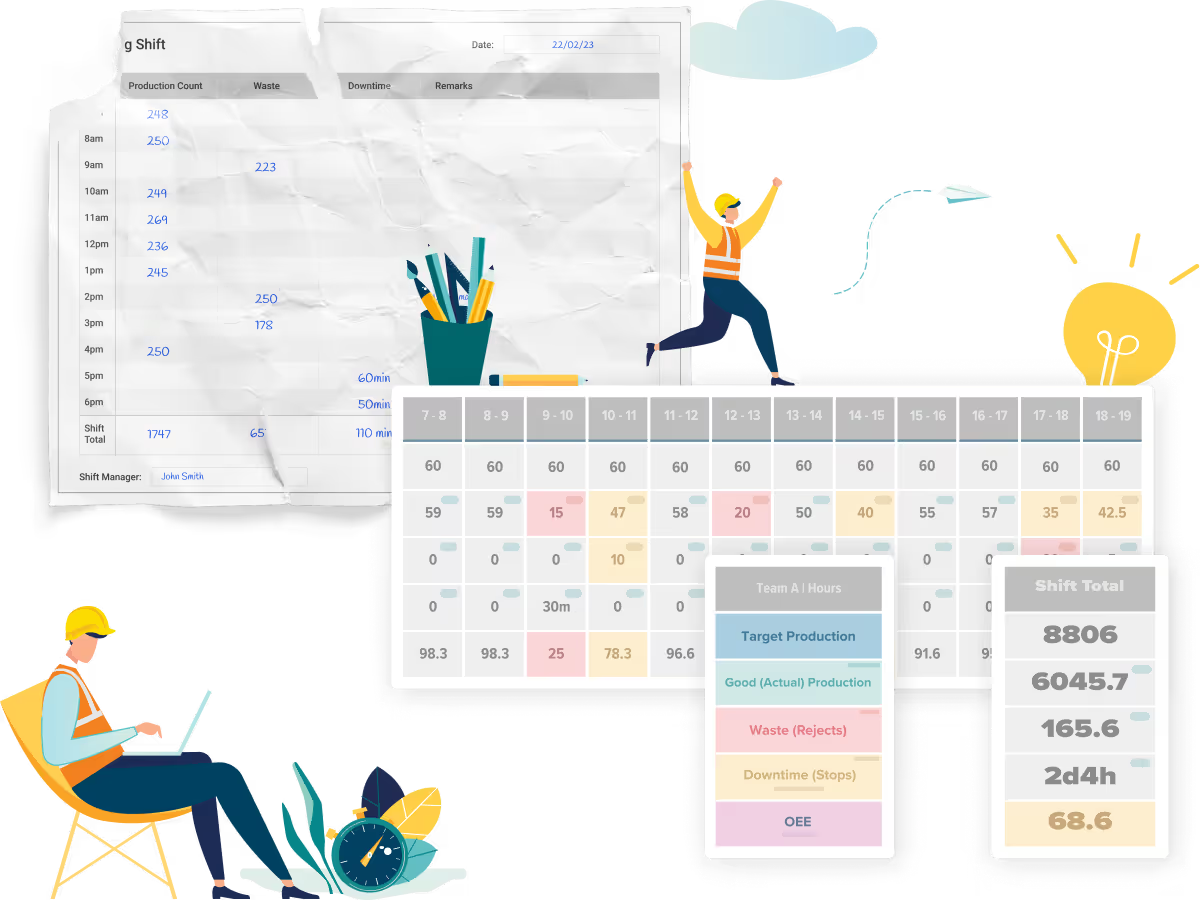

- Automated Daily Reporting: Bid farewell to manual data entry and calculation. Our intelligent system automates daily reporting, providing improved data visibility and eliminating the risk of errors. With accurate and timely reports, you can make informed decisions and drive continuous improvement.

- Real-time Shopfloor Analytics: Harness the power of real-time shopfloor analytics. By eliminating manual data entry and calculation, our platform empowers you with instant insights into key performance indicators. Monitor production metrics, identify bottlenecks, and make data-driven decisions to optimize your operations.

With Shopfloor Intelligence, you can revolutionize your manufacturing processes by digitalizing your production boards, automating reporting, and gaining real-time insights into your operations. Say hello to increased efficiency, streamlined workflows, and improved decision-making.

Visualizing Shopfloor Insights: Monitoring Platform on Videowall Enhances Meeting Efficiency.

Shopfloor Monitoring Platform

Don't waste time manually entering data into Excel when you can automate with an MES.

