Real-time production monitoring, integration with the Industrial Internet of Things (IIoT), SCADA, PLCs, AI and Machine Learning capabilities for smart manufacturing, predictive maintenance tools, Shopfloor management, and data analytics for continuous improvement - the wait is over!

Don't waste time searching for data in silos. Get real-time insights to make data-driven decisions.

Get automated reports generated on time, with integrated Machine Learning and AI.

Simplify the Shopfloor management with our NextGen MES. Streamline operations, reduce downtime, and increase output.

Eliminate manual processes and streamline operations for increased efficiency. Automate manual tasks, monitor production in real-time, and analyze performance data for actionable insights.

Upgrade to the NextGen Manufacturing Execution System (MES) Platform to attract and retain the best talent in the industry. Unify your teams on a single Unified Production Software.

1sec

Granularity of the

Production Data

18

Levels of

Data Aggregation

100+

Manufacturing

Properties Analysed

15+

Manufacturing

Roles Supported

12+

Manual Processes

Made Redundant

Leverage predictive analytics to gain valuable insights and optimize your manufacturing processes.

Develop an agile plan to achieve your manufacturing goals and respond to market changes.

Track progress in real-time and adapt your strategies on the fly with the latest MES technologies.

30+

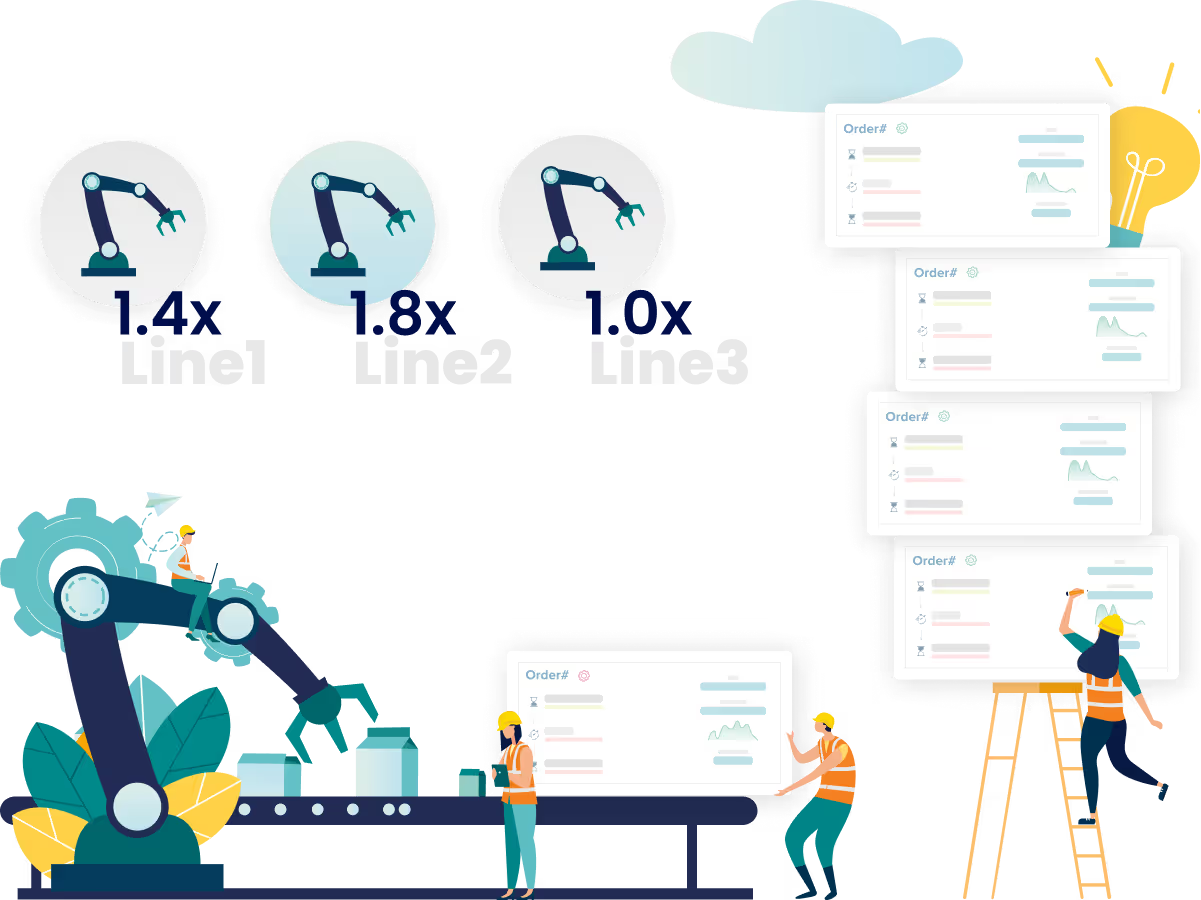

It's now possible to monitor all your manufacturing sites from one centralized location, no matter where you are or what time it is. Our advanced MES provides you with real-time alerts and notifications so you can stay on top of any issues, even when you're not physically on site.

Our advanced site monitoring solution helps you meet your entire manufacturing site's goals and discover areas to improve.

Prioritize improving the performance of the least productive line, to bring all lines up to a more consistent level of productivity.

Reduce the backlog time on assembly lines and balance the workload to improve overall efficiency.

Schedule work orders based on the line with the shortest Takt Time and improve output of other lines.

