Smart WorkOrder Scheduling Platform

Use the modern Job Management Solution for Shopfloor and automate the Production Scheduling Process. Create Complex Production Workflows to Simplify your Manufacturing. Create Production Workflows like Flowcharts. Run 'what-if' scenarios to improve Production Efficiency.

In today's fast-paced manufacturing environment, optimizing production scheduling is crucial for maximizing productivity and efficiency. A smart WorkOrder Scheduling Platform is the key to achieving these goals. Let's explore how such a platform can transform your manufacturing operations:

Pull Jobs from ERP System

Integrate with your ERP system and fetch Jobs to the WorkOrder Planning Software.

Efficient production scheduling begins with seamless integration between your WorkOrder Scheduling Platform and your ERP system. By pulling jobs directly from your ERP system, you eliminate manual data entry and ensure accurate and up-to-date job information. This integration streamlines the process and saves valuable time, allowing you to focus on more strategic tasks.

Use Smart Scheduler

Create workflows and drag-n-drop jobs to the lines. Analyze the best schedule for improved OEE.

A smart scheduler is the backbone of an efficient WorkOrder Scheduling Platform. With intuitive drag-and-drop functionality, you can easily create production workflows and assign jobs to specific production lines. The smart scheduler takes into account various factors such as machine capabilities, available resources, and production goals to generate the optimal schedule. This ensures improved Overall Equipment Effectiveness (OEE) and minimizes production downtime.

Optimize Job Workflow

Optimize your production workflow with smart work order algorithms to minimize the Takt Time.

Workflows are the foundation of any production process. With a smart WorkOrder Scheduling Platform, you can optimize your job workflow to minimize Takt Time. By leveraging intelligent algorithms, the platform analyzes job dependencies, resource availability, and production constraints to create an optimized workflow. This optimization reduces cycle times, eliminates bottlenecks, and enhances overall production efficiency.

Write Back Updates to ERP

Keep your ERP as the source of truth and write back real-time updates from the Shopfloor.

Maintaining data integrity and synchronization between your WorkOrder Scheduling Platform and ERP system is essential. With real-time updates, any changes made on the shop floor, such as job status updates or completion notifications, are automatically reflected in the ERP system. This ensures that your ERP system remains the single source of truth for accurate production data and enables better decision-making throughout the organization.

By leveraging a Smart WorkOrder Scheduling Platform, manufacturers can achieve significant improvements in their production scheduling processes. From seamless integration with ERP systems to intelligent scheduling algorithms, these platforms empower manufacturers to optimize their workflows, reduce lead times, and enhance overall production efficiency.

Next, we'll explore another essential aspect of modern manufacturing:

Maximize Efficiency with Precision: Unveiling the Game-Changer in Production Scheduling Software for Manufacturing.

Production Scheduling Software for Manufacturing

Production scheduling plays a critical role in achieving operational efficiency and meeting customer demands. Let's delve into how a Production Scheduling Software can revolutionize your manufacturing processes:

Automate Scheduling

Automate scheduling with AI-powered algorithms to optimize resource allocation and reduce lead times.

Gone are the days of manual scheduling processes that are time-consuming and prone to errors. A modern Production Scheduling Software leverages AI-powered algorithms to automate the scheduling process. By analyzing historical production data, customer demands, and resource availability, the software optimizes resource allocation and minimizes lead times. This automation enables manufacturers to respond quickly to changing production requirements and achieve greater agility in their operations.

Maximize Productivity

Maximize productivity with real-time updates and status tracking to improve Overall Equipment Effectiveness (OEE).

Real-time updates and status tracking are crucial for maximizing productivity on the shop floor. A robust Production Scheduling Software provides a centralized platform that offers real-time visibility into production activities. By tracking the progress of each job and capturing real-time data from the shop floor, manufacturers can identify bottlenecks, address issues promptly, and optimize resource utilization. This leads to improved Overall Equipment Effectiveness (OEE) and enhanced productivity across the entire manufacturing process.

Shopfloor Connectivity

Release a schedule and update the Shopfloor Board in real-time. The workforce is always up to date with the plan.

Maintaining seamless communication between the production scheduling software and the shop floor is vital for effective execution. With shop floor connectivity, manufacturers can release schedules directly to the shop floor and update digital production boards in real-time. This ensures that the workforce is always aware of the latest production plan, allowing for better coordination, reduced downtime, and improved overall operational efficiency.