Improve Manufacturing Efficiency

Optimize your manufacturing efficiency with innovative solutions and smart MES technologies.

In today's fast-paced manufacturing environment, efficiency is key. Our Shopfloor Monitoring Platform empowers you to improve manufacturing efficiency by leveraging innovative solutions. Through real-time monitoring and advanced analytics, you can identify production bottlenecks, streamline processes, and optimize resource allocation. By eliminating manual data entry and adopting automated systems, you can maximize productivity and reduce operational costs.

Analyze Equipment Utilization

Maximize your equipment utilization and reduce downtime with predictive maintenance and real-time monitoring.

Equipment downtime can significantly impact production efficiency and profitability. With our Shopfloor Monitoring Platform, you can analyze equipment utilization in real-time. By leveraging predictive maintenance and IoT technologies, you can identify potential equipment failures before they occur, schedule maintenance proactively, and minimize unplanned downtime. This proactive approach to equipment management enhances productivity, extends equipment lifespan, and ensures smooth operations on the shopfloor.

Predictive Maintenance with Cloud MES

Leverage predictive maintenance to minimize downtime and prevent equipment failures by using AI and IoT technologies.

Gone are the days of reactive maintenance and costly equipment breakdowns. With our Cloud MES, you can harness the power of predictive maintenance. By combining AI algorithms and real-time data from IoT sensors, you can proactively monitor equipment health, detect anomalies, and predict potential failures.

This allows you to schedule maintenance activities during planned downtime, optimize spare parts inventory, and ultimately reduce unplanned production disruptions. With predictive maintenance, you can achieve higher equipment reliability, lower maintenance costs, and uninterrupted production.

Smart Manufacturing Practices with Smart MES

Implement smart manufacturing practices, such as digital twin and collaborative robots, to improve efficiency and reduce labor costs.

Smart manufacturing practices are revolutionizing the industry. Our smart MES enables you to implement these practices seamlessly. By leveraging digital twin technology, you can create virtual replicas of your production processes and optimize them for maximum efficiency. Collaborative robots can be integrated into your workflows to automate repetitive tasks, reduce human error, and free up your workforce for more complex operations. With smart manufacturing practices, you can achieve higher productivity, reduce labor costs, and stay ahead in a competitive market.

Lean Manufacturing Strategy

Create a lean manufacturing strategy to streamline processes and minimize waste while maximizing output and quality.

Lean manufacturing is all about eliminating waste, optimizing processes, and delivering value to customers. With our smart factory software, you can embrace a lean manufacturing strategy. By analyzing production data, identifying bottlenecks, and implementing process improvements, you can streamline your operations and reduce waste. By reducing non-value-added activities, you can improve efficiency, shorten lead times, and enhance product quality. Our platform provides the tools and insights you need to implement and sustain a lean manufacturing culture.

Continuous Improvement

Monitor performance metrics in real-time and continuously improve processes with the latest MES technologies, such as AI and ML.

Continuous improvement is the foundation of success in manufacturing. With our Shopfloor Monitoring Platform, you can monitor performance metrics in real-time and identify areas for improvement. By leveraging AI and ML technologies, you can analyze production data, detect patterns, and uncover hidden insights. This empowers you to make data-driven decisions, implement process optimizations, and drive continuous improvement. By embracing a culture of continuous improvement, you can stay ahead of the competition and achieve operational excellence.

Driving Unified Production Analytics: Digital Production Boards Transform Manufacturing Operations.

Digital Production Boards - Unified Production Analytics for Manufacturers

Access, Transparency, and Real-time - three pillars of Agility on one dashboard. A unique way of accumulating and representing data, so you never have to write Excel formulas again. Acquire data once, and let IfElseCloud do all the Maths and generate all the reports.

Digital production boards revolutionize the way manufacturers accumulate and analyze data. With a unified production analytics dashboard, you can achieve real-time access, transparency, and insights into your operations. Here's how it can benefit your manufacturing processes:

Real-Time Data Tracking

Monitor production data in real-time to gain valuable insights into your operations and optimize your processes. With a digital production board, you can track key performance indicators, such as production output, cycle times, and downtime, enabling proactive decision-making and continuous improvement.

Streamlined Data Collection

Simplify your data collection strategy with our smart factory software Data Acquisition Platform (DAP), reducing errors and saving time. Say goodbye to manual data entry and cumbersome spreadsheets. With automated data collection from various sources, such as sensors, machines, and quality control devices, you can ensure accurate and up-to-date information for analysis.

