Real-Time Overall Equipment Effectiveness(OEE) Digital Monitoring

When it comes to assessing manufacturing performance, Overall Equipment Effectiveness (OEE) takes the center stage. This key performance indicator provides a comprehensive view of how effectively your equipment is being utilized. By calculating OEE, you can measure the productivity of your shopfloor and identify areas for improvement. The best part? Our intuitive dashboards make it easy for line operators to understand and interpret the data, facilitating informed decision-making.

Maximize Shopfloor Productivity

With real-time OEE monitoring, you can optimize performance and crush downtime. By keeping a close eye on OEE metrics, you can proactively identify and address bottlenecks, minimize unplanned downtimes, and monitor trends to improve overall uptime. This results in enhanced shopfloor productivity and increased manufacturing efficiency.

Real-Time Site-Wide Analytics

Gone are the days of manually collecting and analyzing data from various sources. With a comprehensive OEE monitoring solution, you gain a bird's-eye view of your factory's operations, centralized and in real-time. This enables you to monitor the performance of individual machines, production lines, and even the entire facility.

By having access to real-time site-wide analytics, you can make data-driven decisions promptly, optimize resource allocation, and drive continuous improvement.

Monitor Machine Availability

Unplanned downtimes can significantly impact production schedules and output. By monitoring machine availability in real-time, you can eliminate unexpected disruptions and minimize productivity losses. The ability to track machine performance and analyze availability trends empowers you to identify recurring issues, plan maintenance activities proactively, and ensure optimal utilization of your equipment.

Big Data with Machine Learning

Integrated data science capabilities take OEE monitoring to the next level. By leveraging machine learning algorithms and advanced analytics, you gain deeper insights into your manufacturing processes.

This includes detecting patterns, uncovering hidden trends, and making accurate predictions. By harnessing the power of big data, you can optimize your operations and drive continuous improvement initiatives.

Modern MES for Equipment Effectiveness (OEE)

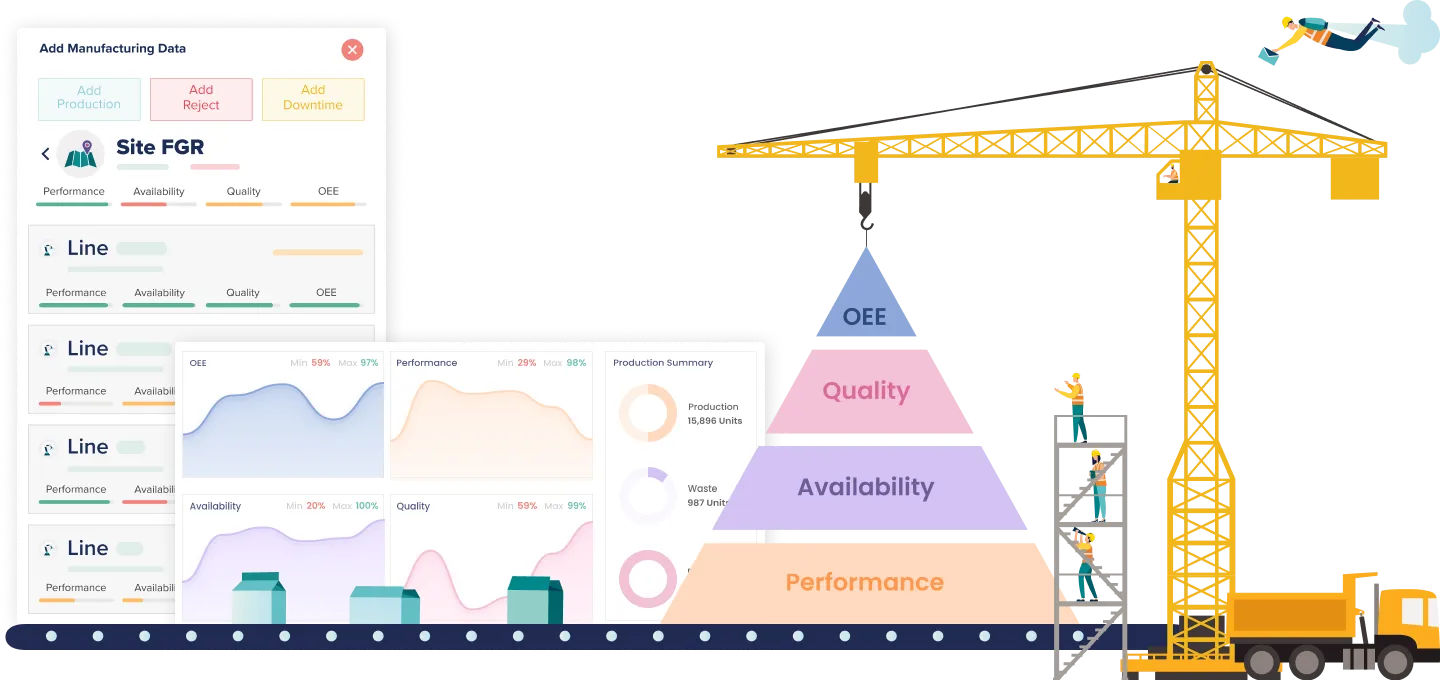

Performance

Performance is a crucial component of OEE. It accounts for situations where the process is running slower than its theoretical top speed, encompassing both small stops and slow cycles. By monitoring performance metrics, you can identify operational inefficiencies and take corrective actions to improve overall performance.

