Real-Time Digital Production Boards

With real-time digital production boards, manufacturers can say goodbye to manual data entry and cumbersome physical boards. Instead, they can harness the power of technology to gain instant visibility into their hourly production activities. Let's explore the key benefits and features of incorporating real-time digital production boards into your manufacturing operations.

Real-Time Hourly Production Visibility

One of the significant advantages of digital production boards is the ability to monitor the ShopFloor in real-time. Without the need to physically visit the ShopFloor, manufacturers can instantly access crucial production data, including output rates, machine status, and production milestones. This visibility empowers decision-makers to identify and address any issues promptly, ensuring smooth operations and timely interventions.

Automate Production Analytics

Collaboration and communication are vital on the ShopFloor, and real-time digital production boards enable seamless interaction among team members. With the integration of smart applications and video walls, workers can collaborate on live data, share insights, and make informed decisions collectively.

Additionally, the automated shift changeover functionality upgrades the transition between shifts, eliminating time-consuming manual processes. Advanced analytics capabilities enable the system to calculate key performance indicators (KPIs) in real-time, providing valuable insights into production efficiency and identifying areas for improvement.

Production Tracking and Workflows

Tracking production progress and optimizing workflows are essential aspects of efficient manufacturing operations. Real-time digital production boards offer comprehensive tracking capabilities, enabling manufacturers to monitor the progress of individual orders, identify bottlenecks, and allocate resources effectively.

By leveraging smart applications on the ShopFloor, operators can access detailed information about each production step, ensuring smooth and error-free workflows.

Digitalizing production boards with a next-generation MES solution marks a significant step towards enhancing ShopFloor productivity. By eliminating the reliance on papers, clipboards, and whiteboards, manufacturers can leverage smart applications and video walls to streamline their operations. The benefits are numerous, including improved real-time visibility, automated production analytics, and optimized production tracking and workflows.

A Centralized View for ShopFloor Intelligence

Continuing the journey of enhancing your ShopFloor operations, now let's explore how you can achieve total ShopFloor control with a modern digital pacing board. This advanced solution provides you with a centralized view that empowers you to monitor, analyze, and collaborate effectively, all within a single platform. Say goodbye to fragmented data and siloed information - with this digital pacing board, you can update your ShopFloor intelligence and drive continuous improvements.

Plan Your Production

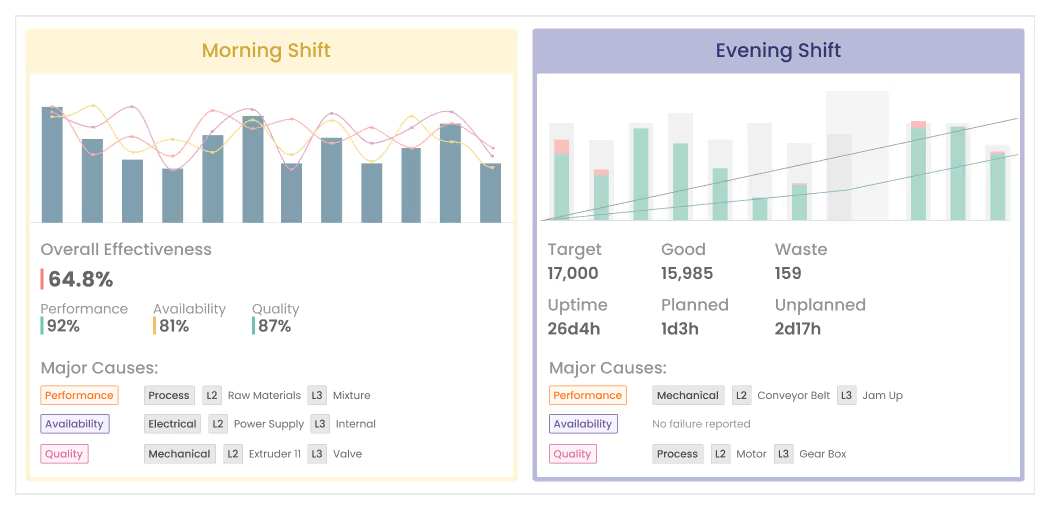

Gain comprehensive control over your production planning process with the digital pacing board. Utilizing 50+ data points, including metrics such as Rate, PAQ (Productivity, Availability, Quality), and OEE (Overall Equipment Effectiveness), you can effectively plan and allocate resources across all the lines in your manufacturing units.

