The Semiconductor industry often struggles with manual processes, paperwork, siloed data, low OEE, and a lack of modern software, which leads to technical debt and slows down progress. Without digital automation, the workforce can struggle to focus on manufacturing and achieving production goals.

Kypeco MES is a comprehensive software solution that addresses these challenges and optimizes Semiconductor manufacturing processes. With Kypeco MES, manufacturers can improve OEE, improve quality, reduce downtime, remove paperwork, and automate reports. It enables manufacturers to use advanced technologies like ML and AI to monitor and improve processes, digitalizes the manufacturing processes, and attract a younger workforce.

Kypeco MES is a key step in advancing Semiconductor manufacturing and enabling the industry to embrace digital transformation and Industry 4.0 concepts. With Kypeco MES, manufacturers can gain end-to-end visibility and control over their supply chain, optimize resources, and achieve greater agility. Ultimately, Kypeco MES is a vital tool in progressing toward Smart Industry Readiness and driving innovation in the Semiconductor industry.

Embrace the power of digital technologies and move away from paper-based systems. Smart MES apps can help you upgrade workflows, automate processes, and improve efficiency, allowing you to stay ahead of the competition.

The future of manufacturing is here, and it's all about innovation and efficiency. Stay ahead with new MES technology in Semiconductor manufacturing industry.

Gain real-time insights into operations of semiconductor industry with modern MES cloud and Industrial Technologies.

Our MES re-evaluating production processes can optimize workflows and enhance productivity.

Experimenting with data-driven decision making can help in identifying trends and new growth with Modern MES.