As the manufacturing landscape continues to evolve, adopting a modern Production Scheduling Software becomes increasingly essential. By automating scheduling, maximizing productivity, and enhancing shop floor connectivity, manufacturers can optimize their operations, achieve higher efficiency, and stay competitive in a rapidly changing market.

An MES with WorkOrder Dashboards for Shopfloor

Manufacturing Execution Systems (MES) play a crucial role in managing shop floor operations and optimizing production workflows. Let's explore how an MES with WorkOrder Dashboards can empower manufacturers:

Run What-If Scenarios

One of the key features of an MES with WorkOrder Dashboards is the ability to run what-if scenarios. This allows manufacturers to simulate different production schedules and analyze potential bottlenecks or constraints. By identifying and addressing these issues proactively, manufacturers can optimize their production schedules, minimize disruptions, and maximize overall efficiency.

Predict the Production

Predictive capabilities are invaluable for efficient production scheduling. By leveraging historical data and advanced algorithms, an MES with WorkOrder Dashboards can accurately forecast production outcomes. This enables manufacturers to create optimized production plans that take into account factors such as resource availability, machine performance, and customer demand. With accurate predictions, manufacturers can make informed decisions, reduce lead times, and ensure on-time delivery.

Optimize Scheduling

Efficient job scheduling is essential for maximizing capacity utilization. An MES with WorkOrder Dashboards provides powerful tools to optimize the scheduling process. By considering factors such as job dependencies, machine capabilities, and workforce availability, manufacturers can create schedules that minimize idle time, reduce changeover durations, and maximize overall production capacity. This optimization translates into improved productivity and enhanced profitability.

Centralized Monitoring

Centralized monitoring is a game-changer for manufacturing operations. An MES with WorkOrder Dashboards provides a centralized platform that collects and displays real-time data from various sources on the shop floor. This data includes production metrics, machine performance, and workforce utilization. By gaining comprehensive insights into the shop floor operations, manufacturers can identify areas for improvement, plan for line upgrades, and make informed decisions about future investments.

Incorporating an MES with WorkOrder Dashboards into your manufacturing processes can significantly enhance efficiency, productivity, and decision-making capabilities. By running what-if scenarios, predicting production outcomes, optimizing scheduling, and leveraging centralized monitoring, manufacturers can achieve greater agility, profitability, and competitive advantage.

Empower and Innovate: Create Your Next Production Schedule with Smartness and Finesse.

Create Your Next Production Schedule with Smartness

Creating a production schedule that optimizes resources, minimizes downtime, and meets customer demands requires a smart approach. Let's explore how manufacturers can leverage smartness to create their next production schedule:

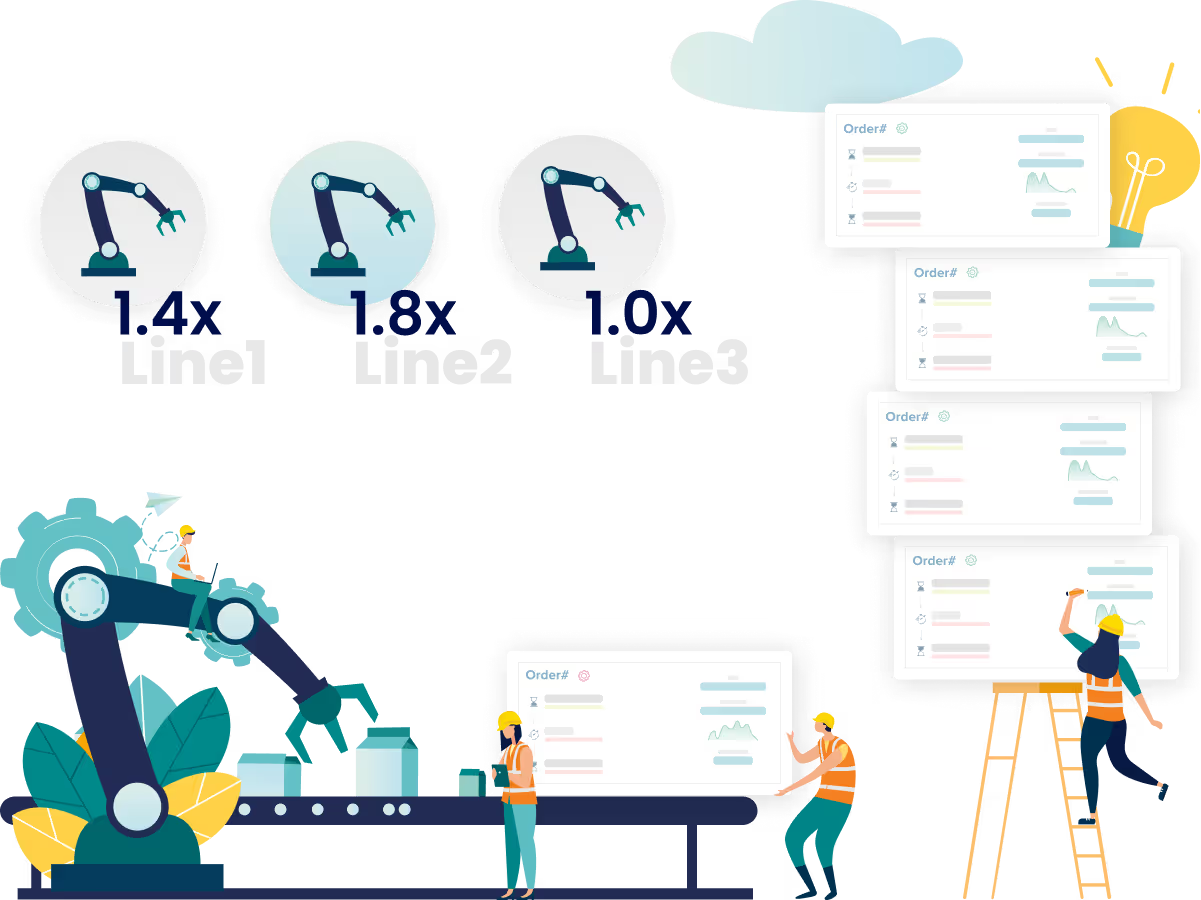

Historical Production Data Loop

Analyze your production lines to identify their strengths and weaknesses and gain valuable insights that inform your work order scheduling decisions.

Harnessing the power of historical production data is key to creating an optimized production schedule. By analyzing data from past production cycles, manufacturers can identify patterns, identify bottlenecks, and uncover opportunities for improvement. These insights allow manufacturers to make informed decisions when scheduling work orders, ensuring the most efficient allocation of resources and maximizing overall productivity.

Find the Best Production Lines

With data-driven insights, schedule work orders on the production lines that are best suited for the job, optimizing efficiency and productivity.

Every production line has its strengths and limitations. By leveraging data-driven insights, manufacturers can identify the production lines that excel at specific tasks or processes. By assigning work orders to the most suitable lines, manufacturers can optimize efficiency, reduce cycle times, and enhance productivity. This smart approach ensures that each job is assigned to the best-suited line, leading to better quality and faster turnaround times.

Gain High Throughput

Optimize your manufacturing process with smart work order scheduling, reducing downtime and increasing overall efficiency.

High throughput is a key objective for manufacturers. By implementing smart work order scheduling, manufacturers can minimize downtime and maximize productivity. By strategically sequencing work orders and minimizing changeover times, manufacturers can achieve a smooth and uninterrupted flow of production. This results in increased throughput, reduced lead times, and improved overall efficiency.

In the ever-evolving manufacturing landscape, embracing smartness in production scheduling is essential. By leveraging historical production data, scheduling work orders on the best production lines, and optimizing for high throughput, manufacturers can create production schedules that maximize efficiency, productivity, and profitability.

Real-time Jobs Completion Insights

Take the next step to digitalize your Workorder Process!

Production Workflow Management for Shopfloor

Workorder Scheduling Software for Industry 4.0

Schedule WorkOrders on Machines with the Intelligence of Machine Learning

Automation and ML algorithms enable intelligent scheduling based on line efficiency and historical data. Our platform facilitates scheduling based on the machine's ability to manufacture specific SKU, further improving efficiency and reducing downtime.

Efficiently scheduling work orders on machines requires intelligent decision-making based on machine capabilities, historical data, and SKU-specific requirements. Let's explore how the intelligence of machine learning can revolutionize work order scheduling:

Modern MES for WorkOrder Planning

Transform your manufacturing process with smart work order scheduling with ease and experience the smooth operations.