This holistic view enables you to optimize production schedules, balance workloads, and maximize efficiency, resulting in improved productivity and reduced lead times.

Monitor the Process

Real-time data is the key to monitoring and managing your ShopFloor operations efficiently. The digital pacing board provides you with instant access to critical information such as work orders, line health, production targets, rates, capacity, and failure reasons. This real-time visibility allows you to proactively identify bottlenecks, track performance metrics, and ensure that production is aligned with your desired outcomes.

With ease-of-use and intuitive visualization, you can quickly interpret the data and make informed decisions to drive operational excellence.

Collaborate on Improvements

Data-driven decision-making is enhanced through effective collaboration. The digital pacing board enables you to analyze performance metrics quickly and collaborate seamlessly with teams in different factory locations. By sharing insights, discussing improvement opportunities, and leveraging the power of collective knowledge, you can drive continuous improvements across your manufacturing operations.

This collaborative approach ensures that everyone is aligned towards common goals and actively contributes to enhancing productivity, quality, and efficiency.

With a centralized view for ShopFloor intelligence, facilitated by the modern digital pacing board, you can optimize your production planning, monitor operations in real-time, and foster collaboration for continuous improvements. By leveraging the power of data, you can make proactive decisions, identify areas for enhancement, and drive efficiency throughout your manufacturing.

Transform Your ShopFloor into a Hub for Collaboration

A dynamic manufacturing environment, collaboration and seamless communication are essential for driving productivity and efficiency on the ShopFloor. With our smart Production Pacing Board, you can transform your ShopFloor into a collaborative hub that empowers your team to achieve new levels of performance.

This innovative solution, built on a modern Manufacturing Execution System (MES), is tailored to meet your unique requirements, providing bespoke features designed to enhance your ShopFloor operations.

Production Target Boards - From ShopFloor to Topfloor

Monitor progress towards shift targets and work orders seamlessly with Our Production Target Boards. This intelligent feature allows you to track and analyze production metrics in real-time, enabling you to make informed decisions and adjust strategies on the fly.

From start to finish, Kypeco's advanced capabilities automatically generate comprehensive insights and reports, equipping you with the precise information you need to take decisive actions.

By incorporating Our smart factory Production Pacing Board into your ShopFloor operations, you can foster a collaborative environment that drives productivity and enhances performance.

Here's how this solution can benefit your manufacturing processes:

- Real-Time Progress Monitoring

With Our smart factory Production Pacing Board, you gain real-time visibility into the progress of your shift targets and work orders. This allows you to track production metrics such as output rates, efficiency levels, and quality indicators, ensuring that you stay on top of your performance goals.

By having instant access to accurate and up-to-date information, you can make timely decisions and take proactive measures to address any deviations or bottlenecks. - Agile Strategy Adjustments

The ability to adjust strategies and adapt to changing circumstances is crucial for success in today's manufacturing landscape. Our smart factory Production Target Boards enable you to make agile adjustments based on real-time data insights.

By analyzing production trends, identifying areas for improvement, and collaborating with your team, you can optimize your operations and maximize productivity. This flexibility ensures that your ShopFloor remains aligned with your overall business goals, enhancing your competitiveness in the market. - Automated Insights and Reports

Say goodbye to manual data gathering and report generation. Our digital factory Production Pacing Board automates the process of generating insights and reports, saving you time and effort. You can access comprehensive analytics and performance metrics effortlessly, empowering you to make data-driven decisions.

These insights provide valuable visibility into your ShopFloor operations, enabling you to identify trends, uncover opportunities for improvement, and implement targeted strategies to enhance your production efficiency.

By embracing Our smart Production Pacing Board, you can optimize your ShopFloor into a collaborative hub that fosters communication, drives productivity, and achieves operational excellence. Leverage the power of real-time progress monitoring, agile strategy adjustments, and automated insights to elevate your manufacturing processes to new heights.

units.

Digital Monthly Production Board for Manufacturing Managers. No Paperwork. See how production boards work.