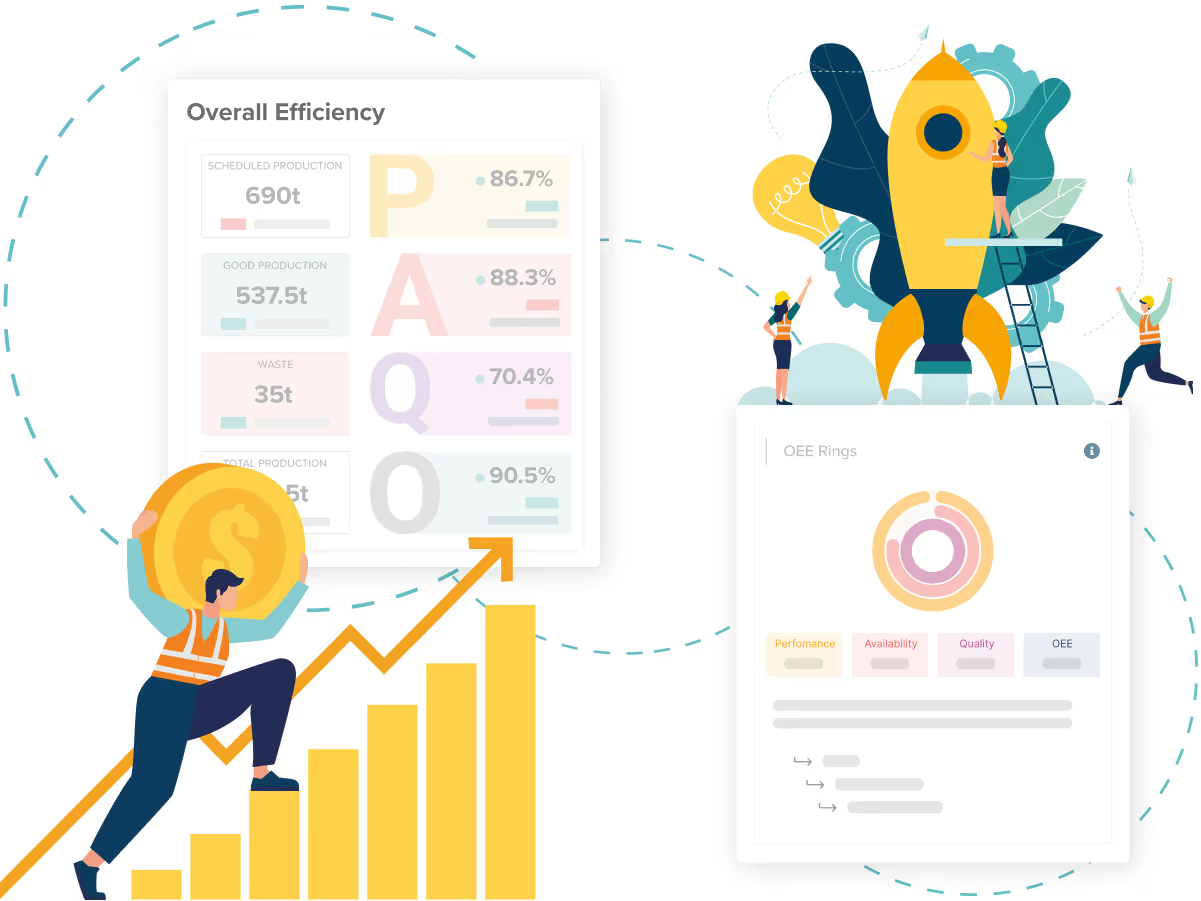

When tracking the efficiency of a production line, relying on a single data point is often not sufficient. To gain a more comprehensive understanding, it is important to collect and analyze multiple data points. Right? So why wait?

OEE is the heartbeat of any successful manufacturing operation - it's the engine that drives efficiency, productivity, and profitability. With dashboards in Kypeco, unlock your true manufacturing potentials.

Reduce downtime and lead times to ensure on-time delivery to respond quickly to customer demand.

Increase output, reduce costs, and improve the quality of the products.

Identify the optimal balance between the resources used and the output produced by line.

Upgrade your meeting rooms with videowalls to enhance communication and collaboration, and keep your team focused on tasks at hand. Get simplified data collection and analysis, which gives you real-time insights into your operations, and helps you make informed decisions.