A modern Manufacturing Execution System (MES) equipped with intelligent work order planning capabilities streamlines the scheduling process. By leveraging machine learning algorithms, the MES analyzes various factors, such as machine capacities, SKU-specific requirements, and historical data, to create optimized work order schedules. This ensures efficient utilization of machines, minimizes downtime, and facilitates smooth operations on the shop floor.

A Smart Scheduling Smart Phone App

Available on both Android and iOS - phones and tablets to keep you connected with the Shopfloor.

To enhance mobility and accessibility, a smart scheduling smart phone app complements the MES. With this app, manufacturers can access work order schedules, update job statuses, and view real-time data from anywhere on the shop floor. The app ensures that production supervisors and operators stay connected and informed, enabling them to make informed decisions and adjustments on the go.

Integrate with ERP System

Say goodbye to the hassles of manual work-order entry and embrace the ease of a modern platform! Integrating existing ERP or e-commerce systems with our platform is a breeze - all your work orders can be imported automatically or within a few clicks.

Integrating the MES with your ERP system streamlines the work order management process. By automatically importing work orders from the ERP system into the MES, manufacturers eliminate the need for manual data entry and reduce the chances of errors. This integration ensures that the work order schedules are up to date and synchronized across systems, enhancing operational efficiency and accuracy.

Optimize Workflow. Increase Productivity.

Improve operational efficiency by optimizing the time and sequencing of work orders.

A key advantage of intelligent work order scheduling is the optimization of workflows. By analyzing machine capacities, SKU-specific requirements, and production constraints, the scheduling algorithm generates an optimized sequence of work orders. This optimization minimizes idle time, reduces changeover durations, and improves overall productivity. Manufacturers can achieve better resource utilization and maximize throughput by implementing this optimized workflow.

By leveraging the intelligence of machine learning in work order scheduling, manufacturers can streamline their operations, reduce downtime, and enhance productivity. The combination of a modern MES for work order planning, a smart scheduling smartphone app, seamless ERP integration, and workflow optimization brings unprecedented efficiency and effectiveness to the manufacturing process.

Unleash Efficiency: The Agile Jobs Scheduler for Dynamic Manufacturing Environments.

Agile Jobs Scheduler - Mobile and Tablet Smart Device Application

Connected with the ERP and the Digital Shopfloor Production Boards. Get real-time updates every time.

Agility is a critical aspect of modern manufacturing. An agile jobs scheduler enables manufacturers to adapt quickly to changing production requirements and optimize job sequencing. Let's explore the benefits of an agile jobs scheduler:

Agile Board for Smart Scheduling

Simplify your production scheduling with an agile board scheduling that allows you to easily manage and prioritize jobs on-the-go.

An agile board for smart scheduling provides a visual interface where manufacturers can manage and prioritize jobs in a flexible and intuitive manner. The agile board allows for quick adjustments, re-prioritization, and real-time updates. This simplifies the production scheduling process and enables manufacturers to respond rapidly to changes in demand or production constraints.