Digital Production Boards - Unified Production Analytics for Manufacturers

Continuing our exploration of empowering manufacturers with advanced solutions. These boards serve as a unified platform for production analytics, providing manufacturers with access, transparency, and real-time insights, all consolidated on a single dashboard. With this innovative approach, you can bid farewell to manual Excel formulas and data processing as our smart factory software handles the data accumulation and calculations for you, delivering comprehensive reports effortlessly.

Access, Transparency, and Real-Time Analytics

The three pillars of agility - access, transparency, and real-time analytics - converge on the digital production boards. Manufacturers can access critical production data and performance metrics with ease, eliminating the need for tedious data retrieval processes. The transparent nature of the boards ensures that stakeholders have a holistic view of production activities, allowing for informed decision-making and timely interventions. Real-time analytics empower manufacturers to stay up-to-date with the dynamic ShopFloor environment, enabling proactive adjustments and continuous improvement efforts.

A Unique Data Accumulation and Representation Approach

Digital production boards revolutionize data accumulation and representation, freeing manufacturers from the arduous task of manual data processing. By acquiring data once and leveraging Kypeco's sophisticated algorithms and calculations, you can transform raw data into valuable insights. The system automates the mathematical computations, generating comprehensive reports that provide a clear understanding of production performance, efficiency levels, and key indicators. This unique approach saves time, minimizes errors, and allows manufacturers to focus on analyzing insights and implementing strategic actions.

With digital production boards, manufacturers can harness the power of unified production analytics. Accessible data, transparent insights, and real-time analytics converge on a single dashboard, enabling agile decision-making and continuous improvement.

