Advanced Manufacturing Reports for Data-Driven Insights

With the help of AI and machine learning, advanced manufacturing reports provide digital insights from all areas of manufacturing. These reports automate the generation of shift, daily, weekly, monthly, and yearly reports, saving you valuable time and effort. Say goodbye to tedious manual data entry and multiple Excel sheets. Let the power of advanced manufacturing reports revolutionize your data analysis and decision-making processes.

Automated Shopfloor Reports

Summary: Shift, daily, weekly, monthly, and yearly reports are delivered to your inbox automatically, eliminating the need for manual report creation. By automating shopfloor reports, you can focus on analyzing data and taking proactive actions to improve your manufacturing processes. Say goodbye to time-consuming report generation and welcome real-time insights.

Unified Manufacturing Platform for Reporting

Integrated insights from all areas of manufacturing are combined in one comprehensive report. Instead of sifting through multiple Excel sheets, you can access a unified report that provides a holistic view of your manufacturing operations. Save time and gain a deeper understanding of your performance by leveraging the power of a unified reporting platform.

Stunning Executive Reports to Impress!

Create visually stunning reports that captivate your audience and present data-driven insights in an engaging manner. With advanced visualization capabilities, you can transform complex data into easily understandable charts, graphs, and dashboards. Impress your stakeholders and make informed decisions based on visually appealing reports.

Streamlined Intelligence: Automated, Paperless Reports Revolutionize Data Insights in Manufacturing.

Intelligent Reports Automated. With Zero Paperwork.

Experience the power of intelligent reports generated by modern manufacturing solutions. These reports leverage embedded intelligence, AI, and machine learning to provide valuable insights, optimize manufacturing processes, and drive continuous improvement.

- Embedded Intelligence in Reports

Intelligent reports utilize embedded intelligence to analyze data and provide valuable insights. By leveraging AI and machine learning algorithms, these reports can identify patterns, trends, and anomalies in your manufacturing operations. Gain deeper insights into your processes and uncover hidden opportunities for improvement. - Data-driven Shopfloor Reports

Develop data-driven plans to achieve your manufacturing goals and stay ahead of the competition. With real-time shopfloor reports, you can monitor progress, identify bottlenecks, and optimize resources for better efficiency. Leverage the power of data analytics to drive continuous improvement and achieve operational excellence. - Real-time Production Reports

Stay informed about your production performance in real-time with advanced production reports. Monitor key metrics, track KPIs, and respond proactively to any deviations or issues. With real-time insights, you can make timely decisions and ensure optimal production outcomes. - Power of AI and ML in Reports

Unlock the power of AI and machine learning in your manufacturing reports. These advanced technologies enable predictive analytics, anomaly detection, and process optimization. Leverage AI and ML algorithms to optimize your manufacturing processes, reduce downtime, and drive continuous improvement. - Strategic Planning Reports

Create strategic plans to achieve your manufacturing goals and stay ahead of the competition. With comprehensive reports that provide insights into historical performance, industry trends, and market dynamics, you can make informed decisions and set a clear direction for your manufacturing operations. - Transformation Reports

Enable faster and more informed decision-making with real-time information and analytics. Transformation reports provide insights into the effectiveness of process improvements, technology implementations, and organizational changes. Leverage these reports to drive transformative initiatives and achieve long-term success.

Automate Failure Reasons Analysis Reports

Failure analysis is crucial for identifying root causes, improving machine performance, and minimizing downtime. Automate your failure reasons analysis reports to streamline the process and gain valuable insights into failure patterns.

Root Cause Identification

Analyze data recorded from machine performance, availability, measurement data, and human error to identify the root causes of failures. By understanding the underlying issues, you can implement targeted solutions to prevent future failures and improve overall reliability.

Big Six Reason Analysis

Categorize failure causes into three main categories: Performance, Availability, and Quality. By breaking down the most common causes of failures, you can prioritize actions and allocate resources effectively. Focus on the areas that have the highest impact on your manufacturing operations.