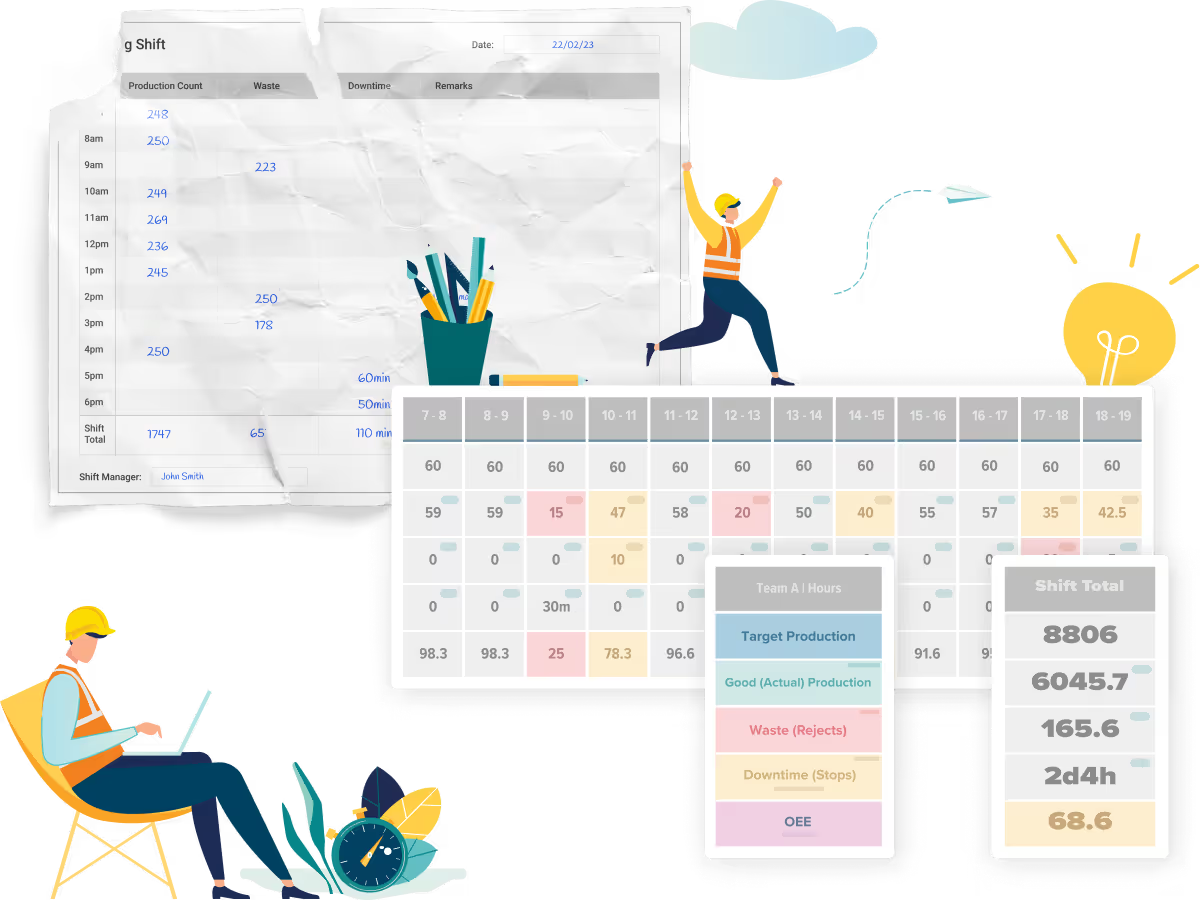

Get rid of manual data entry and difficult calculations and automate the manufacturing process with seamless data acquisition and analysis by using Digital Logbook - whiteboard to Colorful board!

Track the availability of equipment, materials, and labor, and factor this into the production scheduling.

Get insight into periods of no production with a single click.

Identify anomalies detected using deviations from expected patterns.

Do you want to attract and retain a skilled and motivated workforce in your manufacturing operation? Here we are! You can incorporate smart applications, go paperless, and offer workers interesting tasks that will keep them engaged and productive.

Revolutionize your collaboration process with our smart solution - eliminate paper-based tasks and go digital. Streamline communication and information sharing for increased efficiency and productivity.

Why not treat Kypeco as Outlook? Use mobile, tablets, smart watch, Alexa, whichever you like!

Transparent data makes work more competitive and enjoyable - like a Game!

Centralized insights encourages a more open and collaborative workplace culture.

Optimize Workflow with Smart Scheduling: Efficiently Manage Tasks and Save Time!

Effortlessly Organize Equipment Maintenance with Planner: Maximize Uptime and Minimize Downtime!

50+

Critical data insights such as failure reasons, trends, equipment utilization, loss and cost analysis. Identify patterns in operations and optimize resources for better improvement.

Set the patterns into a feedback loop, to make continuous improvements for better performance and reduce costs.

Trend Analysis for each KPI

No more siloed.

It's real-time data.

Make better decisions using centralized real-time insights easily accessible to all teams.

50+

Automated Reports KPIs

Root Cause Analysis

Streamline process and eliminate guesswork - find bottlenecks faster and act proactively!

Planning and Budgeting

Efficiently allocate resources and optimize the new budget with annual loss and cost analysis.