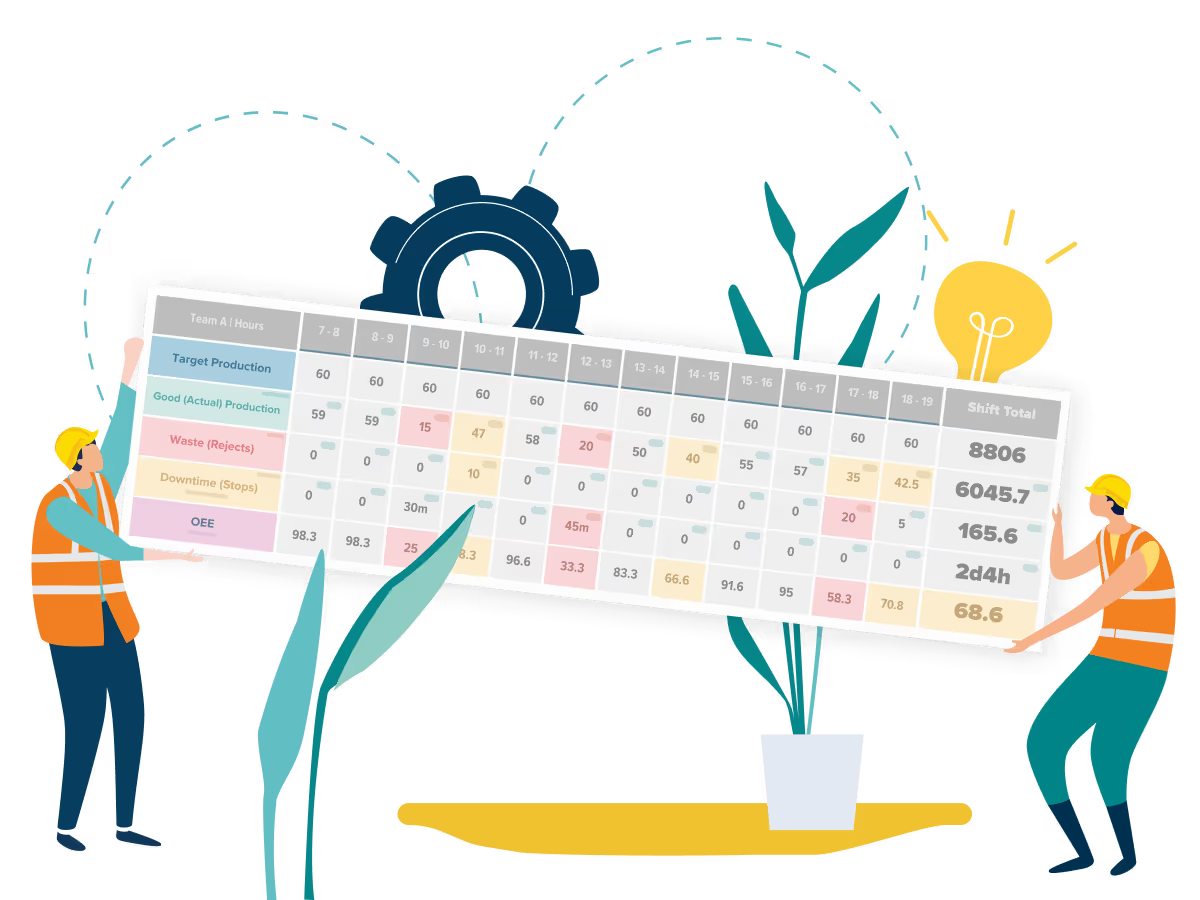

Digital hour-by-hour production analysis for Shopfloor. Remove paperwork and put video walls.

5 Digital Logbooks in one Manufacturing Software

1. Shift Production Board

Focus on production, not on calculations, with the Shift Production Board. This logbook is designed for the ShopFloor workforce and shift leads to track real-time updates and take timely actions. Acquire machine data from SCADA/OPCUA/IIoT or via smart apps, ensuring accurate and up-to-date information. Say goodbye to manual calculations and paperwork, and empower your team to drive productivity and efficiency on the ShopFloor.

2. Daily Production Board

Facilitate connected ShopFloor intelligence between shifts with the Daily Production Board. This logbook enables transparent shift handovers without any paperwork. Shift leads can collaborate seamlessly at work, ensuring a smooth transition between shifts. Automated insights keep teams motivated, involved, and informed, driving continuous improvement efforts throughout the production process.

3. Weekly Production Board

Optimize weekly production planning without wasting hours collating data on papers or sheets. The Weekly Production Board allows you to visualize your production schedule on a weekly basis, helping you meet monthly targets with ease. Gain a comprehensive view of the big picture and take early actions to ensure efficient production operations.

4. Monthly Production Board

Experience a production calendar for manufacturers with real-time insights for easy production management. The Monthly Production Board provides valuable monthly insights to help you plan better and improve production capacity and speed. Say goodbye to endless meetings and streamline your production scheduling process with a view specifically designed for managers.

5. Yearly Production Board

The Yearly Production Board caters to manufacturing managers and executives, offering a comprehensive logbook for your entire manufacturing operations. Get quarterly or annual reports that provide predictive planning capabilities with real-time insights. Make data-driven decisions without waiting for the data you need - have it readily available to drive strategic initiatives and optimize your manufacturing processes.

With 5 digital logbooks in 1 manufacturing software, you can optimize your production operations, enhance collaboration, and drive continuous improvements. Embrace the power of these digital logbooks to optimize your ShopFloor processes and achieve operational excellence in your manufacturing organization.

Production boards for every duration - save consulting cost with real-time digital Yearly Production Board.

Experience Digital Collaboration and Improve Productivity

Continuing our journey towards digital transformation, This advanced tool revolutionizes the way you collaborate and enhances productivity on the ShopFloor. With real-time data and intuitive features, you can set production capacity, monitor progress, and drive continuous improvement initiatives, all within an Advanced digital environment.

Set Production Capacity

The digital Production Pacing Board provides a clear view of production progress, enabling you to set the production pace effectively. With a comprehensive overview of the status of your production activities, you can easily allocate resources, adjust schedules, and optimize production capacity. This strategic planning allows you to maximize efficiency and ensure that your production processes align with your goals and customer demands.

Monitoring Production Progress

Real-time visibility is key to effective production management. The digital Production Pacing Board enables you to track production progress in real-time, empowering you to identify bottlenecks, delays, and potential issues that may impact the production pace. By promptly addressing these challenges, you can maintain a smooth and uninterrupted flow of production, ensuring timely delivery and customer satisfaction.

Continuous Improvement

The digital Production Pacing Board goes beyond monitoring and control - it also serves as a platform for continuous improvement. By analyzing production data and insights provided by the board, you can identify areas for improvement and implement changes to enhance production efficiency. Whether it's optimizing workflows, adjusting resource allocation, or implementing new strategies, the board enables you to measure the impact of these improvements and drive continuous progress in your manufacturing operations.