Risk Reduction Strategies

Implement risk reduction strategies based on the analysis of failure reasons. Improve quality control procedures, enhance training programs, and reduce material waste to mitigate risks and enhance overall performance. By proactively addressing potential issues, you can minimize downtime and improve productivity.

Continuous Improvement

Optimize production processes by identifying areas for improvement through recommended process optimization programs. Analyze failure trends, performance data, and maintenance records to uncover opportunities for efficiency gains and cost savings. Continuous improvement is key to achieving operational excellence.

Unveiling Manufacturing Trends: In-depth Analysis Reports for Strategic Decision Making.

Manufacturing Trend Analysis Reports

Stay ahead of industry trends and gain valuable insights into your manufacturing operations with trend analysis reports. By analyzing historical data, identifying patterns, and understanding market dynamics, you can make informed decisions and adapt your strategies accordingly.

- Demand Forecasting: Eliminate tedious paperwork and keep workers engaged in production by leveraging trend analysis reports to forecast demand accurately. By understanding market trends and customer preferences, you can optimize production planning and meet customer expectations.

- Identify Inefficiencies: Explore areas where production can be optimized by analyzing trends in key performance indicators (KPIs). Identify bottlenecks, process inefficiencies, and areas of improvement to streamline operations and maximize efficiency.

- Maintenance Reports: Set up proactive maintenance plans based on trend analysis reports. Identify patterns in machine performance, maintenance records, and failure rates to schedule maintenance activities effectively. By preventing unexpected breakdowns and reducing downtime, you can improve overall equipment effectiveness (OEE).

- Quality Control Reports: Identify patterns in quality control data through trend analysis reports. Analyze quality metrics, defect rates, and customer feedback to identify areas for improvement. By addressing quality issues proactively, you can enhance customer satisfaction and reduce rework or product recalls.