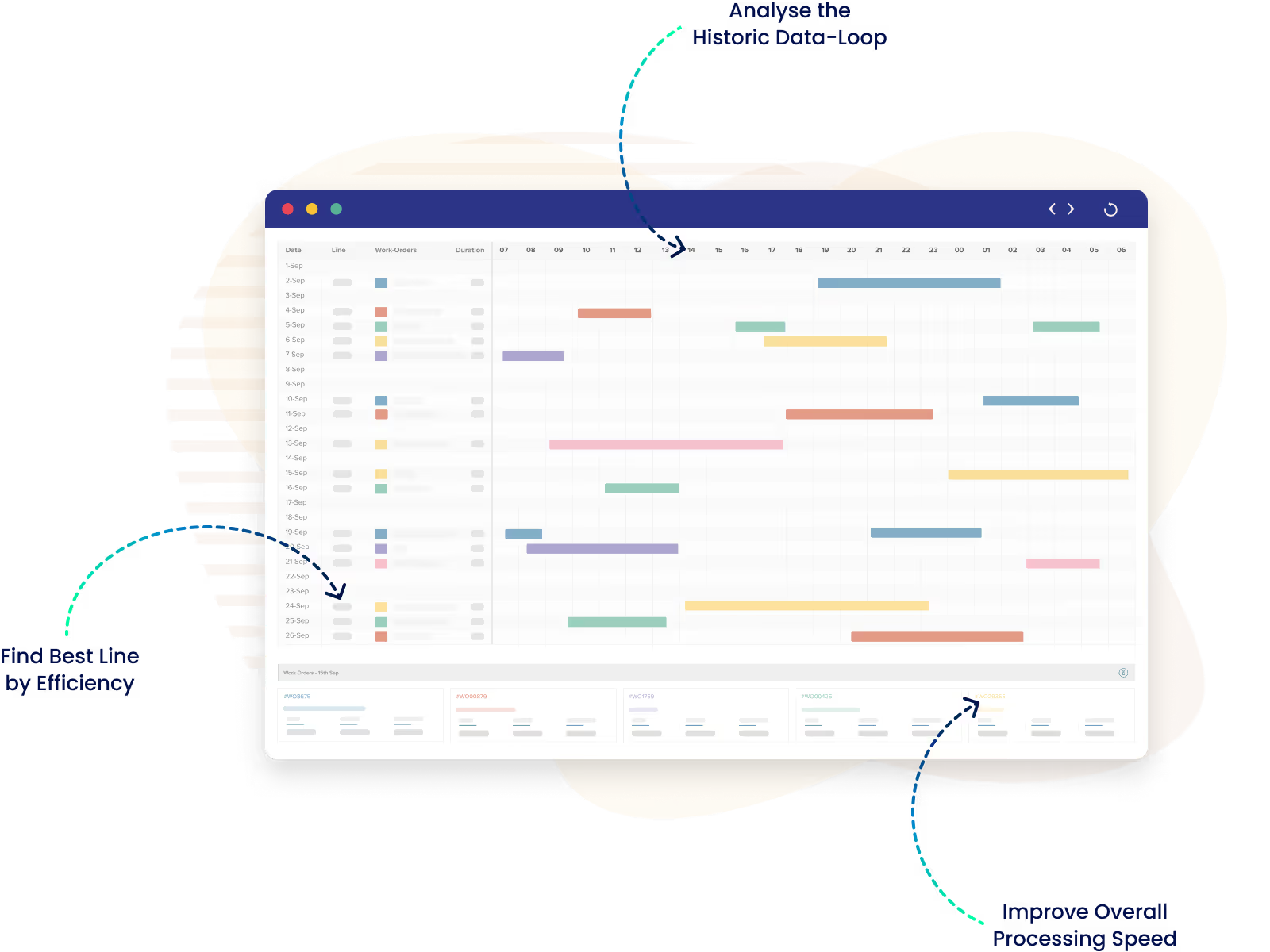

Calendar for Jobs Scheduling

Stay on top of your shop floor production schedule with a calendar-style visualization that provides a clear overview of your work orders and deadlines.

A calendar-style visualization provides a comprehensive view of the production schedule, allowing manufacturers to stay organized and informed. By displaying work orders, deadlines, and resource availability, the calendar enables better planning, coordination, and resource allocation. Manufacturers can easily identify potential scheduling conflicts, optimize production sequences, and ensure on-time delivery.

Gantt Board for Jobs Planning

Plan and run the schedule with ease using a Gantt-style planning feature that enables you to create and manage jobs, dependencies, and timelines.

A Gantt board for jobs planning offers a powerful tool for creating and managing work order schedules. Manufacturers can visualize the dependencies between tasks, allocate resources, and define timelines. This level of detail and control allows for precise scheduling, efficient resource utilization, and seamless coordination between different stages of production. The Gantt board simplifies job planning and enhances overall operational efficiency.

SERP Integration for Job Planning

Get even more flexibility with our spreadsheet-style scheduling feature that allows you to view, edit, and update your jobs in a familiar, intuitive format.

Integrating the agile jobs scheduler with the ERP system brings enhanced flexibility and ease of use. With a spreadsheet-style scheduling feature, manufacturers can view, edit, and update jobs in a format that is familiar and intuitive. This seamless integration enables efficient communication between the agile jobs scheduler and other systems, ensuring accurate and up-to-date information across the production process.

An agile jobs scheduler empowers manufacturers to respond quickly to changing demands, optimize job sequencing, and improve overall production efficiency. The combination of agile board scheduling, calendar visualization, Gantt-style planning, and ERP integration offers a comprehensive solution for effective job scheduling and execution.