Production Traceability

Increase traceability and compliance with a digital logbook that tracks production data and ensures accuracy. With a digital production board, you can easily trace product history, including batch numbers, process parameters, and quality records. This not only enhances quality control but also enables efficient recall management and regulatory compliance.

Enhanced Collaboration

Foster collaboration between teams with a Digital Logbook that enables real-time updates and insights. With a centralized platform for data sharing and communication, cross-functional teams can work together seamlessly, accessing the same set of information. This promotes transparency, enables faster decision-making, and facilitates effective problem-solving.

By implementing digital production boards, manufacturers can transform their data accumulation and reporting processes. With real-time access to accurate data, streamlined data collection, enhanced traceability, and improved collaboration, manufacturers can drive operational excellence and stay ahead in a competitive market.

Seamless Integration, Automated Efficiency, and Process Optimization: Connecting Machines for an Enhanced Shopfloor Experience.

Connect Machines. Automate Shopfloor. Optimize Process.

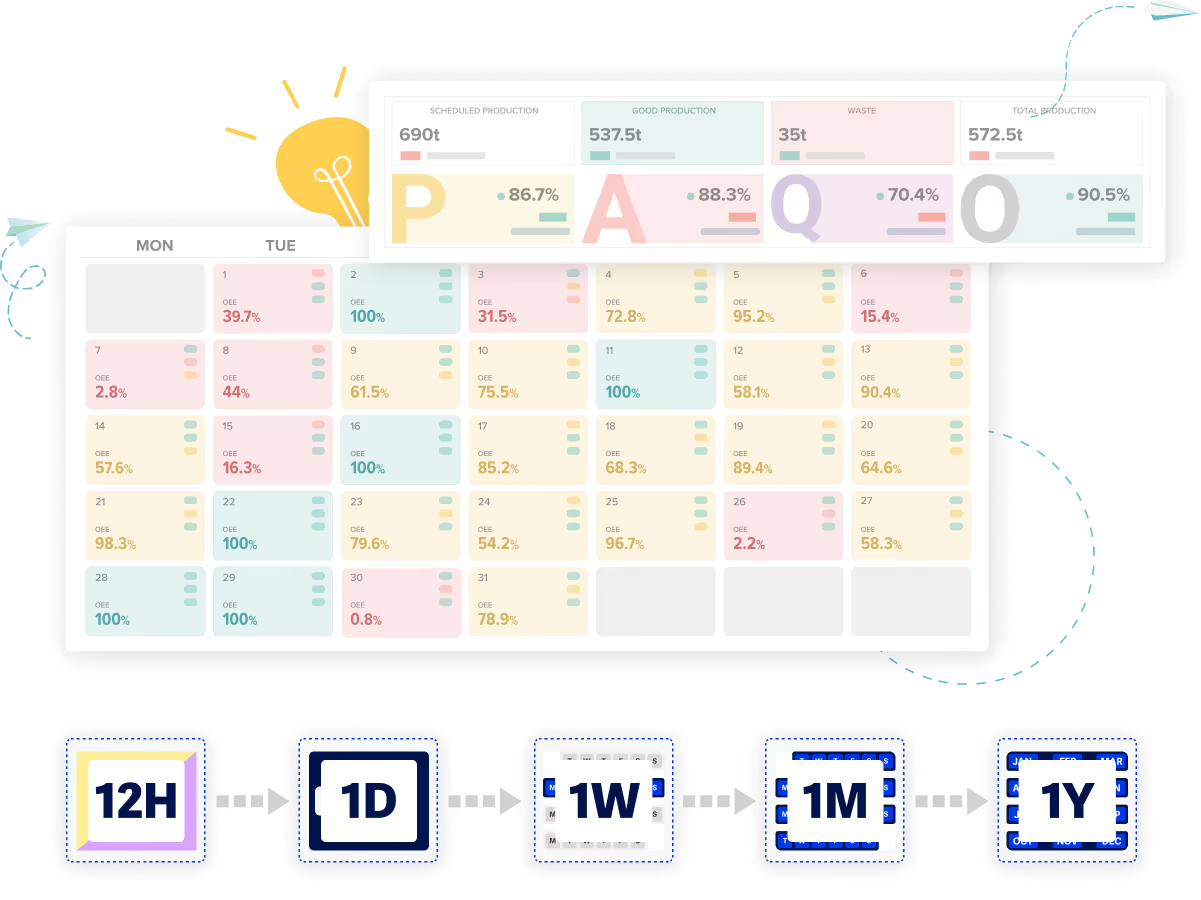

Production Calendars for Performance, Availability, Quality, and OEE Monitoring

Efficient production planning is crucial for meeting targets and maximizing productivity. With production calendars, you can gain a comprehensive view of performance, machine availability, quality metrics, and Overall Equipment Effectiveness (OEE). By visualizing this data on a single platform, you can identify patterns, make data-driven decisions, and optimize your production schedules.