Real-time Production Data Points.

Take the next step to digitalize your site!

Production Workflow Management for Shopfloor

Modern Cloud Platform for Modern Manufacturing

Production Insights for Everyone

In the era of digital transformation, production insights are no longer limited to a select few - they are accessible to everyone involved in the manufacturing process. With a focus on acquiring data once and automating calculations, each data point holds value for someone, enabling informed decision-making and driving success in production operations.

Key Performance Indicators (KPIs)

Key performance indicators (KPIs) on a pacing board act as compasses for production teams, offering real-time snapshots of progress and highlighting areas that require attention. These KPIs steer the team towards success and ensure they stay on track to achieve their goals.

By having clear visibility of KPIs, the team can proactively address any deviations and take immediate action to prevent potential issues from derailing the production process. KPIs provide a unified focus and a shared understanding of production performance, driving alignment and fostering a culture of continuous improvement.

Record Job Failure Reasons

Recording failure reasons on a pacing board are akin to having a black box in an airplane. It helps the production team track failures, analyze root causes, and implement corrective actions. By documenting failure reasons, the team can improve processes, minimize errors, and achieve greater success.

Identifying the root cause of a problem is the gateway to unlocking a multitude of solutions, enabling the team to learn from mistakes, enhance quality, and drive efficiency.

Real-Time Data Visualization

A digital pacing board that showcases real-time production data with intuitive visuals, such as color-coding, graphs, and charts, serves as a window into the production process. It empowers the production team to spot issues and delays in real-time, fostering seamless collaboration for optimized production output.

The panoramic view of various data points on a pacing board provides a bird's eye perspective of the production process, enabling the team to see the big picture and make informed decisions. Real-time data visualization brings transparency, facilitates data-driven discussions, and enables swift actions for continuous improvement.

Wearable Production Board

The production board is no longer confined to the factory floor; it has become accessible on the go. Whether on a mobile device, smartwatch, or through voice command using devices like Alexa, the production board is always within reach.

Stay connected to your production process from anywhere, at any time, and easily identify areas for improvement. By taking the ShopFloor with you wherever you go, you can stay connected and stay in control, ensuring that production operations continue smoothly even when you are away.

With production insights accessible to everyone, manufacturing teams can make data-driven decisions, drive continuous improvement, and optimize production processes. Embrace the power of digital tools and real-time data visualization to empower your team, enhance collaboration, and achieve excellence in production operations.

Let our smart factory software handle your production process with our Digital production board.

It's time to upgrade your manufacturing processes and take control with our Digital Production Board. Our innovative solution is designed to revolutionize the way you manage and optimize your production process, providing you with the tools and insights you need for enhanced efficiency and success.

With our Digital Production Board, you can say goodbye to the headaches of manual data entry, paperwork, and the constant need for calculations. Our advanced factory software automates data collection and calculations, allowing you to focus on what truly matters – making informed decisions and driving productivity. From real-time monitoring and analytics to visualizing key performance indicators (KPIs), our Digital Production Board offers a comprehensive view of your production process, providing you with the insights you need to optimize operations and improve outcomes.

Imagine having a centralized platform where you can monitor production progress, identify bottlenecks, track KPIs, and collaborate seamlessly with your team. With Our Digital factory Production Board, you can achieve exactly that. Gain real-time visibility into your production metrics, identify areas for improvement, and make data-driven decisions with confidence. Our user-friendly interface and intuitive features make it easy for your team to adapt and embrace this digital transformation, ensuring a smooth transition and maximum productivity.

Don't just take our word for it – book a live demo today and experience the power of Our smart factory Digital Production Board firsthand. Our team of experts will guide you through the platform, demonstrating how it can revolutionize your production process and drive efficiency. See how our software can simplify your workflows, eliminate manual errors, and unlock the full potential of your manufacturing operations.

It's time to take control of your production process and experience the benefits of our Digital Production Board. Don't wait any longer – book a live demo today with IfElseCloud and embark on a journey toward optimized productivity and operational excellence. We're confident that once you see the capabilities of our platform, you'll be excited to embrace this digital transformation and revolutionize your manufacturing operations. Contact us now to schedule your live demo and discover the future of production management with IfElseCLoud.