Transforming Shopfloors: The Power of Modern Production Scheduling Software with Integrated Intelligence.

Modern Production Scheduling Software with Integrated Shopfloor Intelligence

Streamline work order management, reduce errors, and drive efficiency with our advanced Smart Work Order Management solution designed for modern manufacturers. A modern platform on Web, Mobile, and Tablets to provide you the best experience of smart software in manufacturing.

A modern production scheduling software equipped with integrated shopfloor intelligence brings a host of benefits to manufacturers. Let's explore how this advanced solution can revolutionize work order management:

Integrate with ERP

Integrate with your ERP system to pull the open Work Orders and seamlessly schedule them to the production lines. Update the job status in the ERP or Warehouse Management System.

Seamless integration between the production scheduling software and the ERP system is essential for efficient work order management. By integrating with the ERP system, manufacturers can automatically pull open work orders into the scheduling software, eliminating manual data entry and reducing the chance of errors. This integration ensures that work order schedules are synchronized across systems, providing real-time visibility and streamlining the overall workflow.

Real-time Work Order Updates

Access real-time work order status, enabling rapid response to changes and improved decision-making. Keep the sales team up to date with the shopfloor activities without writing emails.

Real-time work order updates are crucial for effective decision-making and collaboration. With integrated shopfloor intelligence, manufacturers can access real-time work order status, track progress, and receive instant notifications of any changes or issues. This enables swift responses to changes, minimizes delays, and keeps all stakeholders, including the sales team, informed of the shopfloor activities without the need for lengthy email exchanges.

Automate Work Order Management

Automate work order assignment and tracking to increase overall shopfloor efficiency.

Manual work order management processes are prone to errors and inefficiencies. A modern production scheduling software automates work order assignment and tracking, reducing the reliance on manual intervention. By leveraging predefined rules and intelligent algorithms, the software automatically assigns work orders to the appropriate resources, tracks their progress, and captures real-time data. This automation improves shopfloor efficiency, reduces administrative overhead, and enables better resource utilization.

Flexibility and Customization

Accommodate unique shopfloor requirements with our customizable work order management solution.

Every manufacturing facility has its unique requirements and workflows. A modern production scheduling software offers flexibility and customization options to adapt to different shopfloor environments. Manufacturers can configure the software to align with their specific processes, define custom workflows, and incorporate industry-specific rules. This level of customization ensures that the work order management solution seamlessly integrates with existing operations and meets the specific needs of the manufacturing facility.

Work Order Analytics

Leverage powerful analytics to identify trends, optimize processes, and drive continuous improvement.

Data-driven insights are invaluable for continuous improvement and optimization. With integrated work order analytics, manufacturers can analyze key metrics and performance indicators related to work orders. By identifying trends, bottlenecks, and areas of improvement, manufacturers can make informed decisions, optimize processes, and drive continuous improvement. Work order analytics provide actionable insights that lead to better resource allocation, reduced costs, and enhanced overall efficiency.

Incorporating a modern production scheduling software with integrated shopfloor intelligence offers manufacturers a comprehensive solution for efficient work order management. By integrating with ERP systems, providing real-time updates, automating work order management, offering flexibility and customization, and leveraging work order analytics, manufacturers can streamline their operations, reduce errors, and drive productivity.

Ready to enhance Production Capacity and Efficiency with Smart Work Order Scheduling

Empowering Manufacturing with Intelligent Work Order Management

In conclusion, intelligent work order management is the cornerstone of efficient and agile manufacturing operations. By leveraging smart work order scheduling platforms, production scheduling software, and integrated shopfloor intelligence, manufacturers can optimize resource allocation, minimize downtime, and enhance overall productivity.

Our product, equipped with advanced features such as Production Board, Work Order Management, Maintenance Planner, Shopfloor Intelligence, and Reporting and Insights, offers a comprehensive solution to modern manufacturers. With real-time insights using machine learning and AI, integration with IIoT, SCADA, OPCUA, ERP, and other on-prem systems, our product empowers manufacturers with the tools to streamline their operations, improve decision-making, and drive continuous improvement.

Maximize your manufacturing efficiency, reduce lead times, and achieve greater agility with our intelligent work order management solution. Experience the benefits of a modern platform, accessible on web, mobile, and tablets, and take your manufacturing processes to the next level.

Contact us today to learn more about how our product can revolutionize your work order management and enhance your manufacturing operations.