Connect IIoT Devices

Streamline your data collection process and gain insights from your connected devices. The Industrial Internet of Things (IIoT) allows you to collect data from sensors, machines, and other connected devices in real-time. By capturing data from various sources, you can gain valuable insights into machine performance, energy consumption, and quality parameters. This data-driven approach enables predictive maintenance, reduces downtime, and enhances overall efficiency.

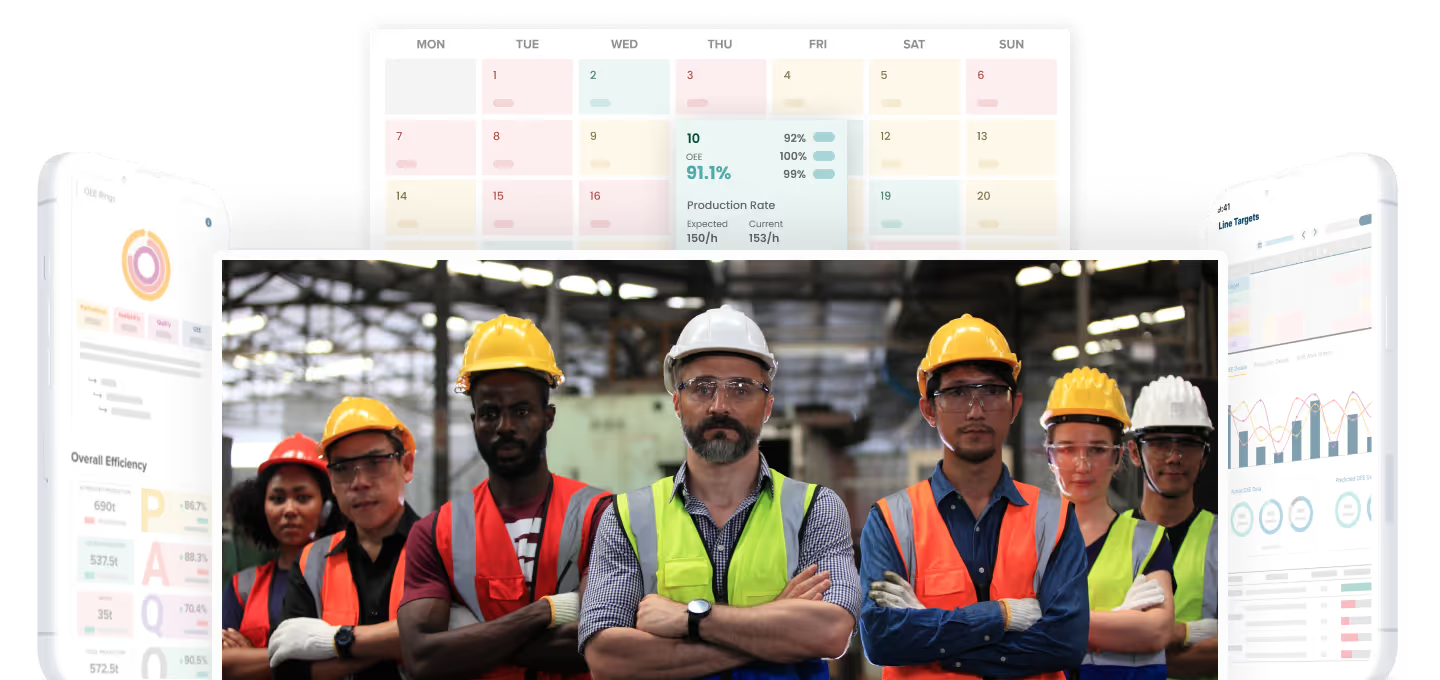

Productive Workforce

In today's digital era, the modern workforce seeks tools that are intuitive, user-friendly, and efficient. By providing your workforce with digital tools that align with their preferences, you can increase productivity and engagement. Empower your workforce with mobile apps, tablets, and user-friendly interfaces that enable them to access real-time information, collaborate seamlessly, and make informed decisions on the shopfloor.