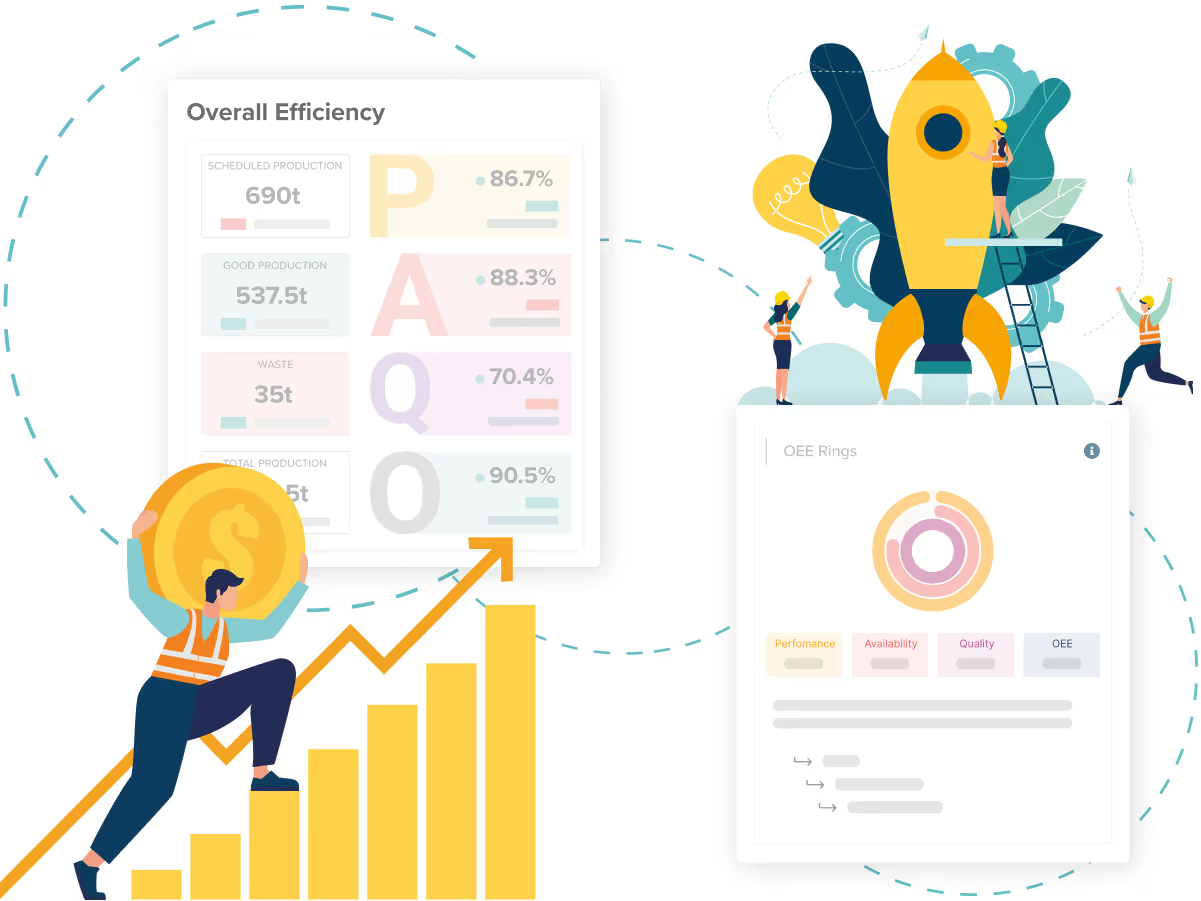

Boosting overall efficiency with modern MES requires a holistic approach that considers performance, availability, and quality. By focusing on all three, you can unlock new levels of success in Semiconductor manufacturing industry.

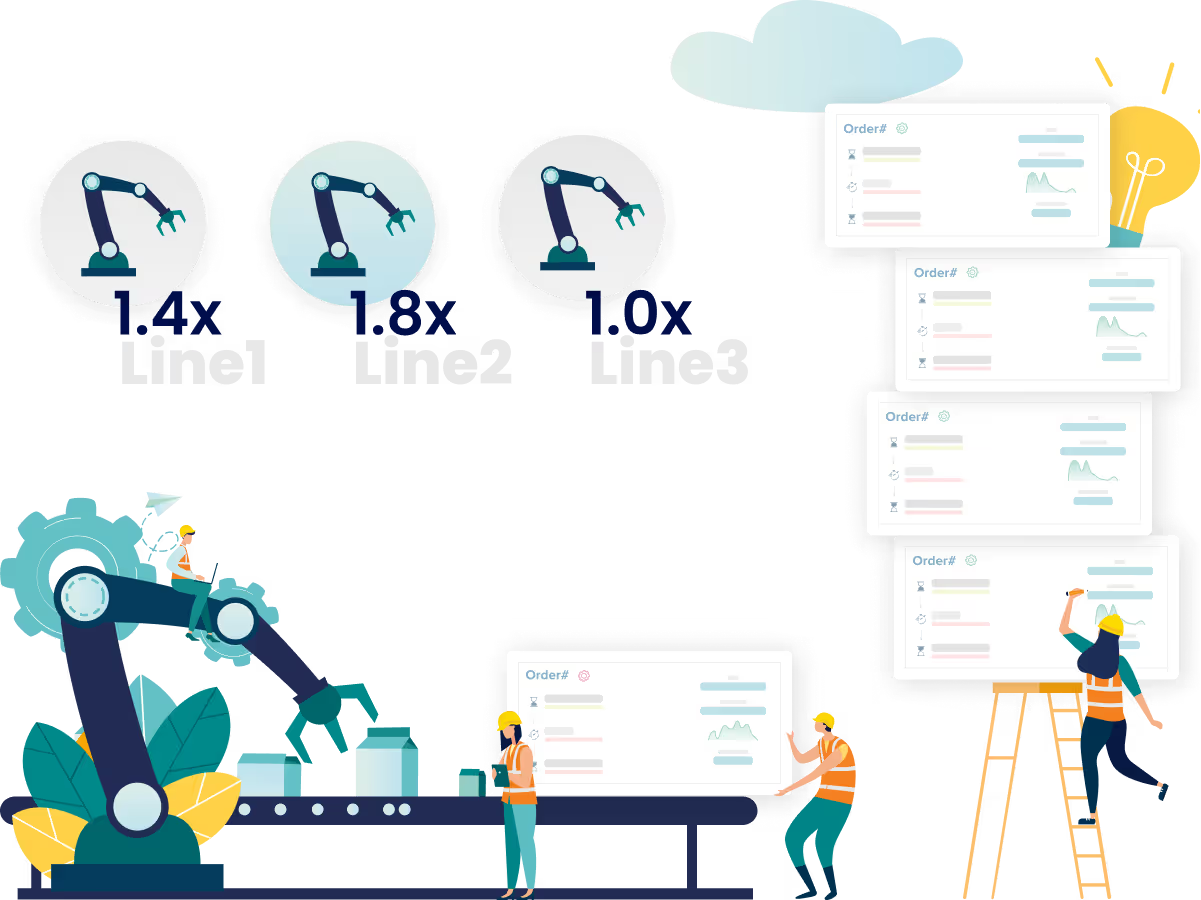

Effective line efficiency monitoring can help in identify bottlenecks, eliminate waste, and more with our modern MES.