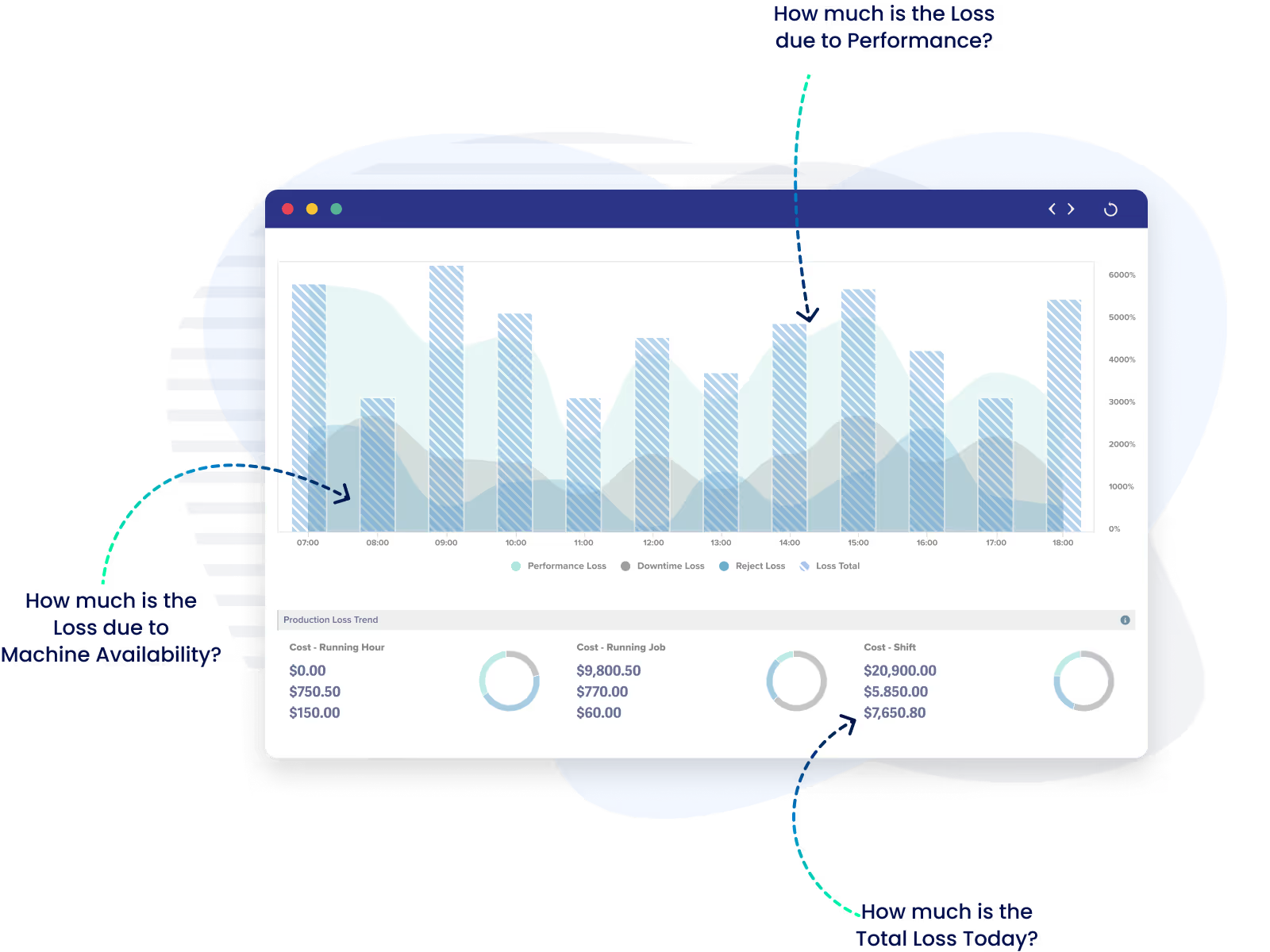

Uncovering Shopfloor Loss and Cost Insights: Analyzing Manufacturing Efficiency for Improved Performance.

Manufacturing Shopfloor Loss and Cost Analysis

Gain insights into the factors contributing to production losses and costs on the shopfloor. By analyzing data related to time, material, and value lost, you can identify inefficiencies, reduce waste, and optimize your manufacturing processes.

- Reduce Operational Losses

Analyze equipment performance, operator behavior, and process inefficiencies to identify factors contributing to production losses. By addressing these issues, you can minimize downtime, improve productivity, and reduce operational costs. - Reduce Production Waste

Analyze data on material usage, scrap rates, and waste generation to identify opportunities for waste reduction. Implement lean manufacturing principles and process optimization strategies to minimize material waste and improve resource utilization. - Reduce Machine Downtime

Take proactive measures to prevent machine downtime by analyzing maintenance records, failure data, and performance metrics. Implement predictive maintenance strategies, optimize maintenance schedules, and ensure timely repairs to maximize equipment uptime and minimize costs associated with downtime.

Daily Production Reports for Shift Meetings

Stay informed about the daily production activities and performance with comprehensive reports tailored for shift meetings. These reports provide real-time insights, allowing you to address issues promptly and make data-driven decisions.

Real-Time Shopfloor Reports

Critical data insights, including failure reasons, trends, equipment utilization, loss and cost analysis, and annual performance, are available in real-time reports. By monitoring these reports, you can identify patterns in operations, optimize resources, and drive continuous improvement.

No More Siloed Data. It's Real-Time Information.

Say goodbye to fragmented data and disconnected systems. With real-time reports, you can consolidate data from various sources, ensuring that all teams have access to up-to-date information. This promotes transparency, collaboration, and informed decision-making across the organization.

Digital Shift Handover Reports

Analyze over 50 reports offered by a digital reporting system, providing deeper insights into operations and critical data points. Customizable branding options allow you to give a personal touch to the reports, which can be easily shared with colleagues and management, leading to informed business decisions. Let the digital reporting system handle your manufacturing report generation, so you can focus on boosting production.