Paperless Manufacturing

Digitalize your processes and eliminate the need for manual data entry. By replacing paper-based systems with digital tools, you can streamline data collection, reduce errors, and save valuable time. With easy data acquisition and automatic data syncing, you can eliminate duplicate data entry, improve data accuracy, and enable faster decision-making.

Efficient Process

Efficiency is the key to optimizing manufacturing operations. With easy data acquisition and streamlined processes, you can eliminate the need for manual data entry, reducing errors and saving time. By automating data collection and integrating systems, you can achieve a more efficient process flow, minimize bottlenecks, and improve overall productivity.

By connecting machines, automating shopfloor processes, and optimizing operations, manufacturers can achieve a highly efficient and productive manufacturing environment. With production calendars, IIoT connectivity, a productive workforce, paperless manufacturing, and efficient processes, manufacturers can unlock new levels of productivity and competitiveness.

Digital Logbook to Generate Production History

A digital logbook is a powerful tool that enables manufacturers to generate a comprehensive production history. With our smart factory software's digital logbook, you can capture and analyze production data at various intervals, from hourly to yearly. Here's how it can benefit your manufacturing processes:

- Real-Time Data Tracking

Monitor production data in real-time to gain valuable insights into your operations and optimize your processes. With a digital logbook, you can track key performance indicators, such as production output, cycle times, quality metrics, and downtime. By having access to real-time data, you can make informed decisions, identify areas for improvement, and take proactive actions to enhance efficiency. - Streamlined Data Collection

Simplify your data collection strategy with our smart factory software's Data Acquisition Platform (DAP), reducing errors and saving time. With automated data collection and integration with various data sources, such as sensors, machines, and quality control devices, you can eliminate manual data entry, ensuring accurate and reliable production data. This streamlined data collection process enhances data integrity and allows for efficient analysis. - Production Traceability

Increase traceability and compliance with a digital logbook that tracks production data and ensures accuracy. The digital logbook captures critical information related to batch numbers, process parameters, quality records, and other essential data points. This enables you to maintain complete traceability throughout the production process, facilitating quality control, regulatory compliance, and effective recall management. - Enhanced Collaboration:

Foster collaboration between teams with a Digital Logbook that enables real-time updates and insights. With a centralized platform for data sharing, multiple teams can access the same set of information, providing transparency and facilitating effective communication. Real-time updates and insights foster collaboration, enabling teams to align their efforts, address production issues promptly, and drive continuous improvement.

By leveraging a digital logbook, manufacturers can generate a comprehensive production history that serves as a valuable resource for analysis, decision-making, and process optimization.

Shopfloor Management Solution for Industry 4.0

Production Workflow Management for Shopfloor

Shoplfoor Intelligence for Modern Production Practices

Shopfloor Monitoring Dashboard for Industry 4.0

Shopfloor Dashboards with Machine Learning and AI

Shopfloor dashboards powered by machine learning and AI bring intelligence and actionable insights to your manufacturing operations. Here's how they can revolutionize your shopfloor:

Monitor Production Targets

Track the availability of equipment and materials required to meet production targets. With a shopfloor dashboard, you can monitor the status of resources in real-time, ensuring that production targets are achieved efficiently. By having visibility into the availability of equipment, materials, and workforce, you can proactively address any bottlenecks or constraints that may hinder production.

Automated KPI Calculations

Keep your team focused on their tasks by automating KPI calculations. With a shopfloor dashboard powered by intelligent algorithms, you can automatically calculate key performance indicators (KPIs) such as OEE (Overall Equipment Effectiveness), cycle times, and downtime. By eliminating the need for manual calculations, you can save time and ensure accuracy in reporting.

Anomaly Detection

Identify anomalies using deviations from expected patterns. By leveraging machine learning and AI algorithms, a shopfloor dashboard can detect abnormalities in production data and alert operators to potential issues. Whether it's a sudden increase in downtime or a significant drop in quality metrics, anomaly detection helps you take immediate corrective actions, minimizing the impact on production.

With shopfloor dashboards enhanced by machine learning and AI, manufacturers can gain real-time visibility into their production targets, automate KPI calculations, and detect anomalies. This empowers them to make data-driven decisions, optimize production processes, and drive continuous improvement.

Do You Have a Hidden Factory?

Many manufacturers unknowingly have a "hidden factory" within their operations. This refers to untapped potential and inefficiencies that prevent manufacturers from utilizing their existing resources to their full capacity.