Improve visibility into operations and enhance business performance with the MES production line dashboard.

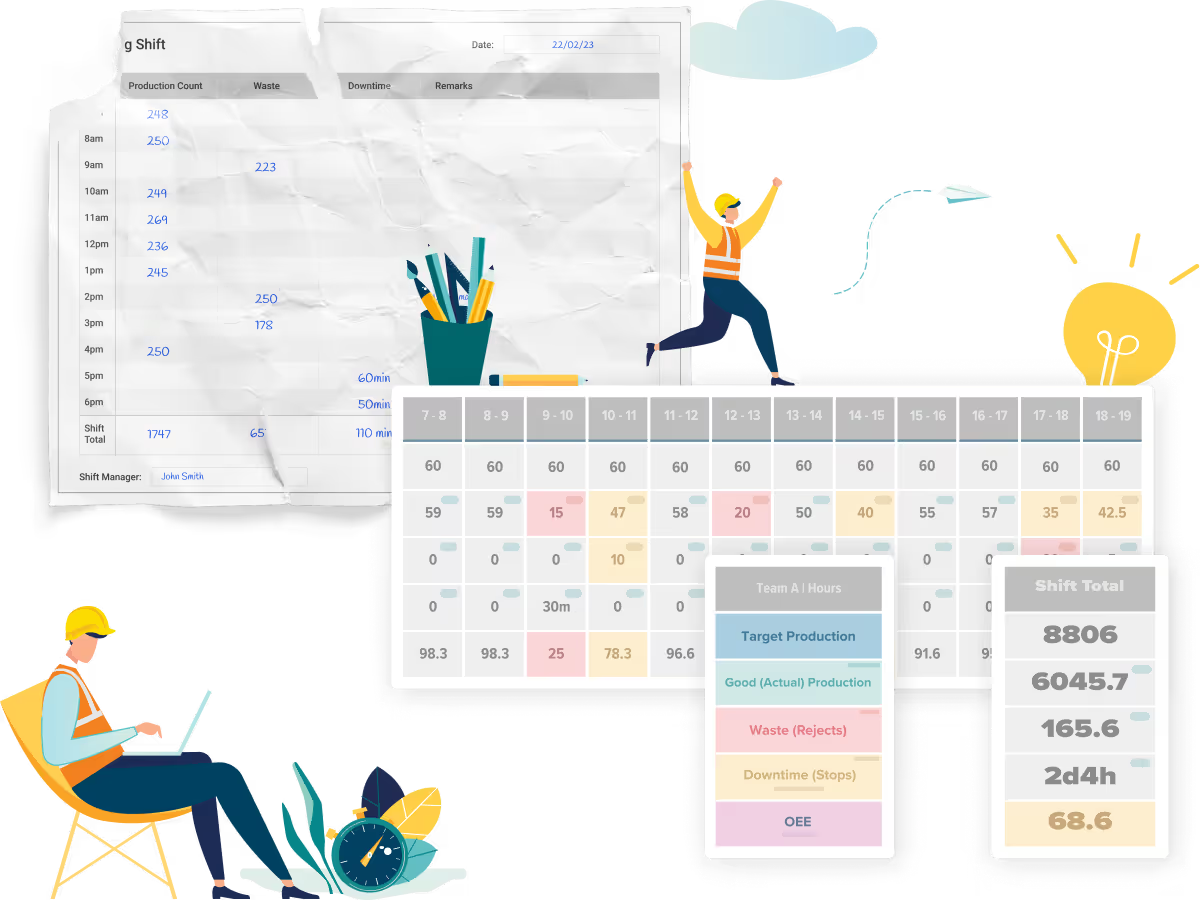

Ensure that production remains on schedule, and quality is consistently high with our MES Pacing Board.

By analyzing failure reasons, manufacturers can improve quality and reduce downtime with our MES.

The next generation of workers has grown up with technology and expects it in the workplace. By providing next-gen MES technology, Attract and retain top talent with our MES solutions in Semiconductor manufacturing industry.

Our paperless MES solutions can help update workflows, increase productivity, and reduce cost. Attract younger workforce.

To build for the younger workforce, manufacturers need to embrace next-gen MES tech, such as automation, AI, and IoT.

Our MES outlook for manufacturing is evolving rapidly, and whoever adapt and innovate are best positioned for success in the years ahead.

With mobile accessibility, Gain real-time insights into production processes, enabling them to make informed decisions.

Your private assistant in asset management can help manufacturers identify underperforming assets, reduce waste, and improve overall efficiency with our MES.