Analyze over 50 reports offered by Kypeco, providing deeper insights into operations and critical data points. Personalize for your brand, and share with colleagues and management, leading to informed business decisions.

We handle your manufacturing report generation so you can focus on what really matters - boosting your production!

Get Reports on Microsoft Teams

Export to PDF

or send over Email.

Want an eco-friendly option? Export to PDF for paperless, or send via an email. It's your choice!

<15 sec

All Insights and Analytics

One-click Insights

Instantly access reports with a single click - no more calculations and doc formatting.

Automated Reports

Now you can forget to send the monthly reports on time. Let Kypeco do it for you!

<15 min

Tailor Your User Experience with Customization: Design Our Platform Your Way!

A white-labeled platform that offers full customization and branding options to suit your business needs. Not only will this enhance your brand identity, but with the ability to add language localization and workflows, you can create a tailored solution that aligns with your business processes.Experience the power of a platform that truly represents your brand - with Kypeco.

Revolutionize production with customized KPIs & OEE Benchmarks. Prioritize critical issues, optimize resources, and achieve better results.

One-time process of setting up reasons applicable to your manufacturing process; get periodic updates on each to streamline the process.

Define SKUs with their production rate and cost. Once defined, you can set up work-orders with a single tap, providing real-time visibility.

Import all equipment used in the production processes with estimated time to repair and replace to maintain a lifetime of equipment.

Prefer to operate without work orders? Optimize production processes by setting hourly production targets once.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Empowering Your Team with a Modern Digital Platform

With our innovative digital platform, your manufacturing team can collaborate seamlessly and optimize productivity. From real-time data insights to streamlined workflows, our solution empowers your team to work smarter, not harder.