Here's how we can help you uncover and address your hidden factory:

- Identifying Inefficiencies

Our Shopfloor Intelligence solution enables you to analyze your production processes and identify areas of inefficiency. By conducting a thorough assessment of your shopfloor operations, we can pinpoint bottlenecks, waste, and other factors that hinder productivity and prevent you from achieving optimal performance. - Optimizing Existing Resources

Instead of investing in new equipment or additional production lines, we focus on optimizing your current resources. Our experts work closely with you to develop strategies for improving equipment utilization, streamlining workflows, and maximizing the efficiency of your existing shopfloor setup. This approach helps you make the most of your current assets and reduces the need for costly investments. - Process Streamlining

We help you streamline your production processes to eliminate unnecessary steps, reduce cycle times, and enhance overall efficiency. By analyzing your workflows and identifying opportunities for improvement, we can implement lean manufacturing principles and best practices to streamline operations, minimize waste, and improve throughput. - Continuous Improvement

Uncovering your hidden factory is just the beginning. We support you in implementing a culture of continuous improvement by providing ongoing support, monitoring performance metrics, and identifying further optimization opportunities. Through data-driven insights and real-time analytics, we enable you to continuously refine your processes and drive sustainable growth.

By addressing your hidden factory and optimizing your existing resources, you can achieve significant improvements in productivity, efficiency, and profitability without major capital investments.

Empower Your Manufacturing Journey: Accelerate Production with Shopfloor Intelligence.

Accelerate Manufacturing with Shopfloor Intelligence

In today's fast-paced manufacturing landscape, traditional whiteboards and manual processes are no longer sufficient to meet the demands of modern production. With our Shopfloor Intelligence solution, you can accelerate your manufacturing operations and unlock new levels of efficiency.

Here's how it can benefit your business:

- Transform Your Shopfloor with Digital Manufacturing

Say goodbye to manual data entry and cumbersome processes. Our Production Pacing Board seamlessly digitalizes your shopfloor data, providing accurate, real-time production insights. With instant data visibility, you can make informed decisions, identify performance trends, and take proactive actions to optimize production. - Gain Full Production Visibility

Achieve full visibility into your production processes, allowing for proactive monitoring and quick adjustments to meet targets. With our Shopfloor Intelligence solution, you can track key performance indicators, monitor equipment utilization, and measure overall equipment effectiveness (OEE) in real-time. This enables you to identify bottlenecks, address issues promptly, and drive continuous improvement. - Increase Efficiency

Identify and eliminate bottlenecks in real-time to streamline workflows and increase efficiency. Our solution provides visibility into production processes, allowing you to identify areas of waste and inefficiency. By making data-driven decisions and implementing process improvements, you can reduce cycle times, optimize resource allocation, and increase overall productivity. - Smart Software Collaboration

Foster team collaboration by providing access to crucial data for informed decision-making. With our Shopfloor Intelligence solution, teams can collaborate seamlessly, share insights, and align their efforts towards common production goals. By breaking down silos and enabling cross-functional collaboration, you can drive greater efficiency and productivity. - Scale Your Operations

Easily adapt and scale your operations as business needs evolve with our flexible solution. Whether you're expanding production lines, launching new products, or entering new markets, our Shopfloor Intelligence solution provides the scalability and agility to support your growth. With its modular architecture and customizable features, it can be tailored to meet your specific manufacturing requirements.

By embracing Shopfloor Intelligence, you can eliminate outdated manual systems, gain instant data visibility, and improve production control. Make smarter decisions, optimize your operations, and accelerate your manufacturing with our advanced solution.

Conclusion

In conclusion, the implementation of Shopfloor Intelligence is a game-changer for manufacturers seeking to modernize their operations, increase productivity, and drive growth. By eliminating outdated whiteboards and paper-based systems, embracing real-time data visibility, and leveraging advanced analytics, manufacturers can make smarter decisions, improve production control, and accelerate their manufacturing processes.

At IfElseCloud, we offer a comprehensive Digital Manufacturing Solution that includes features such as production boards, work order management, maintenance planning, shopfloor intelligence, and reporting and insights. Our solution integrates seamlessly with IIoT, SCADA, OPCUA, ERP, and other on-prem systems, providing a unified platform for data-driven decision-making.

Transform your manufacturing operations, streamline processes, and achieve operational excellence with our Shopfloor Intelligence solution. Experience the power of digital transformation and take your manufacturing to new heights.

Contact us today to learn more about how IfElseCloud can help you optimize your shopfloor, increase productivity, and drive success in the digital era.