Gain real-time visibility into equipment performance, enabling them to take proactive measures to improve productivity with the MES.

Identify potential issues and take preventive measures before equipment failure occurs, leading to increased efficiency.

Identify and repair issues in a timely manner, reducing the risk of costly equipment downtime and repairs.

By monitoring MTTF, Identify potential issues before equipment failure occurs, leading to increased reliability and efficiency.

The use of ML and AI in work order management enables to predict potential issues and take preventive measures before equipment failure occurs and schedule tasks with our MES.

Smart scheduling technology helps in staying ahead of competition by improving overall operational efficiency with the MES.

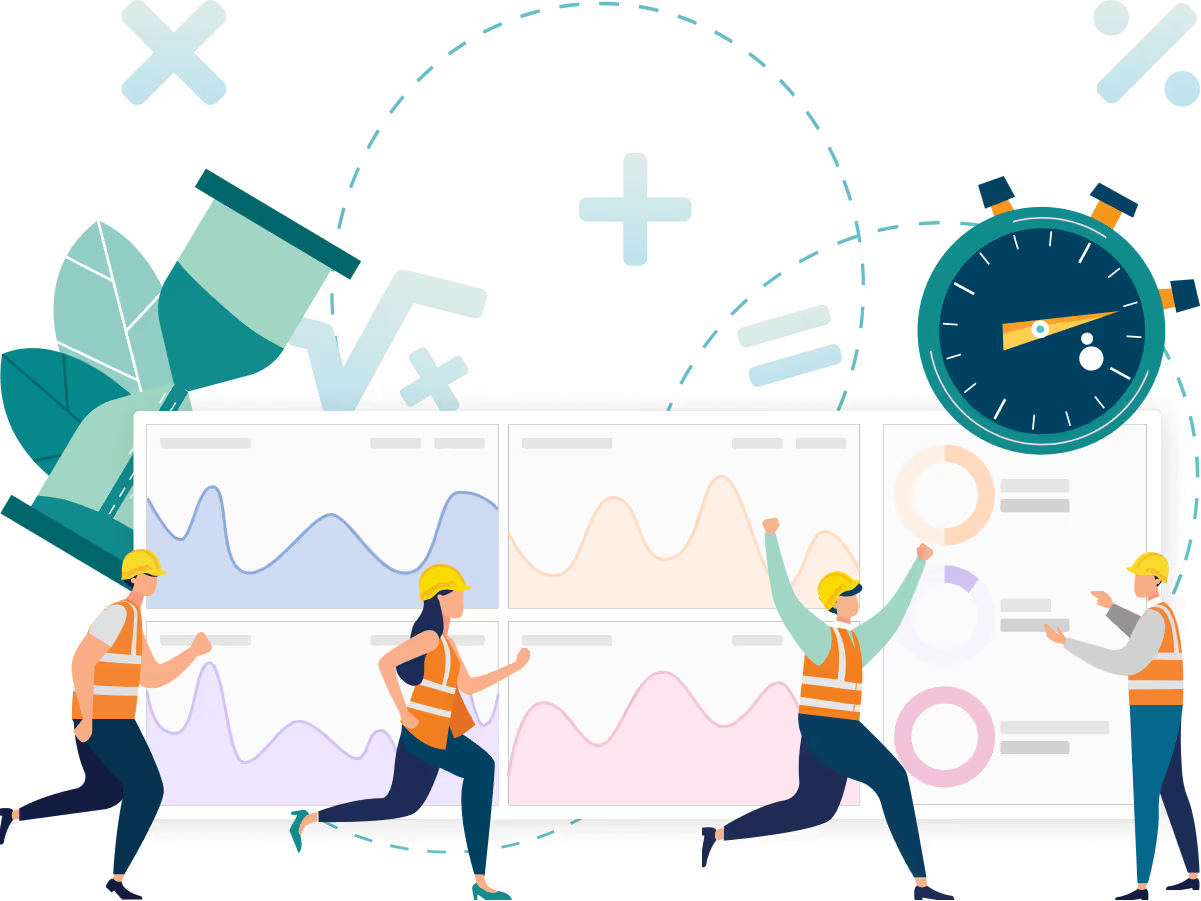

Interactive visualization options helps explore data and uncover insights that might be hidden in static reports.

Assign tasks quickly and efficiently with automated scheduling, reducing burnout and improving job satisfaction.

Reduce order fulfilment times, increase order accuracy, and improve overall customer satisfaction with ERP & E-Commerce.