Availability

Machine availability refers to the time when the machine is not running, whether planned or unplanned. By tracking availability metrics, you can effectively manage downtime, plan maintenance activities, and ensure maximum equipment uptime. This helps you maintain a smooth production flow and optimize resource utilization.

Quality

Ensuring product quality is essential for customer satisfaction and business success. Quality-related issues can lead to waste, rework, and increased costs. By monitoring quality metrics, you can identify deviations from expected quality standards, implement corrective measures, and minimize defects. This ultimately leads to improved product quality and customer satisfaction.

Overall Equipment Effectiveness (OEE)

OEE is a comprehensive metric that considers the factors of performance, availability, and quality. It measures the overall equipment effectiveness and provides a holistic view of your manufacturing operations. By calculating OEE and analyzing its components, you can identify areas of improvement, implement targeted strategies, and drive continuous enhancement in your shopfloor efficiency.

“OEE = PERFORMANCE x AVAILABILITY x QUALITY”

Optimize OEE, Maximize Production: Unlocking Capacity with Effective Overall Equipment Effectiveness.

Maximize Your OEE to Maximize Your Production Capacity

Real-time OEE insights empower you to monitor performance and identify bottlenecks promptly. By analyzing the data in real-time, you can uncover hidden inefficiencies, optimize production schedules, and achieve operational excellence. With advanced analytics, you gain a deep understanding of the factors impacting performance, allowing you to make informed decisions for continuous improvement.

- Big Data Analytics on OEE

To improve overall manufacturing effectiveness, leveraging advanced analytics is crucial. By applying big data analytics to your OEE data, you can uncover valuable insights, detect patterns, and identify areas for optimization. These insights enable you to enhance your production processes, streamline operations, and achieve higher levels of efficiency. - Real-Time Insights by AI

Artificial intelligence (AI) plays a significant role in driving real-time insights and optimizing OEE. AI algorithms can process large volumes of data, identify patterns, and provide actionable insights to manufacturing professionals. By leveraging AI, you can monitor performance, identify potential issues, and take proactive measures to maximize your production capacity. - Predictive Maintenance

Unplanned equipment failures can be costly and disruptive. By implementing predictive maintenance strategies, you can proactively identify maintenance needs and reduce downtime. By analyzing real-time OEE data and utilizing machine learning algorithms, you can predict equipment failures, plan maintenance activities, and ensure optimal performance.

Unveiling Efficiency Roadblocks: Analyzing Failure Reasons for Improved Operational Performance.

Analyze Failure Reasons Affecting Efficiency

While shift-based OEE calculations provide immediate insights into performance, maximizing operational efficiency requires analyzing OEE trends over extended periods. Focusing solely on hourly data won't be sufficient. By conducting weekly, monthly, and yearly analysis, you gain a comprehensive understanding of your manufacturing operations and identify long-term improvement opportunities.

OEE Trend Analysis

Monitoring OEE trends allows you to track the efficiency of your manufacturing processes over time. By analyzing historical OEE data, you can identify patterns, recurring issues, and areas for improvement. This trend analysis provides valuable insights into your production efficiency, enabling you to make informed decisions and drive continuous optimization.

Weekly, Monthly, and Yearly OEE Reports

To gain a holistic view of your manufacturing operations, it is essential to generate OEE reports at different time intervals. These reports provide a comprehensive overview of your OEE metrics, including performance, availability, and quality. By reviewing weekly, monthly, and yearly reports, you can track progress, identify improvement opportunities, and set meaningful goals for your shopfloor efficiency.

Improve Production Processes

Armed with data-driven insights from OEE monitoring, you can optimize your production processes for enhanced efficiency. By identifying the root causes of inefficiencies, you can implement targeted process improvements, reduce waste, and streamline operations. This continuous improvement mindset empowers you to achieve higher levels of productivity and drive sustainable growth.

Ready to analyze Failure Reasons to Drive Manufacturing Performance

Maximizing overall equipment effectiveness (OEE) is crucial for manufacturers aiming to enhance their operational efficiency and stay competitive. With real-time OEE monitoring, advanced analytics, and integrated shopfloor solutions, you can gain valuable insights into your manufacturing processes. By leveraging data-driven insights, predictive maintenance, and AI-powered analytics, you can optimize performance, minimize downtime, and drive continuous improvement. Explore the power of real-time OEE monitoring and unleash the true potential of your manufacturing operations.

Remember, Our smart factory software comprehensive manufacturing solution offers a range of features, including production board, work order management, maintenance planner, shopfloor intelligence, reporting and insights, real-time insights using machine learning and AI, and seamless integration with IIoT, SCADA, OPCUA, ERP, and other on-prem systems. Contact us to learn more and take your manufacturing operations to the next level.