Export to PDF or Send via Email

Choose between eco-friendly options by exporting reports to PDF for paperless distribution or sending them via email. This flexibility allows you to share reports with stakeholders conveniently and track the delivery and receipt of crucial information.

Agile Manufacturing Software Solution for Industry 4.0

Centralized reports with ML & AI

Unified Digital Manufacturing Hub for Modern Industry Teams

Shoplfoor Intelligence for Modern Production Practices

Automated Reports: Copy Notes from Your Friends - AI & ML. Like ChatGPT.

Automate the generation of daily, weekly, monthly, and yearly reports with the power of artificial intelligence (AI) and machine learning (ML). This eliminates manual calculations and formatting, saving valuable time and resources. Read more about the automation of calculations here.

Daily Production Planning Reports

Simplify your day with customizable end-of-day reports that summarize daily activities and plan for the next shift. These reports provide a comprehensive overview of production performance, including production targets, actual output, downtime, and efficiency metrics.

Weekly Production Reports

Stay on top of your week with insightful weekly reports that provide valuable insights into your operations. Track key performance indicators, analyze trends, and compare performance against targets. Use these reports to identify areas for improvement and make data-driven decisions to drive operational excellence.

Monthly Analytics Reports

Evaluate performance and identify trends with customizable monthly reports that provide a comprehensive overview of your operations. Analyze production data, quality metrics, maintenance records, and cost information to gain valuable insights into your manufacturing processes. Use these insights to drive continuous improvement and optimize your operations.

Yearly Manufacturing Project Reports

Plan for the future with high-level yearly reports that enable you to evaluate your performance over the course of a year and set goals for the next. These reports provide a holistic view of your manufacturing projects, highlighting achievements, challenges, and opportunities for growth. Use these reports to strategize and align your operations with long-term objectives.

Transforming Data into Art: Captivating and Informative Production Reports that Inspire Your Team

Visually Stunning Production Reports Your Team Will Be Eager to Read

Say goodbye to manual report generation and embrace AI-powered reports that are visually appealing and engaging. These reports not only provide valuable insights but also captivate your audience, making them eager to dive into the data and drive meaningful discussions.

Automated Manufacturing Reports

Our digital factory software generates industry-specific, standardized reports with unmatched precision and accuracy. These reports offer reliable and detailed insights into production performance, quality metrics, equipment utilization, and other key areas. Make informed decisions and track progress effortlessly with automated manufacturing reports.

Smart Analytics with Machine Learning and AI

Leverage the power of machine learning and AI to gain real-time insights into your manufacturing operations. Smart analytics enable you to identify trends, detect anomalies, and predict future outcomes. Make data-driven decisions with confidence and optimize your manufacturing processes for improved efficiency and productivity.

One-Click Reports

Access reports instantly with a single click, eliminating the need for manual calculations and document formatting. Save time and effort by automating the report generation process, allowing you to focus on analyzing the insights and taking action.

Customizable Reports

Tailor your reports to meet specific business needs and preferences. Our advanced factory software offers customizable reporting options, allowing you to choose the metrics, visualizations, and formats that best align with your requirements. Create reports that deliver the information you need in a format that suits your team's preferences. See how you can configure the MES for your bespoke manufacturing environment.

Beautiful Production Reports

Our user-friendly interface and visually appealing reports make it easy for businesses to navigate and understand their data. Present complex information in an intuitive and visually pleasing way, ensuring that your team can quickly grasp key insights and make informed decisions.

Pioneering the Future of Manufacturing: Power of Machine Learning, AI, and Big Data Analytics in Modern Manufacturing Software.

In conclusion, the power of advanced manufacturing reports and analysis cannot be overstated. With the advent of AI, ML, and smart manufacturing solutions, manufacturers can unlock valuable insights, streamline operations, and make data-driven decisions.

Automated reports generated by AI and ML algorithms eliminate the need for manual calculations and paperwork, saving time and improving accuracy. Customizable reporting dashboards offer tailored insights to different stakeholders, enabling informed decision-making at all levels of the organization.