Optimize preventive maintenance activities, enhance asset management, and achieve operational excellence with the help of our advanced MES maintenance planning and scheduling.

Enhance maintenance workflows with visual planning tools that helps prioritize tasks, optimize resources, and minimize downtime.

Plan and schedule maintenance tasks effortlessly with Gantt and calendar style views in the modern MES.

Effortless maintenance planning by setting up recurring modern MES maintenance for better operations.

Keep assets in top condition & minimize downtime with SOPs for breakdown maintenance with the MES.

Enhance decision-making capabilities with our modern digital platform for automated and real-time reporting, providing comprehensive insights into Semiconductor manufacturing operations.

Stay organized and on track with our digital platform, and reduce the need for manual tracking on whiteboards or paper.

Gain visibility into manufacturing operations and make informed decisions with complete transparency.

Enhance business transformation strategic planning and get actionable insights with our MES.

Track return on investment (ROI) and cost savings to justify investments and identify areas for improvement with our MES.

With the Modern digital MES, Create a shared vision and understanding of key metrics and goals, leading to more effective collaboration across teams with centralized data.

Eliminate data silos and enhance cross-functional collaboration with centralized data, empowering teams with better insights in our MES platform.

Share, store, and access project files and documents from a centralized platform, anytime with the digital MES collaboration.

Empower all team members with equal access to critical information, improving operations and collaboration.

Foster a culture of continuous learning and growth with digital MES feedback that inform strategic decision-making.

Gain a competitive advantage in semiconductor manufacturing by tapping into the potential of manufacturing data, making informed decisions that boost efficiency and drive growth with the help of our MES.

Optimize schedules, reduce downtime, and improve quality by harnessing data-driven insights for informed manufacturing decisions

Identify and address the root causes of issues, improving product quality and reducing downtime with our modern MES.

Analyze production data with our MES to identify patterns and trends, driving continuous improvement and growth.

Maximize profits by optimizing costs and minimizing losses with data-driven insights and smarter processes.

With our white-label MES platform, you can maintain brand consistency while customizing features and workflows to fit your Semiconductor manufacturing industry.

Tailor our MES to your specific manufacturing needs with flexible customization options, allowing for seamless integration with your existing systems.

With our MES, track and measure production KPIs and OEE to identify areas of improvement and boost efficiency.

In our MES, personalize your user interface with your preferred language and branding.

Flexible SKU, failure, and asset customization for more accurate reporting and analysis in Semiconductor manufacturing industry.

120+

Our real-time alerting system notifies users of critical data changes or anomalies in real-time, enabling swift actions, and helping with the lack of real-time data visibility.

Our data governance framework ensures compliance with data standards, supporting accurate data management.

Kypeco's API-driven architecture enables seamless data exchange between different systems, facilitating collaboration and helping in finding siloed data.

Enhancing data traceability through our metadata management capabilities enables the industry to capture and manage metadata.

Kypeco enables organizations to compare their production processes to industry best practices, promoting process optimization.

Our data access and reporting capabilities enable organizations to make informed decisions and respond quickly to changes in demand.

Kypeco's quality management features ensure that production processes meet quality standards, supporting process optimization.

Enable organizations to identify and address bottlenecks and inefficiencies in real-time, facilitating quick resolution with the help of continuous monitoring.

Kypeco's analytics capabilities enable organizations to analyze maintenance data and identify process improvement and efficiency opportunities.

Kypeco helps industries monitor and manage shop floor operations from anywhere, and identify bottlenecks in production.

Our continuous improvement framework promotes a culture of ongoing waste and scrap reduction and process optimization.

Kypeco's capabilities enable organizations to forecast production costs accurately, enabling better decision-making and cost optimization.

This capability enables organizations to develop innovative products and services, enhancing competitiveness and customer value.

Enable organizations to facilitate collaboration among employees, improving employee engagement and attraction

Enable organizations to provide employees with flexible work arrangements and support work-life balance, enhancing employee engagement and retention.

Kypeco's capabilities enable organizations to identify bottlenecks in their processes, enhancing process efficiency and attracting top talent.

Kypeco enables organizations to share knowledge across departments, enhancing collaboration and innovation.

Kypeco's analysis features enable organizations to analyze and optimize processes, reducing manual labor costs.

Enable organizations to forecast production volumes accurately, track production costs, and make informed decisions for cost optimization.

Kypeco's features enable organizations to involve multiple stakeholders in decision-making, enhancing decision-making speed and alignment.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the semiconductors industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your semiconductors manufacturing operations.